Jun 25 2021

New research from Tufts University, the University College London (UCL), Cambridge University and the University of California at Santa Barbara has shown that a catalyst can definitely be an agent of change.

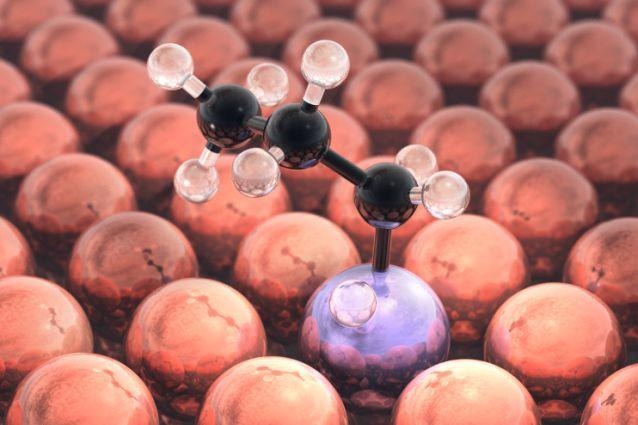

Artistic rendering of the propane dehydrogenation process taking place on the novel single Rhodium atom alloy catalyst, as predicted by theory. Image Credit: Charles Sykes and Michail Stamatakis.

Artistic rendering of the propane dehydrogenation process taking place on the novel single Rhodium atom alloy catalyst, as predicted by theory. Image Credit: Charles Sykes and Michail Stamatakis.

Using quantum chemical simulations run on supercomputers, the researchers predicted a new catalyst design and also the interactions of this design with specific chemicals. They also showed, in practice, the ability of this architecture to create propylene — presently in short supply — which is crucially required for producing fabrics, plastics and other kinds of chemicals. The study was recently published in the Science journal.

Such improvements may lead to “greener,” highly efficient chemistry with a lower carbon footprint.

The demand for propylene is around 100 million metric tons (which is worth around $200 billion) per year, but sufficient propylene is not available at this time to fulfill the rising demand. Next to ethylene and sulfuric acid, the production of propylene involves the third-largest conversion process in the chemical sector by scale.

Steam cracking is the most common technique for producing ethylene and propylene. This method, however, has a limited yield of 85% and is also one of the most energy-intensive procedures in the chemical sector. The standard feedstocks used for producing propylene are actually by-products obtained from oil and gas operations, but the migration to shale gas has restricted its production.

The general catalysts used for producing propylene from propane found in shale gas are composed of combinations of metals. These metals can have a complex, random structure at the atomic level.

Moreover, the reactive atoms are generally combined together in several different ways. This makes it hard to develop novel catalysts for reactions based on the underlying calculations of the potential interaction of chemicals with the surface of the catalyst.

On the other hand, single-atom alloy catalysts identified at Tufts University and initially reported in the Science journal in 2012 can distribute single-reactive metal atoms in a more inert surface of the catalyst, at a density of around 1 reactive atom to 100 inert atoms.

This allows a well-defined interaction between the chemical being processed and a single catalytic atom, without being compounded by superfluous interactions with other nearby reactive metals.

Reactions that are catalyzed by single-atom alloys are efficient and clean, and as shown in the new research work, they can now be predicted by theoretical techniques.

We took a new approach to the problem by using first principles calculations run on supercomputers with our collaborators at University College London and Cambridge University, which enabled us to predict what the best catalyst would be for converting propane into propylene.

Charles Sykes, Study Corresponding Author and John Wade Professor, Department of Chemistry, Tufts University College London

Such calculations, which resulted in predicting the reactivity on the surface of the catalyst, were validated by atomic-scale imaging as well as reactions run on model catalysts. The team subsequently produced single-atom alloy nanoparticle catalysts and assessed them under industrially pertinent conditions.

In this specific application, however, rhodium (Rh) atoms scattered on the surface of copper (Cu) worked optimally to dehydrogenate propane to create propylene.

Improvement of commonly used heterogeneous catalysts has mostly been a trial-and-error process. The single-atom catalysts allow us to calculate from first principles how molecules and atoms interact with each other at the catalytic surface, thereby predicting reaction outcomes.

Michail Stamatakis, Study Co-Corresponding Author and Associate Professor of Chemical Engineering, University College London

Stamatakis continued, “In this case, we predicted rhodium would be very effective at pulling hydrogens off molecules like methane and propane — a prediction that ran counter to common wisdom but nevertheless turned out to be incredibly successful when put into practice. We now have a new method for the rational design of catalysts.”

In this analysis, the single-atom Rh catalyst was found to be extremely efficient, with complete selective production of propylene, when compared to 90% for existing industrial propylene production catalysts, in which selectivity refers to the number of reactions at the catalytic surface that result in the preferred product.

That level of efficiency could lead to large cost savings and millions of tons of carbon dioxide not being emitted into the atmosphere if it’s adopted by industry.

Charles Sykes, Study Corresponding Author and John Wade Professor, Department of Chemistry, Tufts University College London

In addition to being more efficient, the single-atom alloy catalysts also run reactions under lower temperatures and milder conditions, and thus involved less energy to run than traditional catalysts. Single-atom alloy catalysts can also be more economical to produce, needing just a small amount of precious metals, such as rhodium or platinum, which can be cost-prohibitive.

For instance, the current cost of rhodium is about $22,000 per ounce, whereas copper, which contains 99% of the catalyst, costs only 30 cents an ounce. The novel rhodium/copper single-atom alloy catalysts are also impervious to coking — a pervasive concern in industrial catalytic reactions where high-carbon content intermediates — basically, soot — builds up on the catalyst surface and starts to inhibit the required reactions. Such enhancements serve as a recipe for “greener” chemistry with a lower carbon footprint.

“This work further demonstrates the great potential of single-atom alloy catalysts for addressing inefficiencies in the catalyst industry, which in turn has very large economic and environmental payoffs,” concluded Sykes.

Journal Reference:

Hannagan, R. T., et al. (2021) First-principles design of a single-atom–alloy propane dehydrogenation catalyst. Science. doi.org/10.1126/science.abg8389.