Researchers have been attempting to make reliable lithium-metal batteries for a long time. Such high-performance storage cells contain 50% more energy compared to their prolific, lithium-ion equivalents.

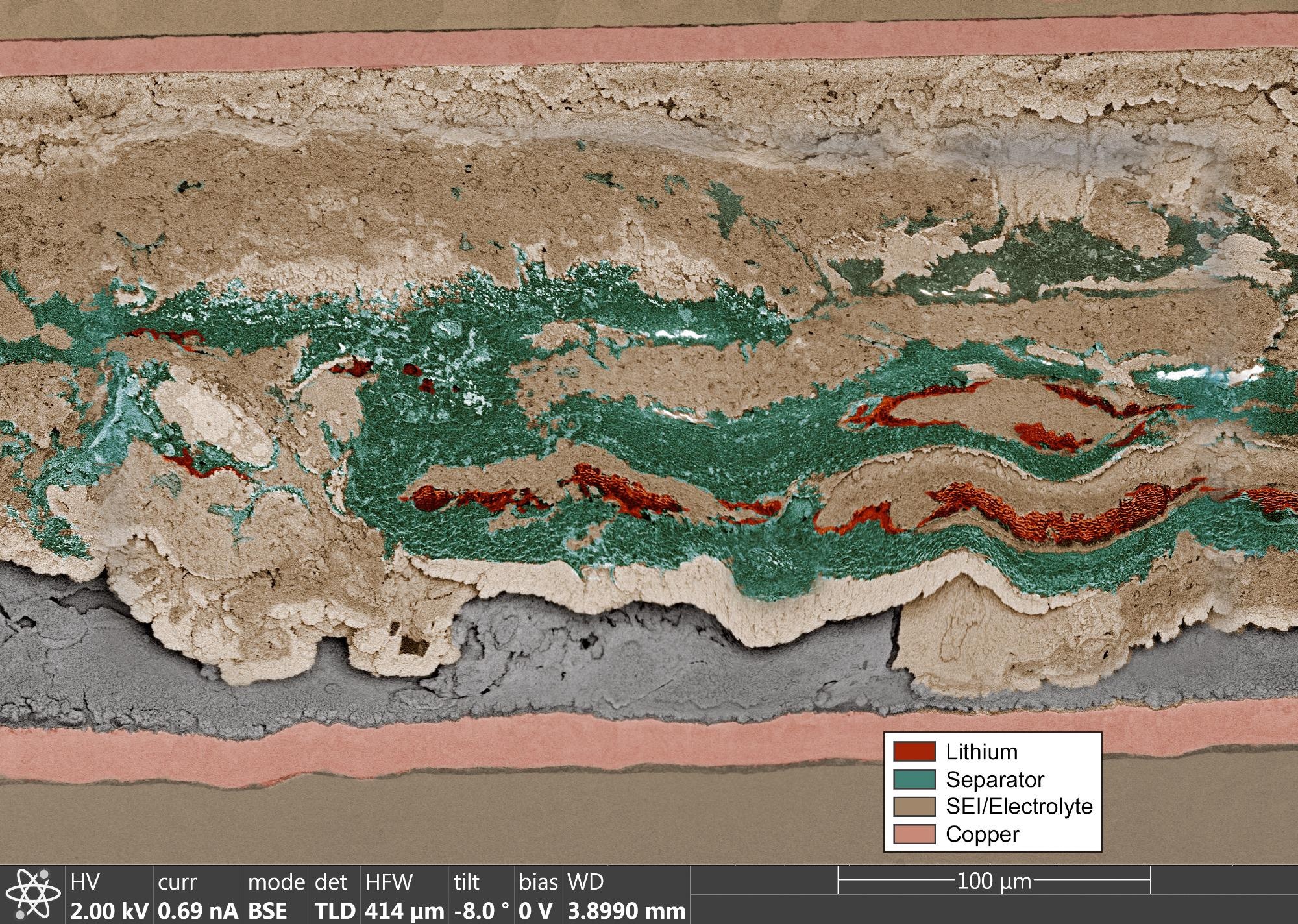

In this new, false-color image of a lithium-metal test battery produced by Sandia National Laboratories, high-rate charging and recharging red lithium metal greatly distorts the green separator, creating tan reaction byproducts, to the surprise of scientists. Image Credit: Katie Jungjohann.

In this new, false-color image of a lithium-metal test battery produced by Sandia National Laboratories, high-rate charging and recharging red lithium metal greatly distorts the green separator, creating tan reaction byproducts, to the surprise of scientists. Image Credit: Katie Jungjohann.

However, they present greater failure rates and safety issues like explosions and fires, thereby disabling commercialization measures.

Although scientists have postulated the reason behind the failure of the devices, direct evidence has been relatively less.

The first nanoscale images that have ever been taken within intact, lithium-metal coin batteries (also known as watch batteries or button cells) challenge the existing theories and could help make high-performance batteries in the future, for example, making electric vehicles, safer, longer-lasting and stronger.

We’re learning that we should be using separator materials tuned for lithium metal.

Katie Harrison, Battery Scientist, Sandia National Laboratories

Harrison guides the Sandia team in enhancing the performance of lithium-metal batteries.

The images were recently reported by the Sandia researchers, in collaboration with Thermo Fisher Scientific Inc., the University of Oregon, and Lawrence Berkeley National Laboratory, in the ACS Energy Letters journal. The study was financially supported by Sandia’s Laboratory Directed Research and Development program and the Department of Energy.

Internal Byproduct Builds Up, Kills Batteries

Lithium coin cells were repeatedly charged and discharged by the researchers with the same high-intensity electric current required by electric vehicles to charge. Certain cells underwent a few cycles, while others went through over a hundred cycles. The cells were then dispatched for analysis to Thermo Fisher Scientific in Hillsboro, Oregon.

A review of the images of the inner sides of the batteries was predicted to show needle-shaped deposits of lithium covering the battery. A majority of the battery researchers consider that a lithium spike occurs following repetitive cycling and it strikes through a plastic separator between the anode and the cathode, thereby developing a bridge that results in a short.

However, lithium is a soft metal and, therefore, researchers are not yet clear on how it could get across the separator.

A surprising second culprit was identified by Harrison’s team. A tough buildup developed as a byproduct of the internal chemical reactions of the battery. Whenever the battery was recharged, the byproduct, known as solid electrolyte interphase, accumulated.

It capped the lithium and formed holes in the separator, making openings for metal deposits to spread and end up in a short. Collectively, the lithium deposits and the byproduct were much more harmful compared to what was previously thought, acting more like a snowplow and less like a needle.

The separator is completely shredded.

Katie Harrison, Battery Scientist, Sandia National Laboratories

This mechanism has only been noted under quick charging rates required for electric vehicle technologies, but not under slower charging rates, added Harrison.

The Sandia researchers have a plan of altering separator materials, and therefore, Harrison states that additional research will also be required to decrease the development of byproducts.

Scientists Pair Lasers with Cryogenics to Take “Cool” Images

Finding the reason behind the death of a coin battery is hard and the problem arises from its stainless-steel casing. The metal shell restricts what diagnostics, such as X-rays, can view from the outer part, while eliminating parts of the cell for analysis rips apart the layers of the battery, and disfigures whatever proof might be present inside.

We have different tools that can study different components of a battery, but really we haven’t had a tool that can resolve everything in one image.

Katie Jungjohann, Nanoscale Imaging Scientist, Center for Integrated Nanotechnologies, Sandia National Laboratories

The center is a user facility that is collaboratively run by Sandia and Los Alamos national laboratories.

Jungjohann and her colleagues used a microscope that consists of a laser to mill through the outer casing of a battery. The microscope was coupled with a sample holder that holds the liquid electrolyte of the cell frozen at temperatures between −148 °F and −184 °F (or −100 °C and −120 °C, respectively).

The laser makes a sufficient opening for a narrow electron beam to penetrate and bounce back onto a detector, thereby offering a high-resolution image of the internal cross-section of the battery with all the available details to differentiate the various materials.

The actual demonstration instrument, which was the only such tool in the United States at the time, was developed and is still available at a Thermo Fisher Scientific laboratory in Oregon. Currently, an updated duplicate is available at Sandia. The tool will be utilized extensively throughout Sandia to help resolve several materials and failure-analysis issues.

Jungjohann concluded, “This is what battery researchers have always wanted to see.”

Journal Reference:

Jungjohann, K. L., et al. (2021) Cryogenic Laser Ablation Reveals Short-Circuit Mechanism in Lithium Metal Batteries. ACS Energy Letters. doi.org/10.1021/acsenergylett.1c00509.