With Australia having a vast wealth of mineral resources and mining being a key factor in the nations’ economy, understanding mineral deposits is of key importance.

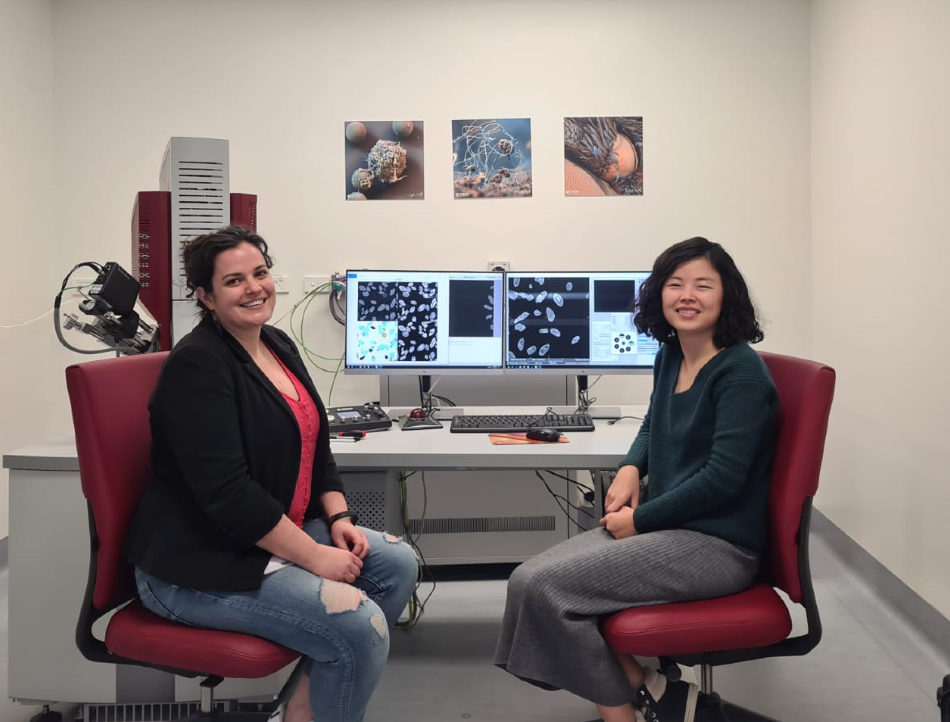

Dr. Crystal Cooper and Dr. Jess Wu from QUT analysing geological materials with their recently installed TESCAN TIMA.

Dr. Crystal Cooper and Dr. Jess Wu from QUT analysing geological materials with their recently installed TESCAN TIMA.

Queensland University of Technology (QUT) is one university that works closely with industry and government bodies to characterise geological materials and has recently installed a TESCAN TIMA automated mineralogy system to keep pace with their demands.

The TESCAN TIMA provides QUT with high-speed, high-throughput mineralogical analysis using multiple EDS detectors working in unison with the high resolution FEG-SEM (Field Emission Gun Scanning Electron Microscope). Sophisticated software enables users to automatically characterise multiple geological samples. In doing so, it meets the requirements of both academic researchers and commercial mining companies involved in exploration geology and process metallurgy.

Despite the complications that have arisen as a result of COVID-19 relating to travel and international transport, the installation and training went smoothly. AXT’s Queensland-based engineer was able to take care of the installation and commissioning. Initial training was simplified as QUT has a similar TESCAN system already. More specific training was carried out remotely using AXT’s experts in Perth at the Automated Mineralogy Incubator who have an in-depth knowledge of the operation of the TESCAN TIMA including measurements and data analysis.

Being housed at the central facility means the system will be available to many users including postgraduates, internal and external researchers as well as industry clients. Several CARF staff have already been training on the use of the system in the short time since it has been installed and are already collecting data. There are plans to train many more users, while the availability of the new capability has stimulated much interest for new projects amongst various collaborators.

Speaking about their recent acquisition Dr. Henrietta Cathey, Research Officer said, “The most exciting aspect of the TIMA so far, for us, is the ability to massively increase the workflow for our metallurgy and geological projects. CARF staff have so far been impressed with the ease of use and the relatively short training times required given the complexity of the instrument.”

This is the sixth TESCAN TIMA system that AXT have installed in Australia. The technology has proven its value in the research sector, but also has direct applicability in minerals exploration and process metallurgy. Northparkes Mines, reputed to be the world’s most automated underground mine have a TESCAN TIMA. It is now the central part of their workflow, linking together numerous departments and streamlining their operation by providing deeper insights into their process in a timely fashion enabling it to be continuously fine-tuned for maximum efficiency.