Mar 3 2021

As far as green chemistry is concerned, identifying novel and lasting solutions to the material needs is one of the main targets.

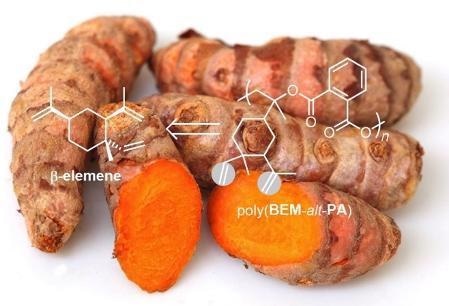

CIQ ACS kleij ginger root. Image Credit: ICIQ/Francesco Della Monica.

CIQ ACS kleij ginger root. Image Credit: ICIQ/Francesco Della Monica.

The countless plastics used by people in their everyday life, right from mattresses to food and cars, are mainly made from oil-based monomers that form the building blocks of polymers. Determining bio-based monomers for polymer synthesis is an appealing way to realize more lasting solutions in the area of materials development.

In a study published in the ACS Sustainable Chemistry & Engineering journal, scientists from the Kleij group describe a new method to make biobased polyesters with tunable properties. The team has been developing the multifunctional structure of the terpene β-elemene: three double bonds that exhibit unique reactivity, thus enabling a selective transformation of such bonds and hence tuning the functionalities in the polymer’s backbone.

This multi-functional terpene scaffold is rather unique and allows to fine-tune structural diversity and prospectively to modulate polymer and material properties.

Arjan Kleij, ICREA Professor and Group Leader, Institute of Chemical Research of Catalonia

The team collaborated with the company named Isobionics and made use of β-elemene obtained using a novel sugar-fermentation route. This process has been shown to be a potential path for the use of β-elemene as a raw material for polymerization.

Isobionic’s sugar-fermentation route completely changes the scale of β-elemene availability, which now can be used in polymer production.

Francesco Della Monica, Study First Author and Postdoctoral Researcher in Kleij Group, Institute of Chemical Research of Catalonia

Monica has been working in the European SUPREME project, as an MSCActions Individual Fellowship.

With the help of a ring-opening copolymerization reaction (ROCOP), the team integrated phthalic anhydride (a general monomer used to make polyesters) and β-elemene oxides and to prepare the biobased linear polymer poly(BEM-alt-PA) and its associated structure, crosslinked-poly(BED-alt-PA).

Such transformations were realized with catalytic systems (iron and aluminum aminotriphenolate complexes integrated with bis-(triphenylphosphine) iminium chloride) developed earlier by the team with non-critical, abundant elements for catalytic polymerization.

As soon as the polyester is made, there are two leftover double bonds from the actual terpene building block that can be simply and selectively addressed and functionalized, thereby enabling customization of the ultimate polyester.

These post-modification reactions on a biobased polymer are quite rare. Most of the biobased monomers that are available don't present functionalities.

Francesco Della Monica, Study First Author and Postdoctoral Researcher in Kleij Group, Institute of Chemical Research of Catalonia

The study serves as a foundation for more developments to β-elemene based polymers that enable customization of the properties of the final material (based on its use) via simple post-polymerization modifications.

The study does not deal with the material’s biodegradation, although Della Monica concluded that “depending on the final use, the ideal thing may not be biodegradation but to create a recyclable polymer: i.e., take a starting material, create the polymer, use it, recover it, and then degrade it in a controlled fashion and reuse that material. Now that we have the idea of a circular economy within grasp, we need circular processes.”

Journal Reference:

Monica, F D & Kleji, A W (2021) Synthesis and Characterization of Biobased Polyesters with Tunable Tg by ROCOP of Beta-Elemene Oxides and Phthalic Anhydride. ACS Sustainable Chemistry & Engineering. doi.org/10.1021/acssuschemeng.0c09189.