Super-thin carbon molecular sieve (CMS) membranes may not be ideal for isolating industrially important chemical mixtures. However, KAUST researchers note that if the right CMS film thickness is ensured, it could power more energy-efficient purification of chemical products.

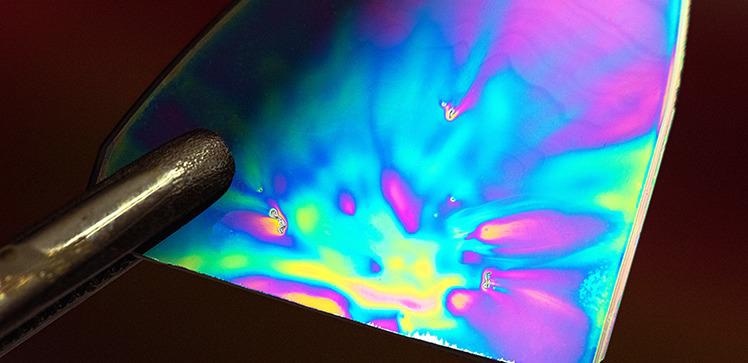

Carbon molecular sieve membranes are widely used in industrial processes to separate chemicals and gases, but such processes are energy-intensive. Image Credit: Anastasia Serin, King Abdullah University of Science and Technology.

Carbon molecular sieve membranes are widely used in industrial processes to separate chemicals and gases, but such processes are energy-intensive. Image Credit: Anastasia Serin, King Abdullah University of Science and Technology.

CMS membranes are capable of purifying mixtures of liquids or gases by allowing only specific molecules to pass through their sub-nanometer-sized pores. At present, the chemical industry predominantly employs heat-based processes, like distillation, to separate product mixtures but these processes consume about 10% of global energy output.

This situation is highly unsustainable. We believe that a good portion of these energy-intensive separations could be replaced by much more environmentally friendly membrane separations.

Wojciech Ogieglo, Research Scientist, King Abdullah University of Science and Technology

CMS membranes are formed by depositing a layer of carbon-rich polymers onto a suitable platform, following which heat is applied to convert the polymer into a microporous CMS film.

CMS materials display by far the best performance for a wide variety of highly energy-intensive membrane-based gas separation applications.

Ingo Pinnau, Group Leader, King Abdullah University of Science and Technology

“These materials are also particularly chemically robust. They are promising for situations such as plastics production or greenhouse gas capture because they perform reliably even in very harsh chemical environments and at high temperatures,” stated Ogieglo.

One element of CMS membrane research is to improve the CMS film thickness to reduce the energy needed to isolate a chemical mixture. “Intuitively, one could think that the thinner the membrane, the better,” stated Ogieglo.

A thinner CMS layer would be predicted to present the least transport resistance to molecules that pass through its pores. Yet, the researchers observed that when they developed sub-50 nm CMS films, the CMS layer was highly compact and exhibited low microporosity.

“Such extremely thin films turn out to pose much more transport resistance than expected,” added Ogieglo. The team revealed that thicker 300-nm CMS films exhibit remarkably higher microporosity.

We believe that there must be a sweet spot in the thickness range — not too thin, not too thick — where the membrane performance is optimal. We are currently trying to find out where this sweet spot lies for different types of membrane materials.

Wojciech Ogieglo, Research Scientist, King Abdullah University of Science and Technology

“The results will feed into the team’s wider efforts to create scalable, industry-ready CMS separation membranes. We are currently scaling up the production of CMS composite membranes to test their performance and long-term stability in membrane modules,” concluded Pinnau.

Sweet spot for membrane thickness offers sustainable separations

KAUST scientists are developing special membranes to make industrial chemical and solid separations more environmentally friendly. Video Credit: Anastasia Serin, King Abdullah University of Science and Technology.

Journal Reference:

Ogieglo, W., et al. (2021) Nano-Confinement Effects on Structural Development and Organic Solvent-Induced Swelling of Ultrathin Carbon Molecular Sieve Films. Applied Materials and Interfaces. doi.org/10.1021/acsami.1c03392.