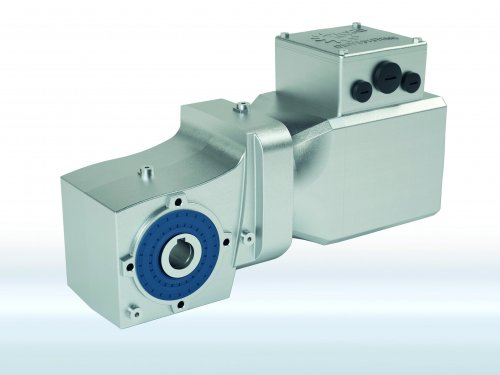

NORD DRIVESYSTEMS presented a new synchronous motor with a significant higher energy efficiency (IE5+). This new motor can be supplied without a fan and with very smooth surfaces. It can be combined with the nsd tupH surface treatment. It is therefore optimally suited for use in intralogistics and wash-down applications.

The new IE5+ synchronous motors are suitable for intralogistics and wash-down applications as a system solution with gear units and inverters from NORD DRIVE SYSTEMS.

The new IE5+ synchronous motors are suitable for intralogistics and wash-down applications as a system solution with gear units and inverters from NORD DRIVE SYSTEMS.

The energy-efficient latest generation permanent magnet synchronous motor has considerably lower losses than the current IE4 series. The unventilated smooth motor achieves its high efficiency that, at times, is significantly above efficiency class IE5 via a wide torque range - and is optimally suitable for the operation in the partial load range. The compact IE5+ motor offers a high power density with less installation space and will be initially launched in a size for power ranges from 0.25 to 1.1 kW with a continuous torque from 1.6 to 4.8 Nm and speeds from 0 to 2,100 min-1. The motor can be directly mounted according to NEMA or IEC. The motor concept will be gradually extended with more sizes and powers. It is ideal for use in hygiene-sensitive and harsh environments because it is easy to clean, corrosion-resistant and wash-down capable. nsd tupH surface treatment and IP69K protection class are optionally available, as well as an integrated mechanical brake. An integrated encoder is part of the standard equipment. The new IE5+ motor can be combined with NORD gear units and drive electronics as a modular system and will be available from the second quarter of 2020.

Corrosion Protection Through Surface Treatment

The nsd tupH surface treatment offered by NORD is an outstanding corrosion protection for gear units, smooth surfaced motors, frequency inverters and motor starters in wash-down optimised cast aluminium housings. The drives are easy to clean and largely resistant to acids and alkalis. It is even possible to use high-pressure cleaners or apply aggressive media. The fanless smooth surfaced motors prevent the spreading of germs and run very quietly.