Feb 8 2021

Headed by Nanyang Technological University, Singapore (NTU Singapore), a research team has designed a novel material that can flex and bend 40 times more than its competitors when an electric current is applied on it, paving the way to more improved micro machines.

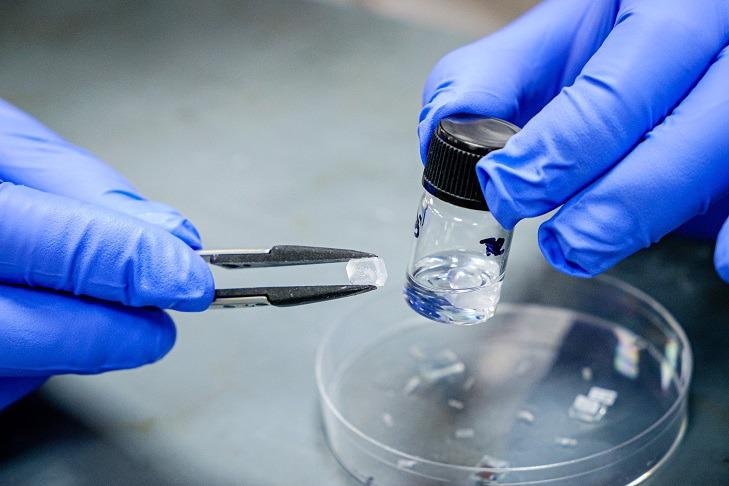

A close up of the new piezoelectric crystal developed by NTU scientists, which can flex up to 40 times more than the conventional ferroelectric crystals typically used in small actuators and sensors. Image Credit: Nanyang Technological University.

A close up of the new piezoelectric crystal developed by NTU scientists, which can flex up to 40 times more than the conventional ferroelectric crystals typically used in small actuators and sensors. Image Credit: Nanyang Technological University.

On the other hand, when the new material is bent, it produces electricity quite effectively and can perhaps be utilized for more improved 'energy harvesting'—possibly recharging batteries in gadgets simply from everyday movements.

The new material is both piezoelectric and electrostrictive. Its electrostrictive characteristics mean it can alter its shape when electricity is applied to it, whereas piezoelectric means the material can transform pressure into electric charges.

Upon applying an electric field, the atoms that constitute electrostrictive materials move and this causes the novel material to deform and flex. Upon compressing piezoelectrics, the pressure is changed to electric charges which build up in the material.

The researchers observed that upon applying an electric field, the novel hybrid material could be strained up to 22%—the maximum strain reported in a piezoelectric material to date.

This exceeds the traditional piezoelectric materials that deform only up to 0.5% when a current flows through it. The innovative material is more energy efficient when compared to other electrostrictive and piezoelectric materials.

Piezoelectric materials are often utilized in electric motors, sensors, loudspeakers and guitars.

For example, a piezoelectric pick-up is a kind of device employed in electric guitars to transform the vibrations from the strings into an electric signal. This signal is subsequently amplified via loudspeakers or processed for music recording.

Ferroelectric crystals were initially identified in 1920 and since then, they have been used for making piezoelectrics for more than seven decades, as they are effortlessly incorporated into electrical devices.

But ferroelectric crystals are fragile and inflexible, and bend just 0.5%, which considerably reduces their application in various electronic devices, like actuators (components that change an electric control signal into mechanical motion, for instance, a valve that closes and opens).

There are a few ferroelectrics that also contain lead, which is harmful, and its prevalence in piezoelectric devices is one of the major reasons why electronic waste cannot be recycled easily.

Conventional ferroelectrics, like perovskite oxides, are also not suitable for flexible electrical devices that make contact with the skin, like wearable biomedical devices that monitor heart rate.

The novel material was developed at NTU by Fan Hong Jin, a Professor from the School of Physical & Mathematical Sciences, and his group, which included his PhD student and the first author of the study, Mr Hu Yuzhong.

Professor Junling Wang from the Southern University of Science and Technology, China, and a former NTU professor at the School of Materials Science and Engineering was also a part of the research team. The study was recently published in the scientific journal, Nature Materials.

Being more than 40 times more flexible than similar electrostrictive materials, the new ferroelectric material may be used in highly efficient devices such as actuators and sensors that flex when an electric field is applied. With its superior piezoelectric properties, the material can also be used in mechanical devices that harvest energy when bent, which will be useful to recharge wearable devices.

Fan Hong Jin, Professor, School of Physical & Mathematical Sciences, Nanyang Technological University

Professor Jin added, “We think we can substantially improve on this performance in future by further optimising the chemical composition, and we believe this type of material could play a key role in the development of wearable devices for the Internet of Things (IoT), one of the key technologies enabling the 4th Industrial Revolution.”

Developing a Flexible Ferroelectric Material

To design a flexible ferroelectric material, the investigators initially altered the chemical structure of a hybrid ferroelectric compound, called C6H5N(CH3)3CdCl3, or PCCF in brief, which can possibly bend up to 100 times more than conventional ferroelectrics.

To further boost the range of movement of the material, the team also altered the chemical composition of the compound by replacing a few of its chlorine (Cl) atoms for bromine (Br), which has almost the same size as that of chlorine, so as to weaken the chemical bonds at particular points in the structure. This process made the material more flexible without impacting its piezoelectric properties.

The novel material can be easily produced and needs only solution-based processing, wherein the crystal forms when the liquid evaporates, which was different from regular ferroelectric crystals that involve the use of energy and high powered lasers to form.

Upon applying an electric field to the novel PCCF compound, the atoms within this compound moved considerably more than the atoms present in the majority of the traditional ferroelectrics, straining up to 22% far more than standard piezoelectric materials.

Other authors of the study include scientists from NTU’s School of Materials Science and Engineering, Facility for Analysis, Characterisation, Testing and Simulation (FACTS), Soochow University, and Southern University of Science and Technology in China.

Journal Reference:

Hu, Y., et al. (2021) Ferroelastic-switching-driven large shear strain and piezoelectricity in a hybrid ferroelectric. Nature Materials. doi.org/10.1038/s41563-020-00875-3.