Nov 12 2020

Camels have developed an apparently counterintuitive method to keep themselves cool and simultaneously preserve water in sweltering desert surroundings: The bodies of these animals are covered with a dense coat of insulating fur.

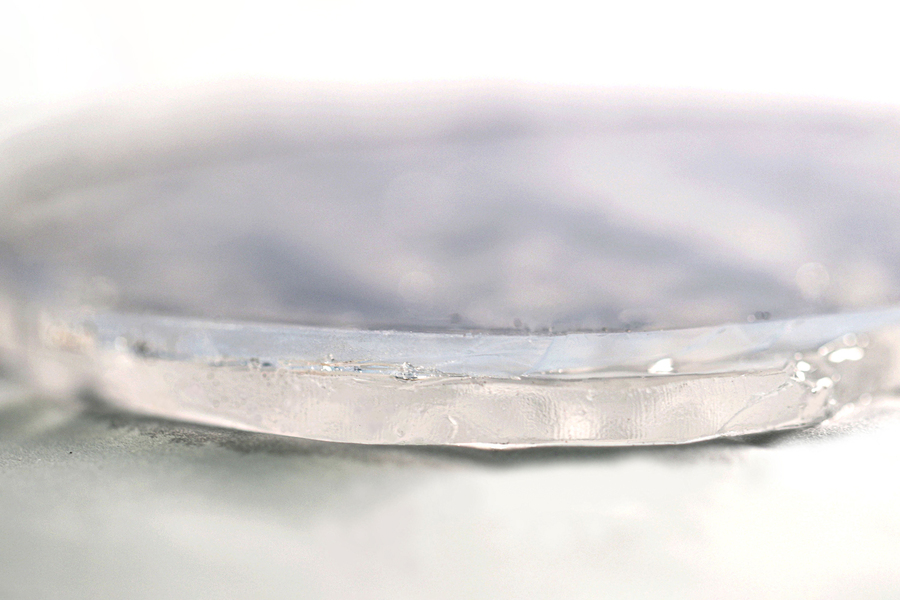

MIT researchers have developed a two-layer passive cooling system, made of hydrogel and aerogel, that can keep foods and pharmaceuticals cool for days without the need for electricity. In this photo showing a close-up of the two-layer material, the upper layer consists of aerogel and the bottom layer of hydrogel. Image Credit: Courtesy of Jeffrey Grossman, et. al.

MIT researchers have developed a two-layer passive cooling system, made of hydrogel and aerogel, that can keep foods and pharmaceuticals cool for days without the need for electricity. In this photo showing a close-up of the two-layer material, the upper layer consists of aerogel and the bottom layer of hydrogel. Image Credit: Courtesy of Jeffrey Grossman, et. al.

MIT researchers have now designed a novel system by adopting the same kind of approach. This system could help keep fresh produce, pharmaceuticals, and other similar things cool in hot surroundings, without having to depend on a power supply.

A majority of individuals would not think of putting on a camel-hair coat on a scorching day, but as a matter of fact, many people living in desert regions indeed wear heavy outer clothes for basically the same reason.

But it turns out that a person’s clothing, or a camel’s coat, can help decrease moisture loss and simultaneously allow the evaporation of enough sweat to offer a cooling effect. Furthermore, tests have demonstrated that a shaved camel loses as much as 50% more moisture when compared to an unshaved one, under the same conditions, stated the investigators.

The novel system designed by the MIT team utilizes a two-layer material to get an analogous effect. The bottom layer of the material, replacing for sweat glands, contains a gelatin-like substance called hydrogel that mostly contains water, retained in a sponge-like matrix from which the water can evaporate more easily. This is subsequently concealed with an upper layer of aerogel, which serves as a kind of fur by enabling the vapor to flow through and keeping out the external heat.

Although hydrogels are already employed for certain cooling applications, field tests and comprehensively analysis have demonstrated that this novel two-layer material, which measures less than half an inch in thickness, can offer a cooling effect of over 7 °C for five times longer when compared to the hydrogel alone—over eight days against less than two.

MIT postdoc Zhengmao Lu, along with graduate students Elise Strobach and Ningxin Chen, Research Scientist Nicola Ferralis, and Professor Jeffrey Grossman, head of the Department of Materials Science and Engineering, has recently reported these findings in an article in the Joule journal.

According to the researchers, the novel system could be used for packaging food products to retain their freshness and it may also provide more distribution options to farmers, allowing them to sell their perishable crops. The system may also enable drugs, such as vaccines, to be stored safely as they are transported to distant places.

Apart from offering a cooling effect, the passive system, which is solely powered by heat, can decrease the temperature variations that are experienced by the goods, preventing spikes that can speed up spoilage.

Ferralis explained that these packaging materials could ensure continuous protection of perishable medicines or foods all the way from the factory or farm, via the distribution chain, and then all the way to the home of the consumer.

On the other hand, present-day systems that depend on storage facilities or refrigerated trucks may leave gaps where spikes in temperatures can occur at the time of loading and unloading.

What happens in just a couple of hours can be very detrimental to some perishable foods.

Nicola Ferralis, Research Scientist, Department of Materials Science and Engineering, MIT

The two-layer system uses basic raw materials that are less costly—for example, the aerogel is produced from silica, which is basically beach sand, both economical and abundantly available.

However, the processing equipment required for producing the aerogel is bulky and costly and, therefore, that aspect will need to be further developed to upgrade the system for beneficial applications. Nevertheless, at least one startup firm is already working on designing such large-scale processing to utilize the material for making thermally insulating windows.

The fundamental principle of using water evaporation to offer a cooling effect has been in use for many years in one form or another, such as the double-pot systems used for preserving foods. These systems utilize a pair of clay pots, one inside the other, with a wet sand layer in between. Water vaporizes from the sand out via the outer pot and leaves the inner pot cooler.

However, the concept of integrating such evaporative cooling with an insulating layer, as done by camels and some other animals in deserts, has actually never been used on human-designed cooling systems before.

For applications such as food packaging, the transparency of the aerogel and hydrogel materials is significant, enabling the food condition to be clearly observed via the packaging material.

However, for other kinds of applications such as space cooling or pharmaceuticals, a thick insulating layer may be used instead, offering even more choices for designing the materials for specific applications, stated Lu, who was the lead author of the study.

The hydrogel material is made up of 97% water, which slowly evaporates away. During the experiment, a 5-millimeter layer of hydrogel, concealed with 5 millimeters of aerogel, took 200 hours to lose all its moisture, when compared to 40 hours for the bare hydrogel material.

The cooling level of the two-layered material was somewhat less, a reduction of 7 °C (around 12.6 °F) absent 8 °C (14.4 °F). However, the effect lasted relatively longer. When the moisture evaporates from the hydrogel material, the material can be subsequently recharged with water to allow the cycle to start again.

Particularly in developing nations, where access to electricity is usually restricted, materials like these could provide a significant advantage, added Lu.

Because this passive cooling approach does not rely on electricity at all, this gives you a good pathway for storage and distribution of those perishable products in general.

Zhengmao Lu, Postdoc, MIT