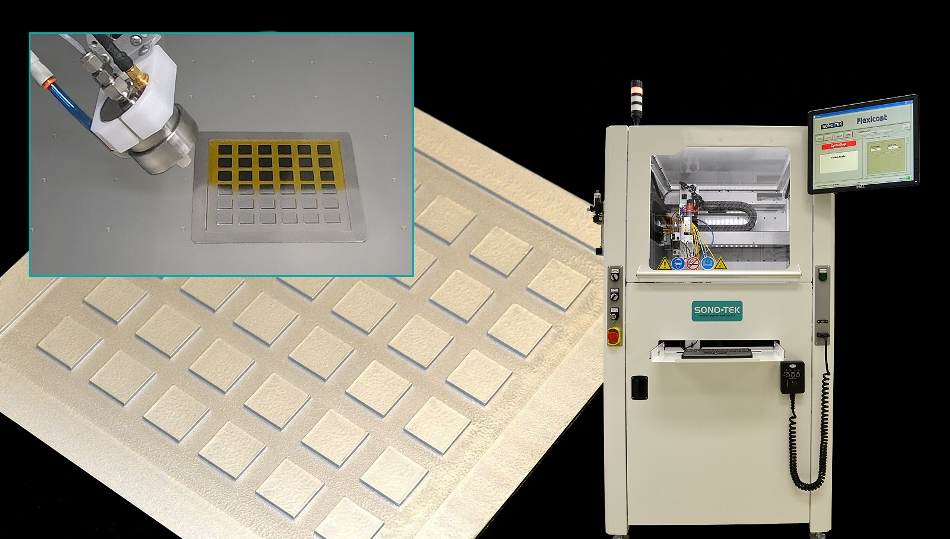

Sono-Tek Corporation announces the release of a new ultrasonic coating system, the FlexiCoat EMI, specifically designed for conformal spraying of EMI (Electromagnetic Interference) shielding material onto semiconductor packages.

This new market is seeing growing interest and activity as a result of smaller devices requiring improved EMI shielding protection properties. Conventional techniques such as shield cans and SMT clips are inadequate for newer small devices. Ultrasonic coating is a cost-effective, faster and simpler alternative to expensive sputtering-based coating equipment.

Sono-Tek’s FlexiCoat EMI is an automated XYZ coating system specifically engineered and proven to spray copper and silver-filled shielding materials with precise control of coating characteristics and little overspray.

Sono-Tek ultrasonic nozzles are widely known for their low/no maintenance, non-clogging, high uniformity and highly repeatable performance. A special ultrasonic nozzle configuration was developed for these EMI applications to provide a more targeted spray area that reduces overspray drastically when compared with all other spray types. This new nozzle design is fully integrated into the FlexiCoat EMI system, along with an array of application-driven features to make the system a full coating solution for EMI shielding coatings.

Some features of the FlexiCoat EMI system include:

- 500x500 mm slides, conveyor and pumping system

- Proprietary ink mixing system to ensure ink stability over time

- UPH/throughput is significantly faster than sputtering at 1/10 the price

- Compatible with ink formulations from Tatsuta and other ink providers

- Uniform shielding coverage on top and sides of package is achieved using nozzle tilt

- Top surface: sidewall thickness ratio of 1: 0.6 ~ 0.7

Bennett Bruntil, Sono-Tek’s Vice President of Sales & Marketing, said: “Our entry into this growing semiconductor application was a natural outgrowth of our semiconductor coating expertise in other applications. Our equipment is quickly proving to be an excellent fit for companies looking for an effective, low-cost alternative to sputtering for deposition of new copper and silver-filled epoxy materials on the market.