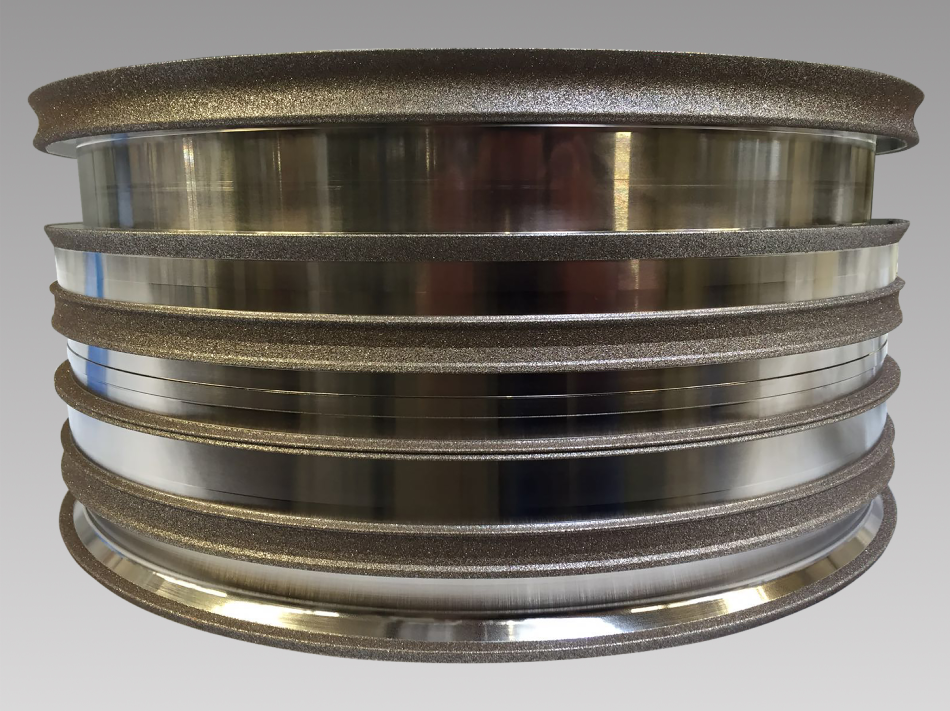

Saint-Gobain Abrasives, one of the world’s largest abrasives manufacturers, announced the introduction of its new Norton Winter AEON Electroplated Grinding Wheels for high precision applications in the automotive, medical and aerospace markets. An innovative design and manufacturing process give AEON wheels the ability to hold an extremely tight profile tolerance of ± 5 µm at a maximum wheel diameter of ~24" (600 mm) and width ~12" (300 mm), weighing up to 551 lbs (250 kg).

Norton Winter AEON Grinding Wheels have a single usable abrasive layer design, with diamond or cBN particles mechanically fixed onto the core surface by an electrochemical process of nickel deposition. This unique layer design provides high grit retention levels for long wheel life. To save costs, the wheel core can be re-used. Once the abrasive grains are worn, the core of the wheel can be re-plated with new diamond or cBN grain in a continuous re-plating cycle.

"We are pleased to offer our customers with new high precision electroplated grinding wheels which are custom designed to meet their application requirements," said Andy Schoch, Product Manager for Single Layer Products, Norton | Saint-Gobain Abrasives. "New AEON Grinding Wheels provide up to a 50% increase in production efficiency, wheel life and number of re-platings."

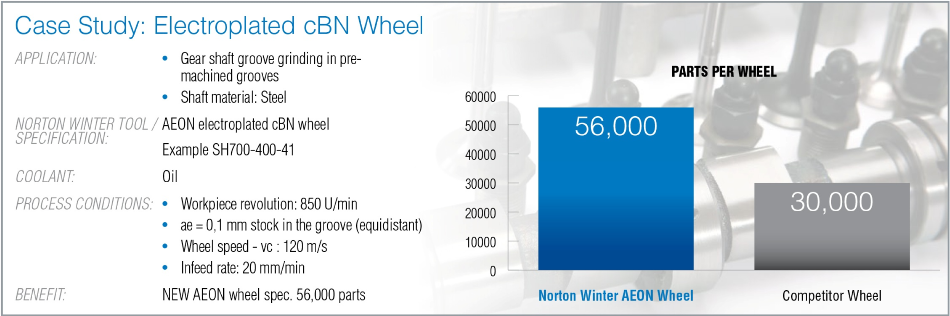

Below is a case study showing a Norton Winter AEON Wheel that was approximately 50% more productive when finishing parts when compared with a competitor's wheel.

For more information, visit https://www.nortonabrasives.com/sga-common/files/document/flyer-wheels-electroplated-winter-aeon-8820.pdf.