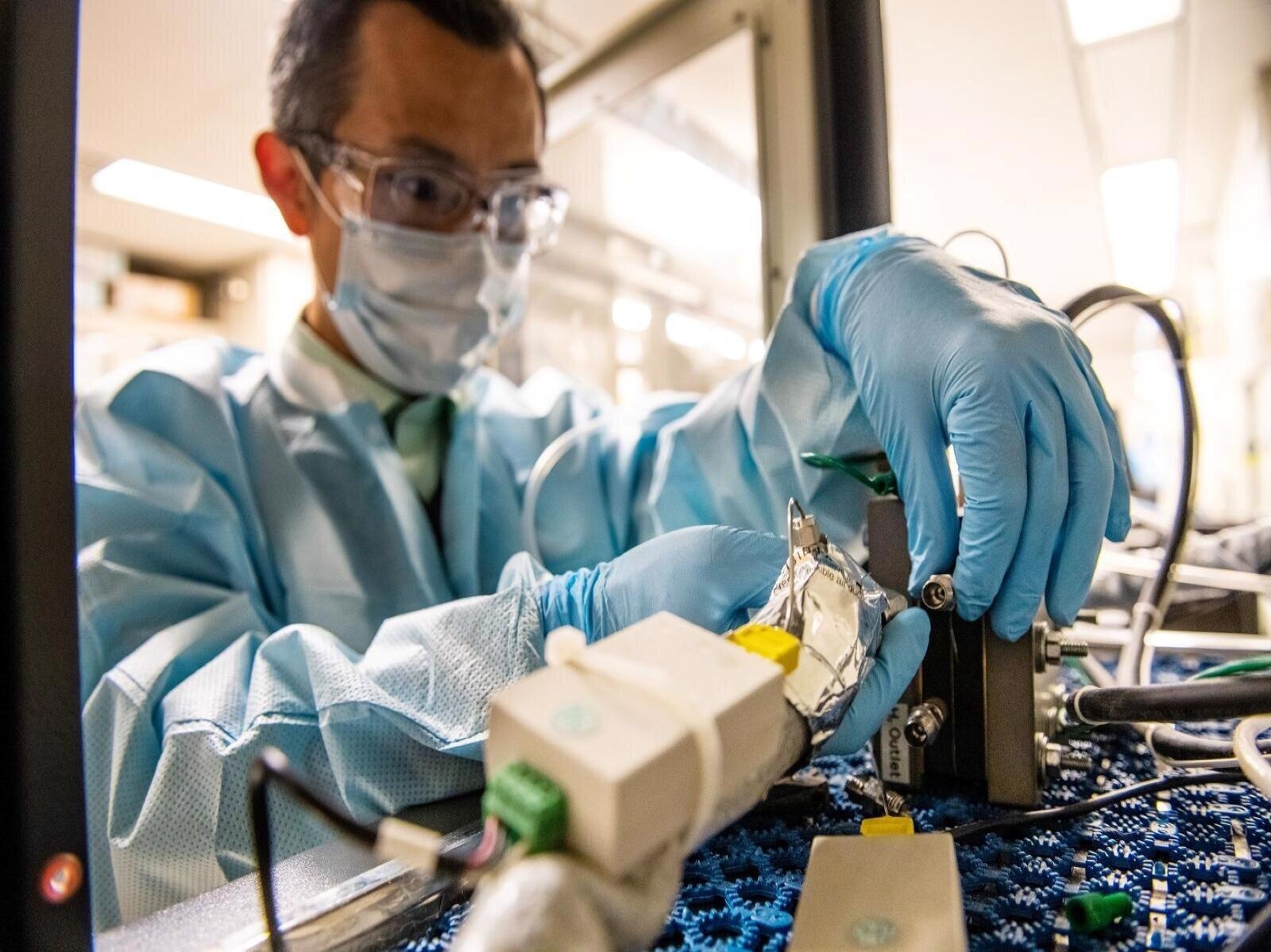

Image Credit: Pacific Northwest National Laboratory

New research has found cobalt could be a cheaper alternative for platinum in PEM fuel cells, a discovery that could lead to increased usage and reduced dependence on fossil fuels.

Electric vehicles that use fuel cells are an important step in cutting greenhouse emissions and our attempts to limit climate change. These cells can be used to generate electricity from oxygen and compressed hydrogen, thus reducing the need for fossil fuels.

One of the problems that hinder the widespread roll-out of this technology is that the cost of fuel cells can be quite restrictive. This is certainly the case for Proton exchange membrane (PEM) fuel cells — the best candidates for powering cars and other vehicles.

These fuel cells need very active catalysts to assist in the oxygen reduction that powers them. The platinum metals that are currently used as catalysts — materials that speed up chemical reactions without being changed or consumed themselves — in these highly efficient and clean fuel cells account for half of a unit's total cost.

Thus, finding a cheaper alternative catalyst for PEM fuel cells that could make these devices much more affordable is an area of intense interest for manufacturers and researchers alike.

That is exactly the breakthrough that a multi-institutional research team led by materials scientists from Pacific Northwest National Laboratory (PNNL) believe they have hit upon. The researchers have designed an active catalyst that is also durable and doesn't rely on expensive platinum.

The team's research is published in the latest edition of the journal Nature Catalysis¹.

Making the Transition to Cheaper Fuel Cells

Fuels cells work like batteries but without running down or needing a recharge — producing energy as long as they have fuel. They consist of two electrodes sandwiched around an electrolyte. PEMs work by using a proton-conducting polymer membrane as an electrolyte and hydrogen as a fuel. But the process they rely on, in turn, depends on a catalyst.

Scientists have been searching for an alternative for platinum as a catalyst in PEM fuels for some time. The main focus of this work has been with other metals, mainly transition metals like iron. The problem with the use of these metals is that they break down quickly in PEMs — which present highly acidic conditions.

To combat this, the team turned to cobalt — a transition metal that is far less reactive than iron—with the hope that it can withstand the acidic environment of PEM fuel cells for longer. Of course, cobalt also carries with it the benefit of being far more abundant, and cheaper, than platinum.

The downside of cobalt is the fact that its lack of reactivity makes it a less efficient catalyst than iron.

We knew that the configuration of cobalt with nitrogen and carbon was key to how effectively the catalyst reacts and that the active site density was critically important for performance. Our goal was to really improve the reaction activity of cobalt-based catalysts.

Yuyan Shao, Materials Scientist, PNNL

Forcing Cobalt to Over React

The first step the team took to try and force cobalt to react was to immobilize it in the micropores of a metal-organic framework called zeolitic imidazolate. This served as a protective fence limiting the mobility of the cobalt atoms, also preventing the atoms from clustering together.

The team then used a thermal decomposition process called pyrolysis — which is more commonly used to treat organic materials — to transform the penned atoms into catalytically active sites. These sites were still sat with the framework structure they had created.

The team found the density of the active sites had increased. This had the knock-on effect of considerably boosting their reactivity. In fact, the reactivity that the team observed represents the highest seen in a non-platinum-based catalyst thus far.

As hoped, the team also found the cobalt model was far more durable than iron-based catalysts, finding that it resisted 'demetallization' — the leaching out of metal ions — for far longer. This means that it was able to maintain catalytic activity for an extended period of time.

The team's research could boost the efficiency of PEM fuel cells whilst simultaneously making them cheaper. There's no doubt this would be seen as a massive boon for the automobile industry that is desperately trying to reduce carbon emissions.

In the end, we were able to not only improve the activity of the cobalt-based catalyst, but we significantly improved the durability. Our further investigation led us to discover the mechanisms that typically degrade these types of catalysts.

Yuyan Shao, Materials Scientist, PNNL

References

Shao. Y., Xie. X., He. C., et al, [2020], 'Performance enhancement and degradation mechanism identification of a single-atom Co–N–C catalyst for proton exchange membrane fuel cells,' Nature Catalysis, [https://doi.org/10.1038/s41929-020-00546-1]

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.