Feb 5 2021

In this modern age, plastics are one of the most successful materials. But they also contribute to a huge problem of waste.

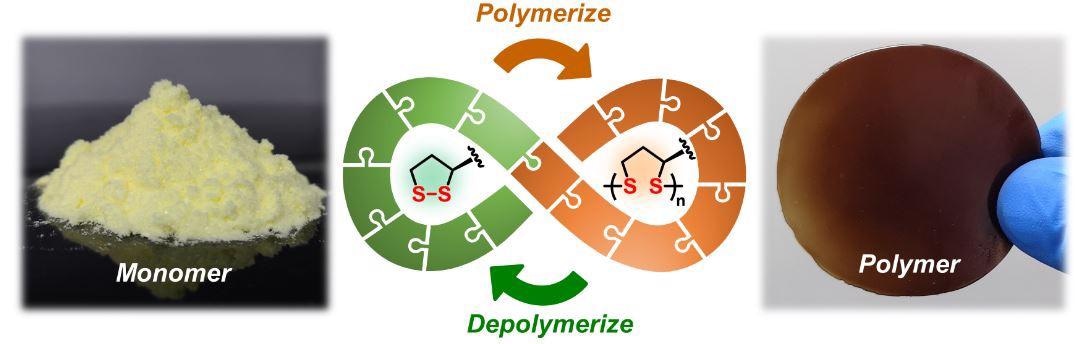

Scientists from the University of Groningen (The Netherlands) and the East China University of Science and Technology (ECUST) in Shanghai produced different polymers from lipoic acid, a natural molecule. These polymers are easily depolymerized under mild conditions. Some 87% of the monomers can be recovered in their pure form and re-used to make new polymers of virgin quality. Image Credit: Qi Zhang

Scientists from the University of Groningen (The Netherlands) and the East China University of Science and Technology (ECUST) in Shanghai produced different polymers from lipoic acid, a natural molecule. These polymers are easily depolymerized under mild conditions. Some 87% of the monomers can be recovered in their pure form and re-used to make new polymers of virgin quality. Image Credit: Qi Zhang

Researchers from the University of Groningen (The Netherlands) and the East China University of Science and Technology (ECUST) in Shanghai generated various polymers from lipoic acid, which is a natural molecule.

The new polymers tend to depolymerize easily under mild conditions. Nearly 87% of the monomers can be retrieved in their pure form and can be reused to create new polymers of virgin quality. The process has been explained in an article published in the journal Matter on February 4th, 2021.

An issue with recycling plastics is that it generally leads to a product of lower quality. The optimal results are achieved by chemical recycling, where the polymers are disintegrated into monomers. But this depolymerization is usually very hard to achieve.

Researchers from the Feringa Nobel Prize Scientist Joint Research Center, a collaboration between the University of Groningen and ECUST, have created a polymer that can be formed and completely depolymerized under mild conditions.

Perfect Building Block

We found a way to produce polymers from the natural molecule lipoic acid in a very controlled way is a beautiful molecule and a perfect building block that was created by nature. This process was known before, but we managed to find a way to control it and to create long polymers.

Ben Feringa, Professor of Organic Chemistry, University of Groningen

The molecule features a ring structure that includes a sulfur-sulfur bond. When this bond breaks, the sulfur atoms can react with those of another monomer.

Elastic Material

The molecule includes a carboxyl group that reacts readily with metal ions. These can crosslink the polymers, which leads to the formation of an elastic material. When the molecule is dissolved in water with sodium hydroxide and the water is evaporated, a stronger polymer film is produced via ionic bonds.

Since the polymerization is realized via reversible bonds, the material is also self-healing, explained Feringa: “When it is cut, you can simply press the ends together and they will reconnect in a few minutes.”

Reversible Polymerization

A major part of the study was performed by Qi Zhang, first as a PhD student at ECUST in Shanghai and later as a postdoctoral researcher at the University of Groningen. “Lipoic acid is a natural small molecule with an elegant structure. We didn’t have to do any tedious re-designing of the monomer to achieve a fully reversible polymerization,” he noted.

When the polymers are simply exposed to sodium hydroxide, they get dissolved into monomers.

By adding a little acid, the monomers precipitate and can be recovered. The quality of these recycled monomers is identical to that of the original material.

Qi Zhang, Postdoctoral Researcher, University of Groningen

Recycling Without Loss of Quality

Our experiments show what is possible with these monomers. We can even recycle the material into monomers several times, without loss of quality. This is a proof of principle. We are conducting experiments now to create polymers with new functionalities and to better understand the polymerization and depolymerization processes.

Ben Feringa, Professor of Organic Chemistry, University of Groningen

But realizing industrial uses of this new polymer has a long path to tread. Moreover, though 87% of the monomers can be retrieved already, the researchers wished to get as close to 100% as possible.

“Our experiments show that we can produce, in a controlled fashion, hard and soft, elastic polymers that can be fully depolymerized. This molecule is really very promising,” concluded Feringa.

Journal Reference:

Zhang, Q., et al. (2021) Dual closed-loop chemical recycling of synthetic polymers by intrinsically reconfigurable poly(disulfides). Matter. doi.org/10.1016/j.matt.2021.01.014.