Jun 8 2021

Flying cars, robot maids, and jet packs are all promises for the 21st century but instead, people received autonomous, mechanized vacuum cleaners.

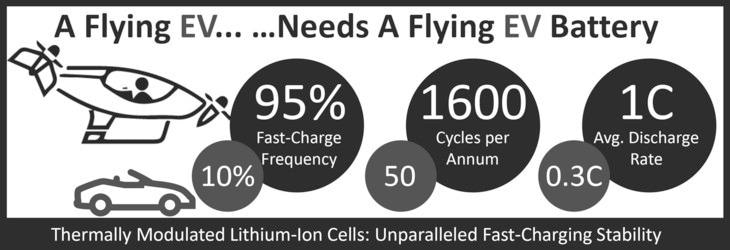

The automotive electric vehicle revolution is paving the way for urban air mobility, but people must not be naive in thinking that electric vehicle batteries will suffice for electric flight. The fast-charging requirements, 30x increase in energy throughput, and 3x power requirements demand a new generation of batteries. Image Credit: Eric Rountree, EC Power.

Now, a research team from Penn State is investigating the needs for electric vertical takeoff and landing (eVTOL) vehicles and developing and testing promising battery power sources.

I think flying cars have the potential to eliminate a lot of time and increase productivity and open the sky corridors to transportation. But electric vertical takeoff and landing vehicles are very challenging technology for the batteries.

Chao-Yang Wang, Holder of the William E. Diefender, Chair of Mechanical Engineering and Director of Electrochemical Engine Center, Penn State

The researchers have defined the technical requirements for flying car batteries and have reported on a prototype battery that was recently published in the Joule journal on June 7th, 2021.

Batteries for flying cars need very high energy density so that you can stay in the air. And they also need very high power during take-off and landing. It requires a lot of power to go vertically up and down.

Chao-Yang Wang, Holder of the William E. Diefender, Chair of Mechanical Engineering and Director of Electrochemical Engine Center, Penn State

Wang observed that the batteries will also need to be quickly recharged so that high revenue could be acheived during peak hours. According to Wang, such vehicles have frequent take-offs and landings and tend to recharge rapidly and frequently.

“Commercially, I would expect these vehicles to make 15 trips, twice a day during rush hour to justify the cost of the vehicles. The first use will probably be from a city to an airport carrying three to four people about 50 miles,” added Wang.

Weight is another consideration for such batteries because the vehicle will need to lift and land the batteries. After the eVTOL takes off, the average speed would be 100 miles per hour, while it would be an average speed of 200 miles per hour on long trips, according to Wang.

At the experimental level, the team tested a couple of energy-dense lithium-ion batteries that can recharge with sufficient energy for a 50-mile eVTOL trip in 5 to 10 minutes. Such batteries could sustain more than 2,000 fast charges over their lifetime.

Wang and his research group applied the technology that they have been working on for electric vehicle batteries. The key is to heat the battery to enable quick charging while making sure that lithium spikes are not formed which otherwise may impair the battery and can be dangerous. But it turns out that that heating the battery also allows rapid discharge of the energy confined in the battery to enable both take-offs and landings.

The researchers heated the batteries by integrating a nickel foil that brings the battery quickly to 140 °F.

Under normal circumstances, the three attributes necessary for an eVTOL battery work against each other. High energy density reduces fast charging and fast charging usually reduces the number of possible recharge cycles. But we are able to do all three in a single battery.

Chao-Yang Wang, Holder of the William E. Diefender Chair of Mechanical Engineering and Director of Electrochemical Engine Center, Penn State

One special feature of flying cars is that the batteries should invariably retain some charge. For instance, unlike cellphone batteries that work best when completely discharged and recharged, a flying car battery can never be allowed to fully discharge in the atmosphere because power is required to remain in the air and to land. There should always be a margin of safety in the case of a flying car battery.

When a battery is empty, internal resistance to charging tends to be low, but when the remaining charge becomes higher, it becomes harder to push a larger amount of energy into the battery. Normally, recharging slows down as the battery fills, but if the battery is heated, recharging can range from 5 to 10 minutes.

“I hope that the work we have done in this paper will give people a solid idea that we don't need another 20 years to finally get these vehicles. I believe we have demonstrated that the eVTOL is commercially viable,” added Wang.

The study also involved Xiao-Guang Yang and Shanhai Ge, both assistant research professors in mechanical engineering, and Teng Liu, a doctoral student in mechanical engineering, all from Penn State; and Eric Roundtree from EC Power, State College, Pennsylvania.

This study was financially supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy, the U.S. Air Force Small Business Technology Transfer program, and the William E. Diefenderfer Endowment.

Journal Reference:

Yang, X-G., et al. (2021) Challenges and key requirements of batteries for electric vertical takeoff and landing aircraft. Joule. doi.org/10.1016/j.joule.2021.05.001.