Structalit® 5858 is a modified, one-component epoxy resin adhesive that was developed specifically for bonding magnets into electric motors. Its high bond strength and impact resistance ensures reliable bonding.

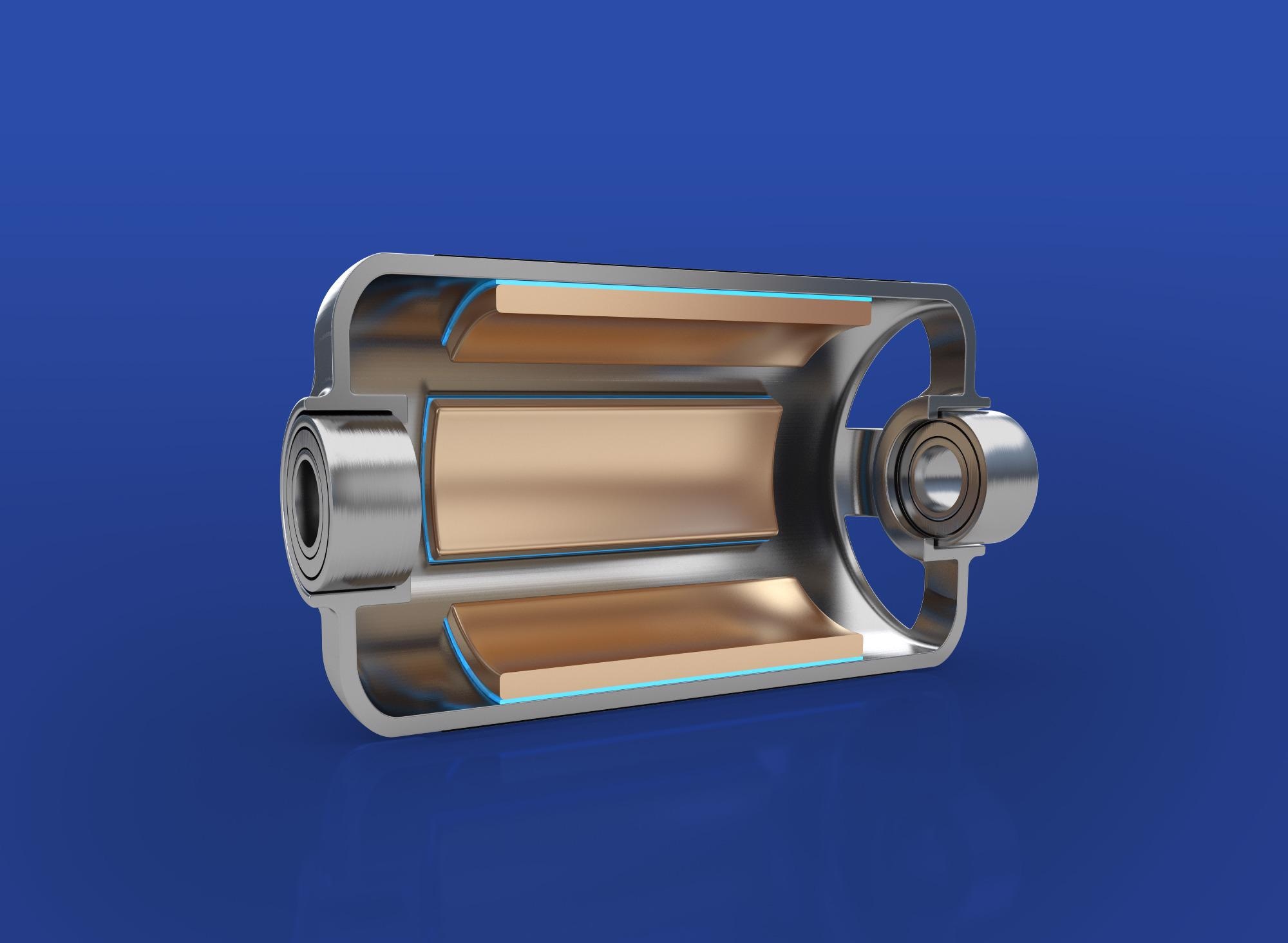

The adhesive marked in light blue shows exemplary magnetic bonding with Structalit® 5858 in an electric motor. Image Credit: Panacol

Structalit® 5858 can be cured thermally in a conventional oven at temperatures from 100°C. It is also possible to use induction curing for faster polymerization and shorter curing cycles.

The adhesive requires storage between 0-10°C, but its stable viscosity and reactivity allow it to be processed on the line at ambient temperature for up to seven days.

The Structalit® 5858 was developed by Panacol to expand its line of adhesives for electric motor assembly. After proper curing, Structalit® 5858 generates excellent adhesion to metals.

With bond strength over 34 MPa on steel and aluminum, this adhesive creates reliable and high-strength bonds. Even at temperatures above 100°C, Structalit® 5858 continues to exhibit excellent superior bond strength, ensuring consistent performance during thermal stress.

The high impact strength of this modified epoxy ensures that bonded components will not loosen or separate from operational vibration or external forces.

Structalit® 5858 is particularly suitable for bonding magnets, such as the connection of half-shell magnets in stators, or permanent magnets on rotors.

Visit Panacol at BondExpo fair from 5 to 8 October 2021 in Stuttgart at stand 5423 in hall 5.