Feb 8 2021

Silicon anodes are known to considerably increase the capacity of Li-ion batteries, but their performance degrades quickly with use. Although polymeric coatings could be a solution to this problem, only a handful of studies have analyzed the mechanisms at play.

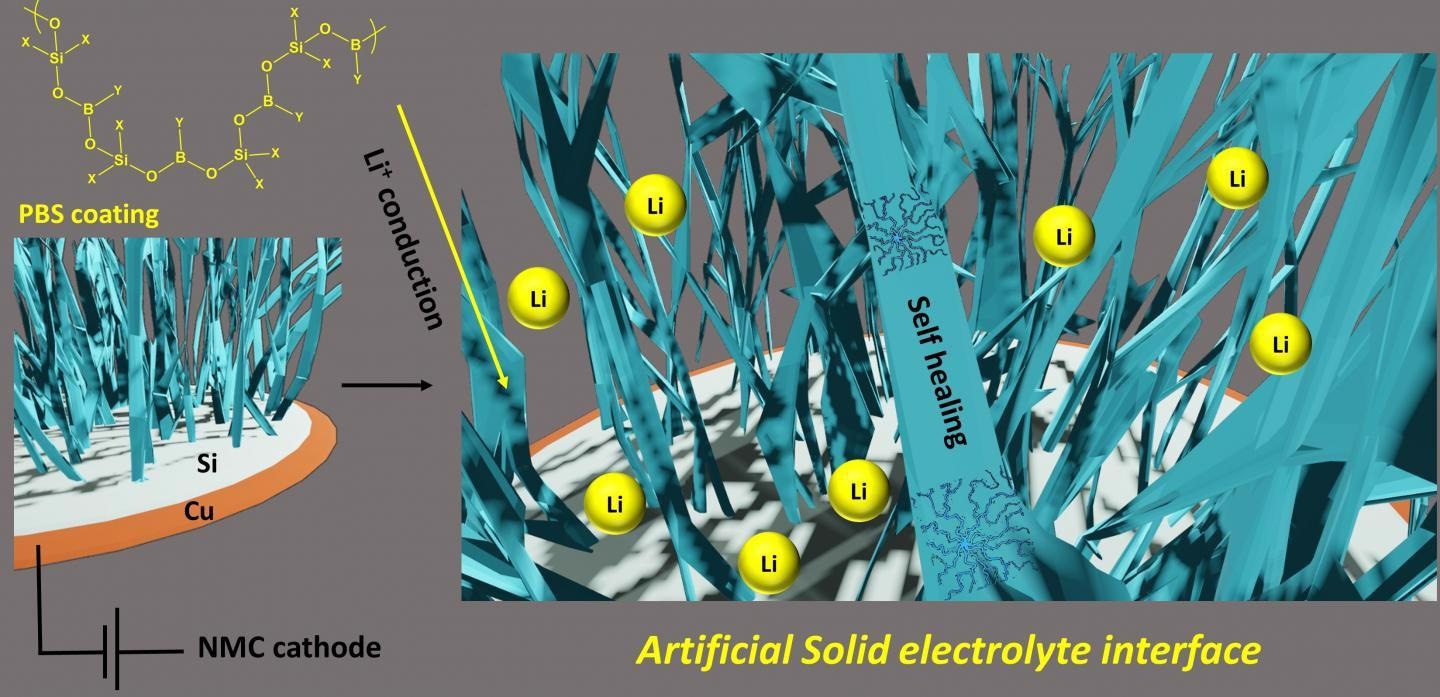

PBS serves as an artificial solid-electrolyte interface with good lithium ion conduction and self-healing abilities to automatically repair any cracks that form during operation. Image Credit: Noriyoshi Matsumi from JAIST.

PBS serves as an artificial solid-electrolyte interface with good lithium ion conduction and self-healing abilities to automatically repair any cracks that form during operation. Image Credit: Noriyoshi Matsumi from JAIST.

As part of a new study, researchers from Japan Advanced Institute of Science and Technology analyzed how a poly(borosiloxane) coating considerably stabilizes the capacity of silicon anodes, thus opening the door for better, more durable Li-ion batteries for renewable energy harvesting and electric cars.

From the time the concept of lithium-ion batteries (LIBs) was conceived, they have been constantly enhanced and adapted so that they match a wide range of applications, from storage units for renewable energy harvesters to electric cars and mobile devices.

In a majority of larger-scale applications (such as electric cars and renewable energy harvesters), the focus of studies on LIBs is to increase their voltage limits and capacity without increasing their overall size. To achieve this, the materials and components of the battery must be switched up.

Several researchers have proposed the use of silicon anodes rather the conventional graphite anodes. The anode is the part of the battery in which lithium ions are stored upon charging the battery, which subsequently flow through a medium known as electrolyte to the cathode on the other end when the charge of the battery is used up.

Although silicon is definitely a potential anode material that provides a nearly 10-fold increase in capacity for LIBs, it presents a range of challenges that must be overcome before commercializing silicone anodes.

In a new study published in ACS Applied Energy Materials journal, a research team from Japan Advanced Institute of Science and Technology (JAIST) mitigated the issues with silicon anodes by using a potential polymeric coating: poly(borosiloxane) (PBS). Headed by Professor Noriyoshi Matsumi, the study also involved Dr Sai Gourang Patnaik and Dr Tejkiran Pindi Jayakumar, who were completing a doctoral course at JAIST at the time.

Polymeric coatings can be a solution to one of the most critical drawbacks related to silicon anodes: the formation of a very large solid electrolyte interphase (SEI). The automatic formation of the SEI between the anode and the electrolyte is normally vital for the long-term performance of the battery.

But materials such as silicon tend to expand much with use, leading to continuous SEI formation and the depletion of the available electrolyte. This obviously affects the performance of the battery and results in a massive drop in capacity over time.

Polymeric coatings play a role exactly in this phase. They can avoid the excessive formation of SEI on silicon and form a stable, artificial SEI. Scientists had already noted the promising nature of PBS as a coating for silicon anodes, but earlier studies did not provide clear explanations for the underlying mechanisms, as explained by Prof. Matsumi:

There are very few reports on well-defined PBS-based polymers that offer a mechanistic origin for their application and their effects. Thus, we wanted to evaluate and shed light on their contribution to silicon anodes as a self-healing artificial interface that also prevents detrimental volume expansion.

Noriyoshi Matsumi, Professor, Japan Advanced Institute of Science and Technology

The short- and long-term performance of silicon anodes was compared with and without polymeric coatings with respect to capacity, stability and interfacial properties. This was performed using a series of electrochemical measurements and theoretical calculations, which enabled them to perceive how PBS helps to stabilize the silicon anode’s capacity.

When compared to anodes coated with poly(vinylidene fluoride) (a commercially used coating in LIBs) and bare silicon anodes, the self-healing characteristics of PBS and its reversible accommodation of lithium ions led to much more improved stability.

This is in part because of the ability of PBS to fill in any cracks that form in the SEI during operation. The capacity of the PBS-coated silicon anode was almost the same for more than 300 hundred cycles, in contrast to that of the other two anodes.

This study addressed the main problems related to silicon anodes, thus leading researchers to a new generation of LIBs with considerably higher durability and capacity. Prof. Matsumi was satisfied with the outcomes and remarked:

The widespread adoption of high-capacity LIBs will allow electric cars reach longer distances, drones become larger and renewable energy be stored more efficiently.

Noriyoshi Matsumi, Professor, Japan Advanced Institute of Science and Technology

Moreover, he notes that, within 10 years, LIBs might even be used as secondary energy sources in larger vehicles like trains, aircrafts and ships. Further studies could help achieve this.

Journal Reference

Patnaik, S. G., et al. (2021) Defined Poly(borosiloxane) as an Artificial Solid Electrolyte Interphase Layer for Thin-Film Silicon Anodes. ACS Applied Energy Materials. doi.org/10.1021/acsaem.0c02749.