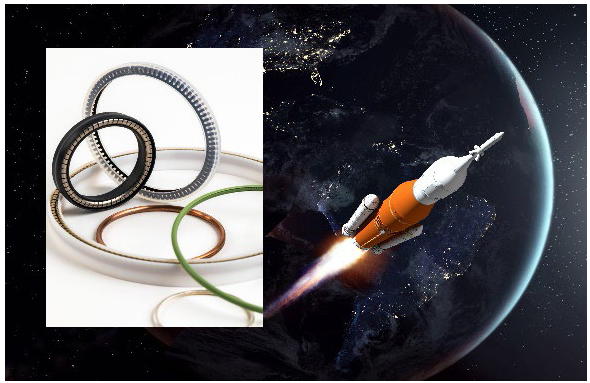

Omniseal Solutions, a designer, engineer and manufacturer of critical, engineered seals and polymer material solutions, will be exhibiting at the 36th Space Symposium at Booth #1172, sharing their expanded sealing solutions portfolio that now includes both polymer seals and metal seals. Recent acquisitions of American Seal & Engineering and HTMS businesses, specialists in metal sealing technology for a combined 60 years, have strengthened Omniseal Solutions’ portfolio and provides access to a complete system of polymer and metal seal solutions that address extreme temperature and pressure challenges often encountered in the space industry.

The expanded portfolio supports their existing space customers as well as emerging global players in the industry, including start-ups, private companies and public agencies. This selection of seals also complements their portfolio of specialty material solutions: Rulon® PTFE compounds and Meldin® thermoset polyimides that have been beneficial in low orbit space applications such as satellite systems. These low weight polymers are used in satellites most often as “tribological” components in the form of bearings and bushings. One prime example can be found in the solar array deployment system that is folded when the satellite is launched and then opens up as soon as the satellite reaches its targeted orbit. A large number of bushings is needed to ensure the deployment is accomplished with low friction and therefore with low energy as needed. Similar applications can also be found in the deployment of antennas and other moving components in a satellite. The key and beneficial properties that both Rulon® and Meldin® material grades can provide in satellite applications are low outgassing, long lifetime (10 to 15 years is a typical requirement), electric and thermal insulation and radiation resistance.

Held from March 30 to April 2, at the Broadmoor Hotel in Colorado Springs, Colorado, the Space Symposium gathers key sectors of the space community from various nations including space agencies; commercial and military businesses; national security and intelligence organizations; government agencies and organizations; research and development facilities; and educational institutions.

This year, Omniseal Solutions not only presents solutions that are helping the space customer tackle future visionary projects but also those with a proven pedigree. Their OmniSeal® RACO® spring-energized seal has been used in many space applications since the start of the NASA program 60 years ago, e.g., Apollo program, space shuttle program, Mars Rover exploration program and Space Launch System (SLS) program. As a way of sharing their decades of knowledge and to help engineers and manufacturers in the space industry gain critical engineering insights, Omniseal Solutions recently released a special technical white paper that explains other stressing factors that affect sealing performance aside from leakage rate. Titled “Polymer & Metal Sealing Solutions in Critical Cryogenic Space Applications: Going Beyond Leakage Rate,” the white paper details key as well as overlooked factors related to seal selection for core systems in extreme environments as experienced in cryogenic fuel tanks, feedlines and fuel valves. Download the free paper or read special space blog topics.