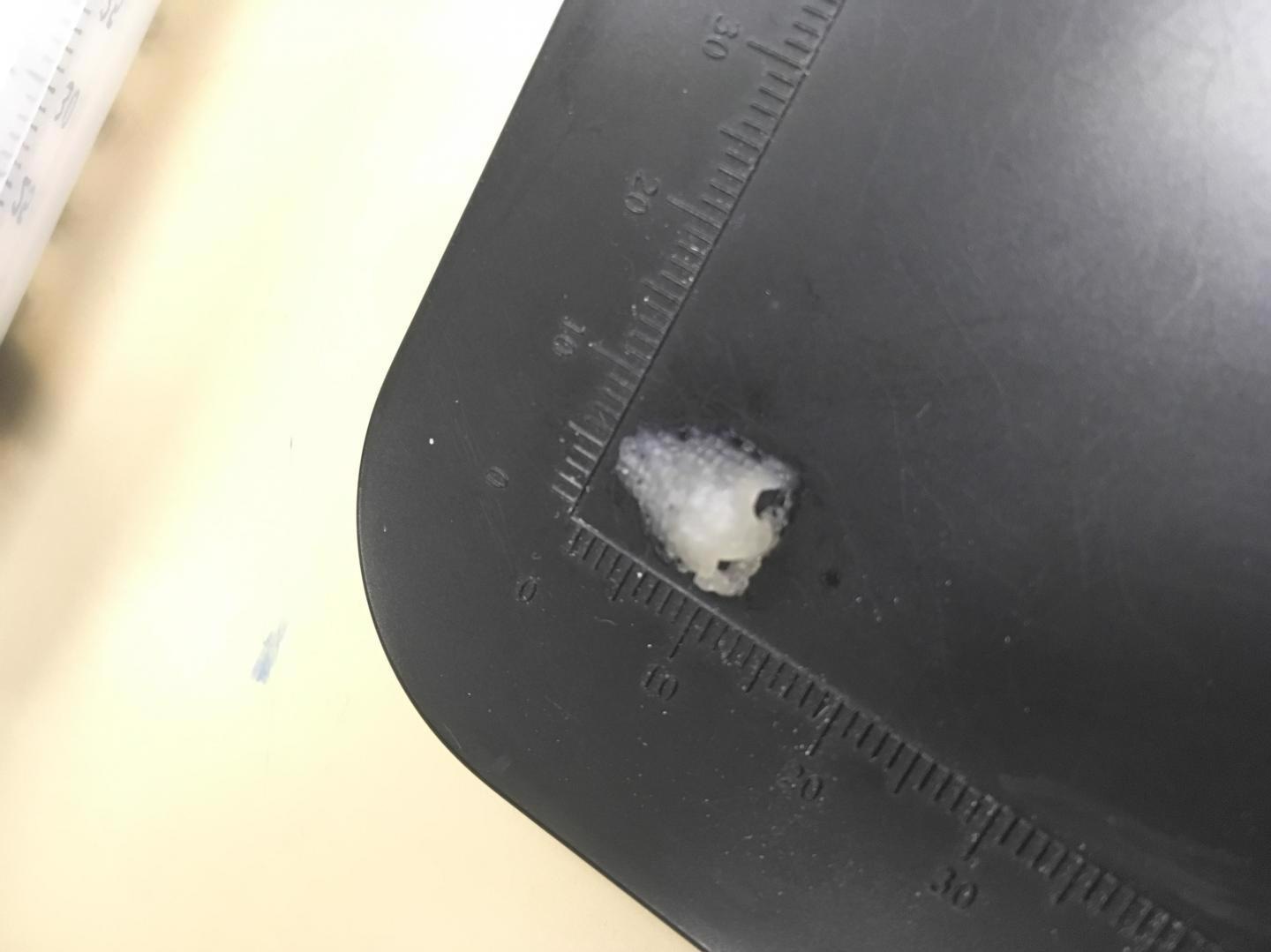

A 3D-printed scaffold of a nose. Image Credit: WSU

A 3D-printed scaffold of a nose. Image Credit: WSU

By mimicking the properties of human tissue, researchers have been able to create a scaffold for engineered tissues that could revolutionize medicine.

The field of tissue replacement has improved significantly over the past few years with the development of impressive 3D printing techniques that can be used to help patients recover from disease or injury. Scientists can now print complex, porous and personalized structures. The hope is that this can one day be extended to allow doctors and medical teams to print customized tissues in-situ for individual patients’ needs.

Unfortunately, this process isn’t yet perfect. Nature is incredibly complex and mimicking it is no easy task. One of the challenges facing bioengineers is that real tissues like skin grow on ‘scaffolds’ of tissues that have similar properties to themselves. This means that muscle cells successfully grow on scaffolds that feel like muscles, whilst skin ‘prefers’ to develop on skin-like scaffolds.

Professor Arda Gozen and his team could have hit upon a solution to this challenge, however. Together with a team of researchers including Joan Berry and George Berry, associate professors in the School of Mechanical and Materials Engineering, Washington State University (WSU), Gozen has developed a scaffolding material that can be adjusted to match the needs of the engineered tissues to be grown upon it.

The success of this method in manufacturing functional tissues relies heavily on how well the fabricated structures mimic the native tissues. If you want to grow cells and turn them into functional tissue, you need to match the mechanical environment of the native tissue.

Professor Arda Gozen, Associate Professor, School of Mechanical and Materials Engineering, Washington State University

The research conducted by the team, also including scientists from the University of Texas-San Antonio (USTA) and the Gene and Linda Voiland School of Chemical Engineering and Bioengineering (MSU), is documented in a new paper published in the journal Bioprinting¹.

Creating a Natural Tissue Scaffold

Of course, with continuing advancements in bioengineering, Gozen and his team aren’t the first to attempt to mimic natural scaffolds for the growth of engineered tissues.

Previous attempts to individualize scaffolds have frequently hinged on adding or removing support trusses to either stiffen or soften their structures. The problem with this approach has thus far been that it is too simple a method to tackle such a varied and complex problem as it lacks the ability to ‘fine tune’ the scaffold.

“We don’t have a lot of knobs to turn,” Gozen says, describing the lack of complexity in this approach. “You need more degrees of freedom — to create something softer or harder without changing the structure.”

To build a successful scaffold for engineered tissues, Gozen and his team developed a new biological material that can be dispensed from a nozzle and build layer-by-layer, creating a complex scaffold. Materials of this nature are known as bioinks and can be made from various substances, including collagen, gelatin methacryloyl and polyethene glycol.

The team’s bioink consisted of gelatin, gum Arabic, and sodium alginate, ingredients that may sound familiar as they are all common thickening agents found in processed foods.

This isn’t the only unique element of the process created by the team. The way the scaffold is put together is also quite special.

Wound Up for Fine Tuning

The process the team used to create their scaffold is analogous to the way in which common rope is made. The researchers used three distinct chemical processes to wind together strands of their ingredients into a scaffold.

The benefit of using three different processes is that they can be adjusted to give the resultant scaffold tunable properties — making it stiffer or softer depending on the requirements of the tissue to be grown on it — without changing it so much that cells won’t grow on it.

That gives you the capability of tuning the properties without changing the scaffold design and gives you an additional degree of freedom that we are seeking.

Professor Arda Gozen

The next step for the research will be to vary the composition of the bioink and the three materials that comprise it, thus perfecting both the printing process and the final product.

It’s early days for the project, but Gozen hopes that it could lead to doctors eventually being able to simply press a button on a 3D printer located in situ to create a custom skin, cartilage or muscle tissue for patients.

“You’re not assembling Legos here. It’s always about replicating nature that works with the body,” Gozen concludes. “You can make living structures, but they look nothing like the native tissue. Precision is key because there is no single mechanical property target for a single piece of tissue.”

References

1. Gozen. A., Amr. M., Dykes. I., et al, [2021], ‘3D printed, mechanically tunable, composite sodium alginate, gelatin and Gum Arabic (SA-GEL-GA) scaffolds,’ Bioprinting, [https://doi.org/10.1016/j.bprint.2021.e00133]

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.