The increasing popularity of 3D printing for manufacturing all kinds of products, from personalized medical devices to economical homes, has generated additional demand for new 3D printing materials engineered for very specific applications.

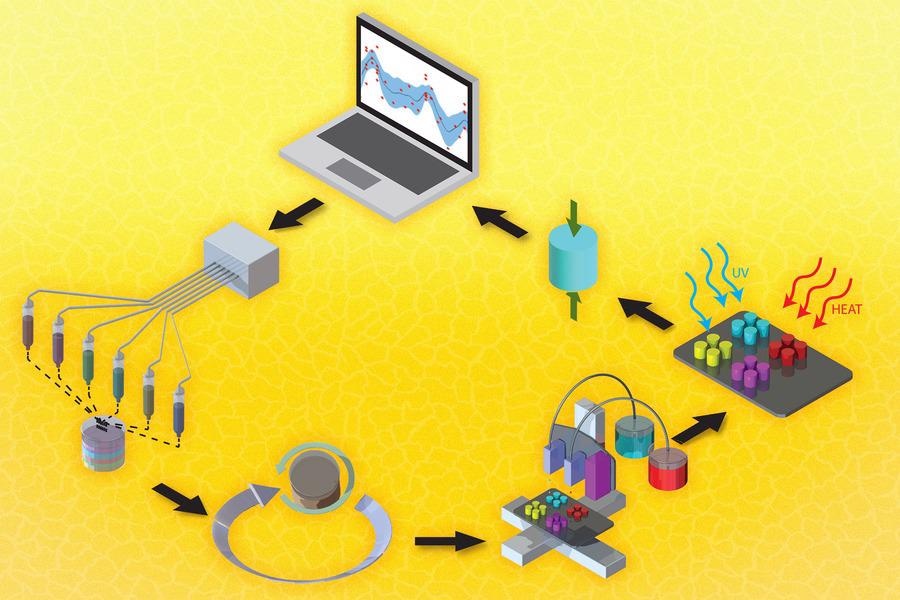

Researchers at MIT and BASF have developed a data-driven system that accelerates the process of discovering new 3D printing materials that have multiple mechanical properties. Image Credit: Courtesy of the researchers.

Researchers at MIT and BASF have developed a data-driven system that accelerates the process of discovering new 3D printing materials that have multiple mechanical properties. Image Credit: Courtesy of the researchers.

To decrease the time taken to discover these new materials, scientists at MIT have formulated a data-driven method that uses machine learning to enhance new 3D printing materials with various characteristics, like compression strength and toughness.

By simplifying materials development, the system reduces costs and diminishes the environmental impact by decreasing the amount of chemical waste. The machine-learning algorithm could also trigger innovation by recommending exclusive chemical formulations that human insight might overlook.

Materials development is still very much a manual process. A chemist goes into a lab, mixes ingredients by hand, makes samples, tests them, and comes to a final formulation. But rather than having a chemist who can only do a couple of iterations over a span of days, our system can do hundreds of iterations over the same time span.

Mike Foshey, Study Co-Lead Author and Mechanical Engineer and Project Manager, Computational Design and Fabrication Group (CDFG), Computer Science and Artificial Intelligence Laboratory (CSAIL)

Additional authors include co-lead author Timothy Erps, a technical associate in CDFG; senior author Wojciech Matusik, professor of electrical engineering and computer science at MIT; Mina Konaković Luković, a CSAIL postdoc; Wan Shou, a former MIT postdoc who is now an assistant professor at the University of Arkansas; and Hanns Hagen Geotzke, Herve Dietsch, and Klaus Stoll of BASF. The research has recently been published in the journal Science Advances.

Optimizing Discovery

In the system the team put together, an optimization algorithm carries out much of the trial-and-error discovery process.

A material developer chooses a few components, inputs particulars about their chemical compositions into the algorithm and outlines the mechanical properties the new material should possess. Then, the algorithm increases and decreases the quantities of those components (like turning dials on an amplifier) and checks how each formula impacts the properties of the material, before attaining the perfect combination.

Next, the developer blends, processes and tests that sample to learn how the material really works. The developer inputs the results into the algorithm, which automatically learns from the experiment and uses the new data to select another formulation to test.

We think, for a number of applications, this would outperform the conventional method because you can rely more heavily on the optimization algorithm to find the optimal solution. You wouldn’t need an expert chemist on hand to preselect the material formulations.

Mike Foshey, Study Co-Lead Author and Mechanical Engineer and Project Manager, Computational Design and Fabrication Group (CDFG), Computer Science and Artificial Intelligence Laboratory (CSAIL)

The scientists have developed a free, open-source materials optimization system known as AutoOED that includes the same enhancement algorithm. AutoOED is a complete software package that also enables scientists to perform their own enhancement.

Making Materials

The scientists tried out the system by using it to enhance formulations for a new 3D printing ink that hardens in the presence of UV light.

They found six chemicals to employ in the formulations and fix the objective of the algorithm to reveal the best-performing material concerning compression modulus (stiffness), toughness and strength.

It would be especially challenging to maximize these three properties manually because they can be conflicting; for example, it is possible that the most robust material may not be the firmest. In a manual procedure, a chemist would normally try to exploit one property at a time, resulting in a number of experiments and a whole lot of wastage.

The algorithm proposed 12 highest performing materials that had the best tradeoffs of the three varied properties after testing just 120 samples.

Foshey and his team were amazed by the wide range of materials the algorithm could produce and reported that the results were much more varied than they anticipated based on the six components. The system boosts exploration, which could be particularly beneficial in situations when specific material properties cannot be simply discovered instinctively.

Faster in the Future

The process could be further accelerated through the use of more automation. Presently, scientists blend and test each sample manually, but in future versions, robots could run the dispensing and mixing systems, Foshey says.

Going forward, scientists are keen to experiment with this data-driven discovery method for uses beyond the creation of new 3D printing inks.

This has broad applications across materials science in general. For instance, if you wanted to design new types of batteries that were higher efficiency and lower cost, you could use a system like this to do it. Or if you wanted to optimize paint for a car that performed well and was environmentally friendly, this system could do that, too.

Mike Foshey, Study Co-Lead Author and Mechanical Engineer and Project Manager, Computational Design and Fabrication Group (CDFG), Computer Science and Artificial Intelligence Laboratory (CSAIL)

As it presents a systematic method for finding optimal materials, this study could be a huge step toward attaining high-performance structures, says Keith A. Brown, assistant professor in the Department of Mechanical Engineering at Boston University.

The focus on novel material formulations is particularly encouraging as this is a factor that is often overlooked by researchers who are constrained by commercially available materials. And the combination of data-driven methods and experimental science allows the team to identify materials in an efficient manner.

Keith A. Brown, Assistant Professor, Department of Mechanical Engineering, Boston University

“Since experimental efficiency is something with which all experimenters can identify, the methods here have a chance of motivating the community to adopt more data-driven practices,” added Brown.

The study received support from BASF.

Journal Reference:

Erps, T., et al. (2021) Accelerated discovery of 3D printing materials using data-driven multiobjective optimization. Science Advances. doi.org/10.1126/sciadv.abf7435.