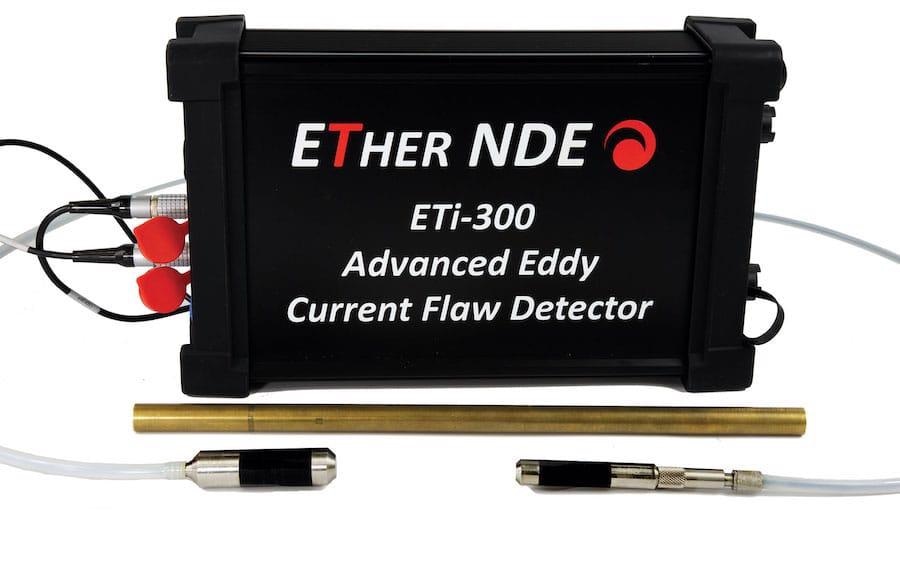

ETher NDE brings to market an innovative end-to-end Tube inspection Solution, with the new ETi-300 advanced flaw detector, boosted by two new software packages.

Image Credit: ETher NDE

Realising that the inspection process is more than just recording data the ETi-300 was conceived to be part of an end-to-end solution, developed to improve inspection workflow. Our new ETherMap analysis software has been developed to partner the inspector on-site for data capture and analysis and the new TMR_ET Reporting software is now being offered to deliver super-fast tube mapping, plus rapid and accurate reporting.

Eddy Current testing has long been acknowledged as the fastest, most efficient and effective inspection method to inspect the large quantity of non-ferrous tubes present in a typical heat exchanger. The ETi-300 is the new advanced eddy current instrument for inspecting non-ferrous tubing from the inner diameter (ID), developed by ETher NDE to perform in the most demanding of environments whilst delivering outstanding inspection results and reporting functionality.

The ETi-300 instrument and our suite of analysis and reporting software are built for non-ferrous heat exchanger and condenser inspection applications within Power Generation, Transportation, Petrochemical and Oil and Gas industries.

The intrinsic rugged design, high impact resistant enclosures, meeting IP66, with an excellent battery life of up to 15 hours demonstrates that the new headless ETi-300 has been designed with the end task and hazardous environment in mind. Our hardware is well known for having the very best signal to noise capability, the widest balance range and best low frequency performance. The ETi-300's extremely wide test frequency range 10Hz-12.8 MHz gives maximum flexibility in designing a test configuration no matter what the material or wall thickness. These features absolutely deliver improved defect detection and together with the constant sample rate of 16,000 samples per second, across all channels, ensures a very high maximum probe pull back speed.

ETherMap is not only the data analysis tool but also the main user interface to the head-less (no screen) instrument. This versatile software was developed to be directly connected to our latest instruments where it can control and receive live inspection data in the field, or work with previously recorded data. EtherMap is an intuitive user interface for the ETi 300 operator, capable of processing and analysing data on its own or as an integral part of our end-to-end offering with TMR-ET. When integrated with TMR-ET the user can go all the way from Tube Map design, to inspection and analysis, through to report generation .

In order to offer the best user experience when it comes to tube map design and report generation Ether NDE have teamed up with Talcyon Pte Ltd, to deliver advanced Tube Mapping Software (TMR-ET) which is second to none in its features and ease-of-use. TMR-ET is a solution designed specifically to produce an accurate layout and labelling of tubes on a tube sheet. Collectively needed for tube inspection and maintenance reporting, TMS offers user-friendly features that allow companies to carry out their reporting faster and more efficiently. Maps can be created from schematics or photographs quickly and easily.

TMR-T Reporting gives the operator rapid reporting capability, managing data gathered from inspections, presenting inspection data in easy-to-read formats. Reports are generated using a simple user interface and templates, whilst fully-customisable reporting and output is easily configurable to match the needs of the operators and asset owners. Graphs, charts and 2D visualisations of tubes and their defects are all available through your personally “constructed dashboard”.

At ETher NDE we pride ourselves on offering our customers the very best in product design, manufacture and customer care whether it is via our standard eddy current equipment range or our bespoke product solutions working with our customers and partners. The ETi-300 will come with a standard 2 year warranty which through ETherCover Level 1 can be extended to 5 years. This will include free of charge annual re-calibrations and “health checks” from the end of year 1, two free battery swaps within the 5 year period and free of charge software upgrades, guaranteeing our customers peace of mind and lowest-cost lifetime ownership.

About ETher NDE

We are a dedicated manufacturer of Eddy Current (ECT) non-destructive testing (NDT) equipment, probes and accessories and the 'go to' company for all your Eddy Current (EC) NDT Solutions. ETher NDE was founded on three core principles and to this day they are still what we operate in line with everyday. They are firstly the ability to speak to someone who understands our product, the industry and your applications; secondly industry-leading delivery times on equipment and probes and the ability to respond to your challenges and thirdly that our products are second to none in both performance and quality. We are proud that as a company we operate to these core principles continuously and that we are true to the main reason the company was founded; to offer Eddy Current NDT Solutions to the industry backed up by a wealth of knowledge and sealed with great customer service from real people who care and are passionate about what they do.