With the newly developed Vitralit® UD 1405 adhesive, Panacol has created an innovative adhesive system for fibre and filament winding. For high efficiency, Vitralit® UD 1405 can be applied during the winding process and immediately cured with high intensity LED curing systems from Dr. Hönle AG. This adhesive and curing system is ideal for Carbon or Glass Fibre filament winding associated with Carbon Fibre Reinforced Polymer (CFRP) or Glass Fibre Reinforced Polymer (GFRP) manufacturing processes.

Vitralit® UD 1405 can be used to wrap components such as hybrid rotor shafts for electric motors and high-voltage surge arresters. The adhesive-coated fibre-reinforced windings can be then be quickly cured with UV/visible light. This innovative winding process is extremely space and time-saving, and can produce significant processing cost savings.

Panacol’s Vitralit® UD 1405 is a transparent, solvent-free, one-component epoxy. Due to its low viscosity, Vitralit® UD 1405 has very good wetting properties. It can be cured in seconds by irradiation with UV (365nm) or Visible (405nm) light wavelengths. Depending on the fibre material and the wavelength used, layer thicknesses of several millimetres can be achieved exclusively by UV/Visible light curing. This epoxy can also be thermally cured after UV exposure to ensure that a complete cure is secured in areas shadowed from the UV light. For example, fibres or filaments can first be pulled through an adhesive bath, then wound onto the rotor or respective cylinder, and cured with UV or visible light. A secondary thermal cure will ensure that the layers of coated windings below the surface become fully cured.

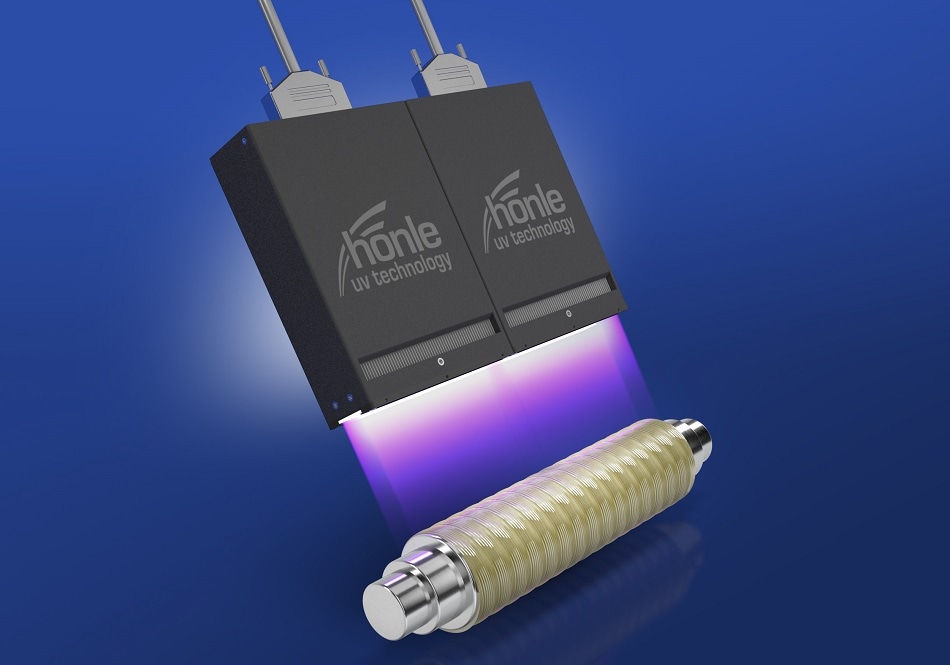

For the most efficient UV curing system for fibre and filament winding processes, the LED Powerline AC/IC 820 HP from UV specialist Hönle is the perfect choice. With intensities of up to 16,000 mW/cm², this LED system ensures very fast curing. Its light emission window is available in two standard sizes, 82 mm x 20 mm and 122 mm x 20 mm, which can be extended without gaps by stringing together multiple modules. When developing the LED Powerline AC/IC 820 HP, special attention was paid to a slim design. This makes it ideal for use where space is at a premium, such as automated winding equipment.

The powerful LED Powerline AC/IC 820 HP can be powered and controlled using the optionally available LED powerdrive IC as a plug&play solution, or by using a customer supplied external power supply and PLC. This makes the LED Powerline an ideal solution for integrating high power LED curing systems into automated assembly processes.

After curing, Vitralit® UD 1405 is electrically insulating, shows minimal shrinkage and remains resistant at temperatures from -40° to 180°C. A glass transition temperature of over 130°C ensures reliable performance even under dynamic load at elevated temperatures.