The addition of calcium and lead to an industrial catalyst significantly improves its potential to promote the production of propylene at extreme temperatures, which makes it firm and active for around a month.

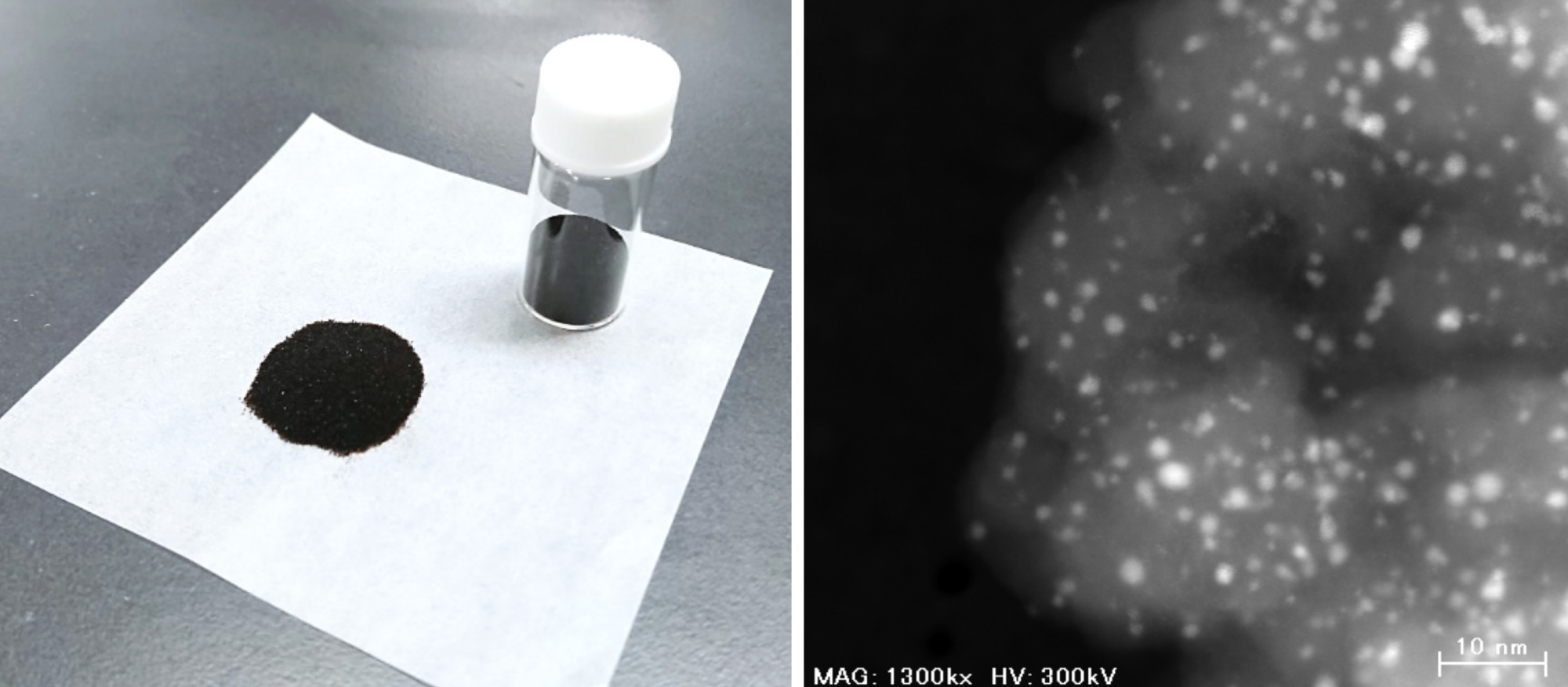

The newly developed catalyst in powder form (left) and under a transmission electron microscope (right). Image Credit: Shinya Furukawa.

The newly developed catalyst in powder form (left) and under a transmission electron microscope (right). Image Credit: Shinya Furukawa.

Researchers from Hokkaido University have developed a catalyst for propylene production that is quite stable, even at 600 °C. Their design concept and results were reported in the journal Angewandte Chemie International Edition.

Propylene is considered to be the most valuable raw material and building block for a wide range of products, such as electronics, plastics and textiles. It was originally synthesized as a byproduct of disintegrating saturated hydrocarbons in a process known as steam cracking. Yet, this process does not offer the quantities required by industry anymore.

In recent years, the industry has been producing propylene from shale gas. Shale gas includes a huge amount of methane, propane and ethane in smaller quantities. It is viable to produce propylene from propane by removing two hydrogen atoms from it via a process called propane dehydrogenation.

This process takes place at very high temperatures of nearly 600 °C. Platinum has been extensively utilized as a catalyst in propane dehydrogenation, as it promotes the removal of hydrogen atoms from carbon. However, it is quickly deactivated by side reactions that take place at high temperatures.

A group of researchers at Hokkaido University’s Institute for Catalysis was headed by Shinya Furukawa, an associate professor, to enhance existing platinum catalysts.

In particular, they worked with a platinum catalyst alloyed with gallium, which is one of several inactive metals that can help decrease the unnecessary side reactions that tend to deactivate the catalyst at high temperatures by isolating the platinum atoms from each other. Yet, the separation of gallium from platinum atoms is not complete.

Furukawa and his collaborators' introduced lead atoms to platinum-gallium nanoparticles placed on a silicon oxide base. The lead atoms were fixed to the surface of the nanoparticles in the place where three platinum atoms occurred jointly. This stops the side reactions that take place at the sites of the aggregated platinum atoms, thereby leaving single atoms to perform the dehydrogenation work.

The researchers enhanced the catalyst by depositing calcium ions on its silicon oxide base. The calcium ions contribute electrons to the platinum-gallium nanoparticles, which helps enhance their stability.

Our ‘doubly decorated’ platinum-gallium catalyst had a significantly superior stability, of one month at 600°C, compared to other reported propane dehydrogenation catalysts which are deactivated within several days.

Shinya Furukawa, Study Corresponding Author and Associate Professor, Institute for Catalysis Hokkaido University

The scientists experimented with additives and bases other than silicon oxide and calcium ions but none exhibited excellent catalytic stability and ability of the doubly decorated platinum gallium catalyst.

Our catalyst design concept paves the way for enhancing the catalytic performance of intermetallics in saturated hydrocarbon dehydrogenation.

Shinya Furukawa, Study Corresponding Author and Associate Professor, Institute for Catalysis Hokkaido University

This study was financially supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI (G17H01341, 17H04965); the Ministry of Education, Culture, Sports, Science and Technology Japan (MEXT) project Element Strategy Initiative (JPMXP0112101003), Japan Science and Technology Agency (JST), Core Research for Evolutional Science and Technology (CREST; JPMJCR17J3) and Precursory Research for Embryonic Science and Technology (PRESTO; JPMJPR19T7).

The XAFS analysis was executed with the approval of the Japan Synchrotron Radiation Research Institute (JASRI; 2020A1255, 2020A1609, 2021A1541).

Journal Reference:

Nakaya, Y., et al. (2021) Doubly Decorated Platinum–Gallium Intermetallics as Stable Catalysts for Propane Dehydrogenation. Angewandte Chemie International Edition. doi.org/10.1002/anie.202107210.