Carbon dioxide is regarded as one of the primary contributors to climate change, which implies that CO2 emission needs to be controlled in the future. Scientists from Fraunhofer are projecting a potential method to reduce these emissions.

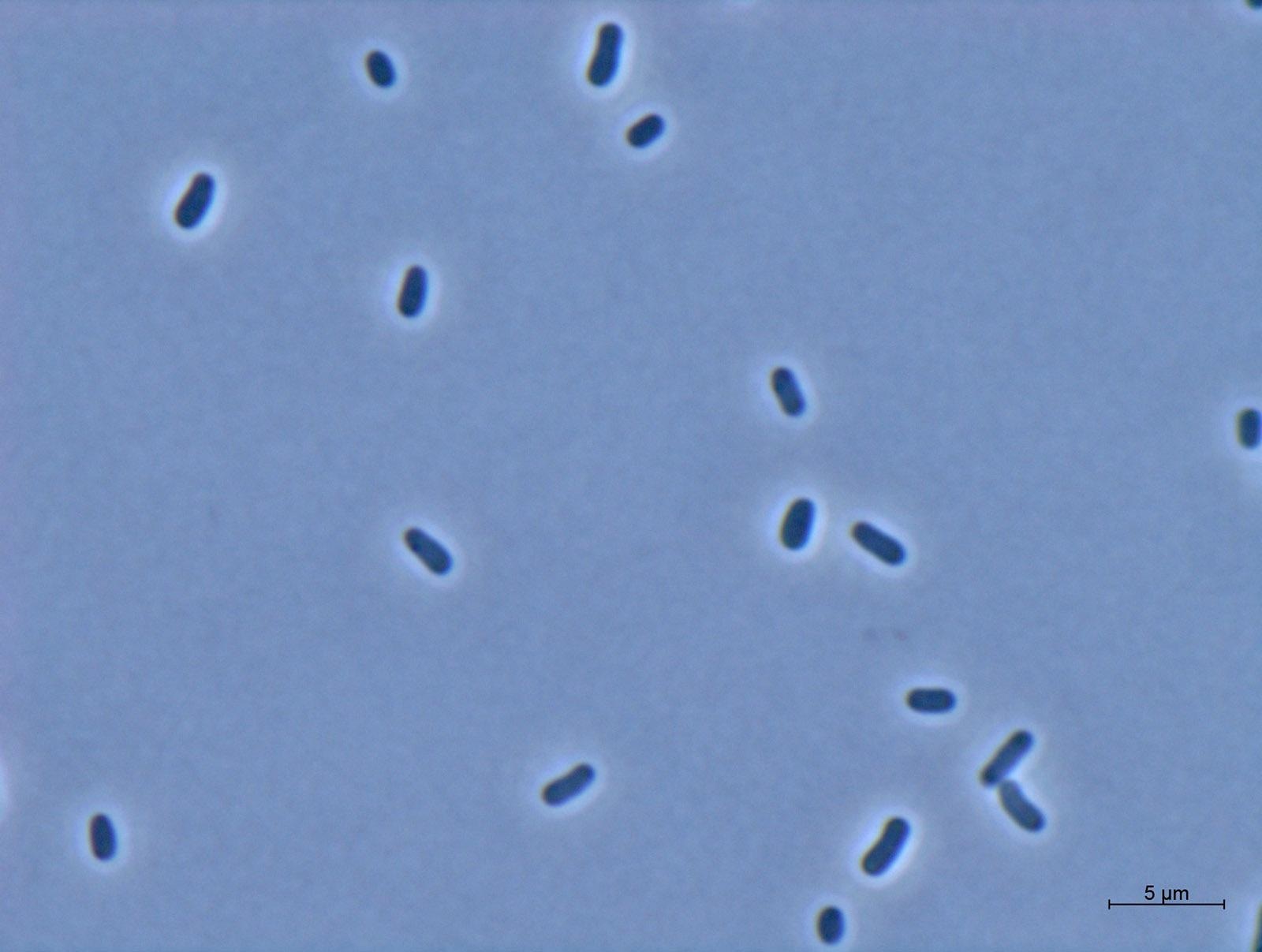

Light micrograph of cells of the gram-negative bacterium Methylorubrum extorquens AM1. Image Credit: Fraunhofer IGB.

Light micrograph of cells of the gram-negative bacterium Methylorubrum extorquens AM1. Image Credit: Fraunhofer IGB.

They employed greenhouse gas as a raw material for producing plastics. To perform this, they initially produced formic acid and methanol from CO2, which were later converted into building blocks for polymers and similar materials through microorganisms.

When fossil-based raw materials are burned, CO2 is emitted into the atmosphere. Until now, CO2 concentration in the Earth’s atmosphere has already increased to nearly 400 parts per million (ppm), which equals 0.04%. This level was valued at 280 ppm until the mid-19th century.

The elevated level of carbon dioxide has a notable effect on the climate. From January 1st, 2021, CO2 emissions obtained from the combustion of fossil fuels have added to carbon pricing, implying that the manufacturers have to pay for their CO2 emissions. Consequently, this encouraged a greater number of companies to look for fresh solutions.

Techniques on cost reduction associated with CO2 emission pricing and CO2 emission reduction through the bio-intelligent process were under focus.

Catalytic Chemistry and Biotechnology — a Winning Combination

At present, researchers are working on techniques to overcome this issue in the EVOBIO and ShaPID projects at the Fraunhofer Institute of Interfacial Engineering and Biotechnology IGB. The project is a collaborative work involving several Fraunhofer Institutes.

We use the CO2 as a raw material. We’re pursuing two approaches: First, heterogeneous chemical catalysis, by which we convert the CO2 with a catalyst to methanol. Second, electrochemistry, by which we produce formic acid from CO2.

Dr Jonathan Fabarius, Senior Scientist Biocatalysts, Fraunhofer IGB

Yet, this unique aspect is not only relevant to CO2-based methanol and formic acid production but also relies on the combination with biotechnology, particularly with fermentations induced by microorganisms.

In simple words, the scientists initially use the waste product CO2, which is detrimental to the climate, to generate formic acid and methanol. These components are further used to “feed” microorganisms that again produce additional products from them.

For example, these kinds of organic acids are utilized to build blocks for polymers, which is a method to generate plastics based on CO2. This technique can also be employed to form amino acids, such as animal feed or food supplements.

According to Fabarius, the novel method provides an array of advantages.

We can create entirely new products, and also improve the CO2 footprint of traditional products.

Dr Jonathan Fabarius, Senior Scientist Biocatalysts, Fraunhofer IGB

Traditional chemical processes need a high amount of energy and toxic solvents at times, but the new technology is capable of producing products with microorganisms under mild and more energy-efficient environments. Indeed, the microbes tend to grow in more eco-friendly aqueous solutions.

Metabolic Engineering Makes it Possible

The researchers employed both native methylotrophic bacteria that are capable of naturally metabolizing methanol and yeasts that cannot metabolize methanol. They are also keen to observe the new interesting organisms and assess them for suitability as “cell factories.”

However, the way these microorganisms generate the products and the way that they can be influenced to produce a certain product is being questioned.

In principle, we use the microorganism’s metabolism to control product manufacture. To do so, we introduce genes into the microbes that provide the blueprint for certain enzymes. This is also known as metabolic engineering.

Dr Jonathan Fabarius, Senior Scientist, Biocatalysts, Fraunhofer IGB

The enzymes that are then produced in the microorganism tend to catalyze the production of a particular product in turn. On the other hand, the researchers shut down genes that could negatively impact this production.

“By varying the genes that are introduced, we can produce a wide range of products,” states Fabarius.

The team is looking forward to the complete production chain, beginning with the microorganisms, followed by the gene modification and increasing the production. A few production processes are still on the laboratory table, but production of other products has started in bioreactors with a capacity of 10 L.

According to Fabarius, industrial usage of such processes may require implementation in the medium to long term. This could span for 10 years, as commented by Fabarius. However, pressure on the industry to develop a new technique is ever increasing.