Entegris, Inc., a world-class supplier of advanced materials and process solutions for the semiconductor and other high-technology industries, announced today the introduction of a unique fluid management system that removes electrostatic charge in the chemical delivery systems that are integral to the manufacture of today’s advanced technology chips.

Entegris' New Innovative ESD Solution. Image Credit: Business Wire

Entegris' New Innovative ESD Solution. Image Credit: Business Wire

Stainless steel fluid management systems traditionally used to transport solvents and other flammable chemicals utilized in semiconductor manufacturing cannot meet today’s increased requirements for ultra low metal impurities. As a result, manufacturers of advanced technology chips are moving away from stainless steel systems to fluoropolymer (PFA) systems. While PFA systems reduce metal contamination introduced by the stainless steel systems, they create a new challenge associated with electrostatic discharge, since PFA is a non-conductive electrical insulator.

According to Brett Reichow, vice president of fluid management in Entegris’ Advanced Materials Handling (AMH) division, “The presence of electrostatic charge accumulation in the fluids that flow through the chemical delivery system can not only compromise the fluid handling components in the system from electrostatic discharge events, it can lead to defects on the silicon wafer. Electrostatic discharge can also create unsafe conditions in the semiconductor fabrication process,” he said.

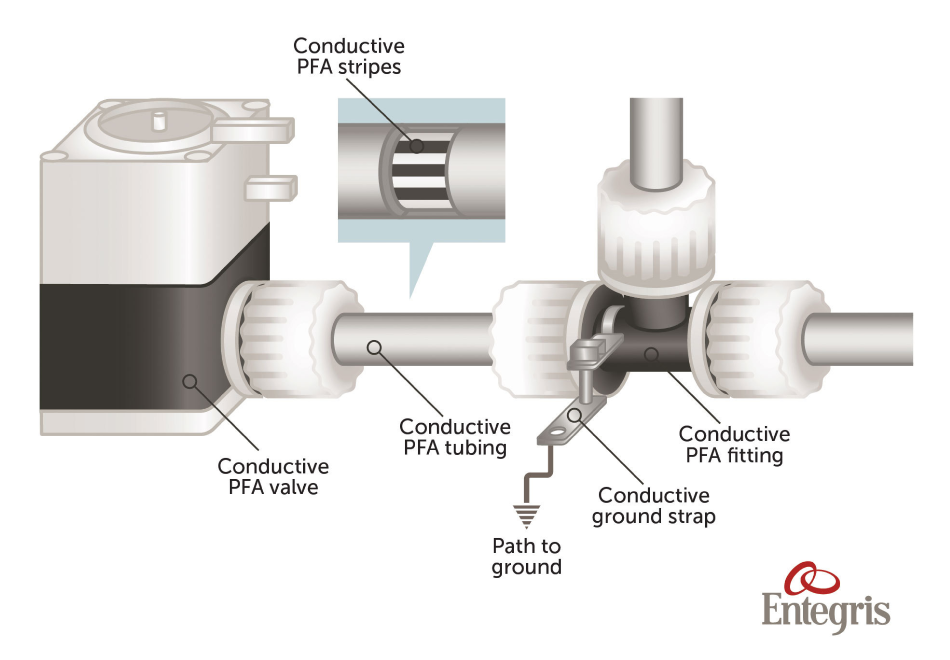

Entegris has developed a solution using new materials that has proven successful in reducing the accumulated electrostatic charge in both the fluid flowing through the tubing as well as any charge that might build up outside the tubing. “The PFA tubing of Entegris’ innovative system,” Reichow said, “has conductive stripes on the inside, and the fittings are manufactured from a conductive PFA to create a path to ground when the sealing area contacts the conductive stripes.”

According to Bill Shaner, senior vice president of the AMH division, Entegris benefitted from more than three decades of supplying innovative connection technology for high-purity handling markets to develop its solution to ESD, which simultaneously improves safety and reduces the potential for defects. “We have used our proprietary manufacturing equipment and processes to co-extrude ultrapure PFA and conductive PFA to create one single layer. This unique PFA construction results in low metallic contamination, eliminates delamination risk and potential entrapment areas, therefore maintaining high chemical purity. This new solution decreases safety risks and also minimizes the risk of property damage. In addition, because the tubing is translucent, it allows visual inspection of the fluid flowing through the system,” Shaner said.

Results from metal extraction testing that Entegris has performed on the new system indicate that it maintains a level of purity similar to the standard PFA tube. Also, a third party testing firm confirmed the satisfactory grounding performance of the new system.

“Entegris’ new patent pending ESD system,” Shaner said, “is another key innovation designed to help the microelectronics industry continue progressing toward cleaner chemical delivery systems to meet the needs of advanced process nodes.”