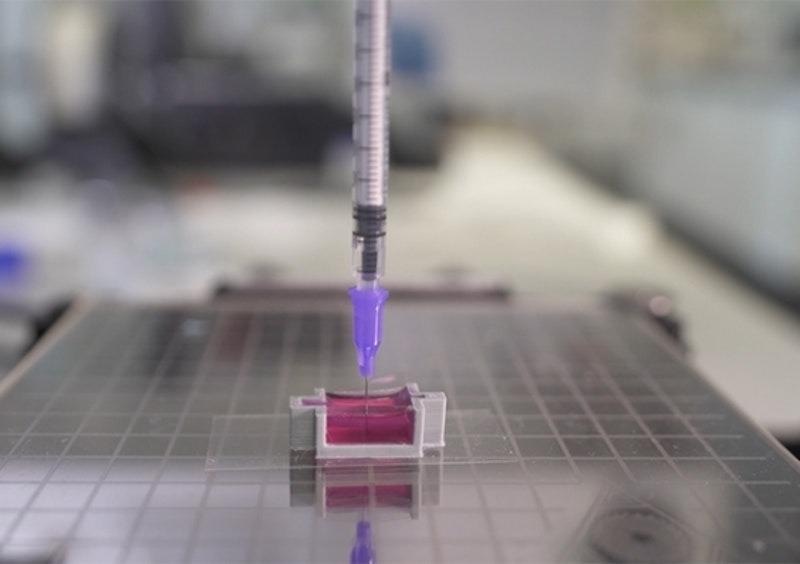

Image Credit: University of New South Wales

A novel technique could lead to 3D printed bones that provide a more natural and less intrusive alternative to bone grafts.

Bone breakage and loss through illness is not uncommon. Currently, we deal with these things by performing bone grafts, but this process requires taking a section from another bone, cutting it to fit in place, and holding it steady with metal plates and scaffolding that has to be removed in further operations. Even worse, if too much bone is missing or irreversibly damaged, the only option is amputation.

3D printed structures can be precisely modeled by scanning the area to be treated, meaning that the widespread adoption of 3D printed bones could solve these issues and make bone grafts a thing of the past.

Researchers from the University of New South Wales (UNSW), including Dr. Iman Roohani from the institute’s School of Chemistry and Associate Professor Kristopher Kilian, have put a new spin on the 3D printing of bone structures. One that could see 3D printers deployed in every operating theater right where they are needed.

The team has pioneered a unique technique that uses an ink containing calcium phosphate — a mineral that plays a major role in natural bone formation. The technique referred to as Ceramic Omnidirectional Bioprinting in Cell-Suspensions (COBICS) could allow surgeons to print structures that can be submerged in water and hardened within just minutes resembling natural bone. Even more revolutionary, the structures contain living cells that continue to grow after they are implanted.

The team’s breakthrough is discussed in a new report published by IDTechEx¹ and in a paper published in the journal Advanced Functional Materials².

Building Upon ‘Bone Printing’ Methods

Whilst the 3D printing of bone substitutes is by no means ‘new’, the team’s technique has significant advantages over current platforms. Particularly, it’s the first method that allows such structures that contain living cells to be printed at room temperatures. Secondly, it does this without the use of potentially dangerous chemicals or the need for radiation.

These characteristics could allow the technique to be widely distributed and employed in a variety of locations, particularly right where it is needed and when it is needed.

This is a unique technology that can produce structures that closely mimic bone tissue. It could be used in clinical applications where there is a large demand for in situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected.

Dr. Iman Roohani, the University of New South Wales

Kilian points out, that until the team’s breakthrough the creation of a 3D printed structure that contains living cells has involved doing so in the lab and with the use of furnaces to achieve high temperatures and toxic and potentially harmful chemicals.

“This produces a dry material that is then brought into a clinical setting or in a laboratory, where they wash it profusely and then add living cells to it,” Kilian continues. “The cool thing about our technique is you can just extrude it directly into a place where there are cells, like a cavity in a patient’s bone.”

Kilian also points that with the team’s technique, surgeons can directly enter a patient’s bone and in that immediate area print a structure that already contains living cells. “There are currently no technologies that can do that directly,” he adds.

Scientists use a novel ink to 3D print ‘bone’ with living cells

Developing a ‘Living Ink’

The ink that the team developed can quickly form a structure that is similar in chemical composition to natural materials that build bones. It does this by employing a setting mechanism that creates interlocked bone nanoparticles from nonorganic ink.

The ink is formulated in such a way that the conversion is quick, non-toxic in a biological environment and it only initiates when ink is exposed to the body fluids, providing an ample working time for the end-user, for example, surgeons.

Kristopher Kilian, Associate Professor, the University of New South Wales

Combining the ceramic ink with collagen-like material that contains living cells results in the creation of tissue that can be used in a wide range of applications. The team says that even beyond engineering new bone this includes, modeling disease, and screening for drugs and other substances.

The technique is currently very much in its early phases. The team will now attempt tests that observe how the bone-like material’s livings cells continue to grow after they are implanted into existing bone tissues.

“I imagine a day where a patient needing a bone graft can walk into a clinic where the anatomical structure of their bone is imaged, translated to a 3D printer, and directly printed into the cavity with their own cells,” Kilian concludes. “This has the potential to radically change current practice, reducing patient suffering and ultimately saving lives.”

References

¹Tsao. N., [2021], ‘3D Bioprinting 2018–2028: Technologies, Markets, Forecasts,’ IDTechEx, [https://www.idtechex.com/en/research-report/3d-bioprinting-2018-2028-technologies-markets-forecasts/592]

² Romanazzo. S., Molley. T. G., Nemec. S., et al, [2021], ‘Synthetic Bone‐Like Structures Through Omnidirectional Ceramic Bioprinting in Cell Suspensions,’ Advanced Functional Materials, [https://doi.org/10.1002/adfm.202008216]

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.