In one of the astonishing abundances of nature, a safe food-grade solvent has been employed to extract extremely sought rare-earth metals from coal ash, decreasing the quantity of ash without harming the environment and simultaneously increasing a crucial national resource.

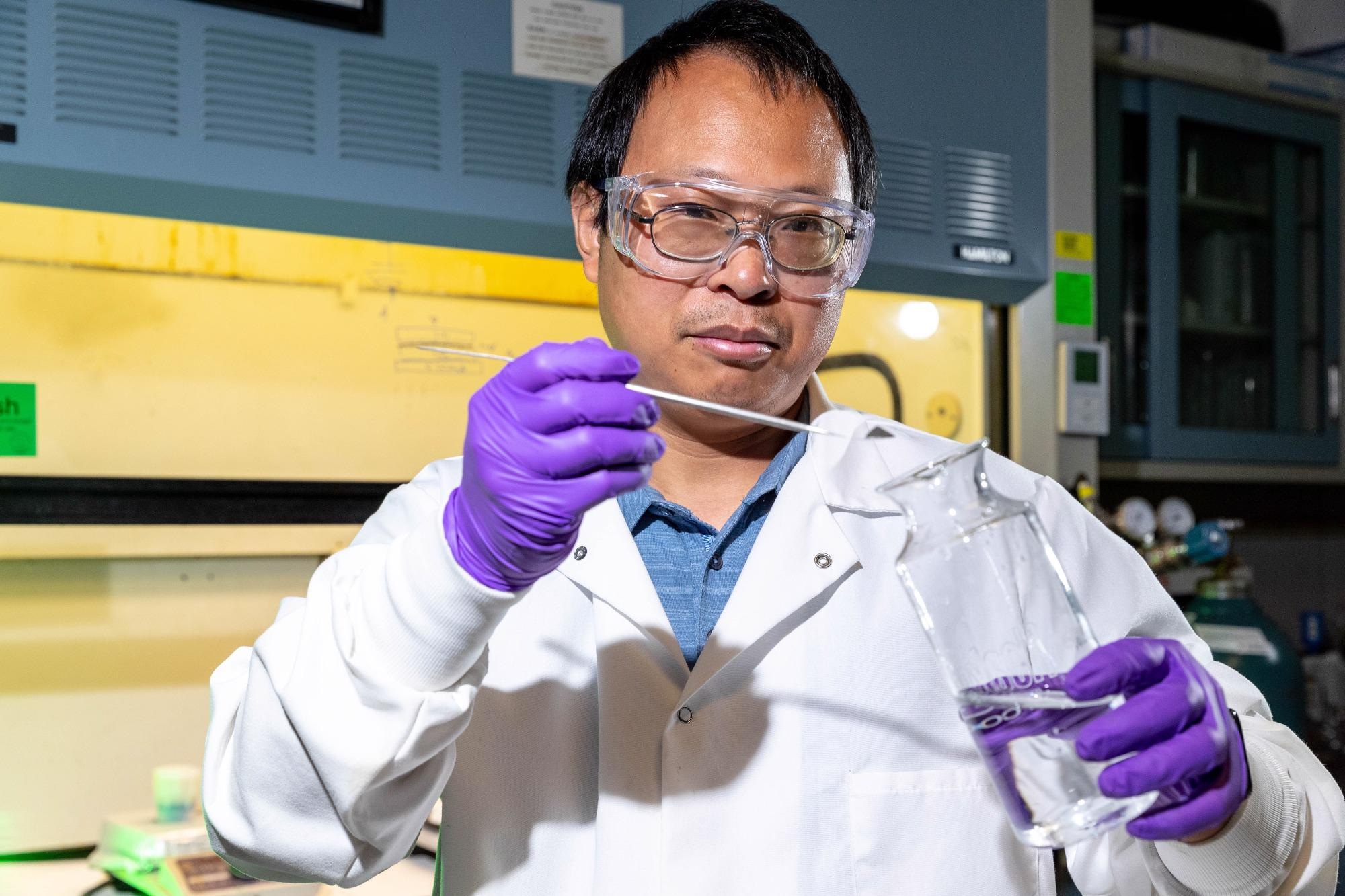

Sandia National Laboratories researcher Guangping Xu adds coal ash into a citric acid mixture. This solution will be fed into a reactor—operating at about 70 times atmospheric pressure—where supercritical carbon dioxide aids citric acid in extracting rare-earth metals. Image Credit: Rebecca Lynne Gustaf

Sandia National Laboratories researcher Guangping Xu adds coal ash into a citric acid mixture. This solution will be fed into a reactor—operating at about 70 times atmospheric pressure—where supercritical carbon dioxide aids citric acid in extracting rare-earth metals. Image Credit: Rebecca Lynne Gustaf

Coal ash is the undesired but commonly present residue of coal-driven power. Rare-earth metals are employed for a range of modern equipment, from submarines to smartphones.

The separation technique, which uses water, carbon dioxide, and food-grade citric acid, is the topic of a patent application at Sandia National Laboratories.

This technique not only recovers rare-earth metals in an environmentally harmless manner but would actually improve environments by reducing the toxicity of coal waste dotting America.

Guangping Xu, Study Lead Researcher, Sandia National Laboratories

“Harmless extraction of rare-earth metals from coal ash not only provides a national source of materials essential for computer chips, smartphones, and other high-tech products—including fighter jets and submarines—but also makes the coal ash cleaner and less toxic, enabling its direct reuse as concrete filler or agricultural topsoil,” Xu added.

The technique, if extensively adopted, could render coal ash, presently an environmental pariah, into a commercially viable product.

Environmentally Friendly Method for Mining Rare-Earth Metals

The most standard acids employed as chemical separators in mining—sulfuric, nitric, or phosphoric acids—also can extract rare-earth metals from coal ash but generate large quantities of acid waste, worsening the environment, Xu said.

Environmentally harmful acids would raise clean-up costs beyond economic feasibility in the United States.

Guangping Xu, Study Lead Researcher, Sandia National Laboratories

The Sandia technique executed by Xu employs citric acid as a carrier for rare-earth metals to separate from coal ash, the host material. The extraction process is enabled by using supercritical carbon dioxide solvent. Xu’s Sandia colleague Yongliang Xiong recommended citric acid, a regularly used and eco-friendly chemical for holding metals in solution.

Xu discovered that within a day, at 158°F (70°C) and 1,100 pounds per square inch pressure (around 70 times standard atmospheric pressure), the technique extracted 42% of rare-earth metals that were available in coal waste samples.

About 95% of the world’s resources of rare-earth metals are found in Chinese mines. These mines perform less efficient separation while using environmentally harmful techniques.

Theoretically, an American company could use this technique to mine coal and coal byproducts for rare-earth metals and compete with Chinese mining.

Guangping Xu, Study Lead Researcher, Sandia National Laboratories

Moreover, for United States national security, “it is probably reasonable to have alternate sources of rare-earth metals to avoid being at the mercy of a foreign supply,” he stated.

Decontaminating coal ash merely for reuse should be beneficial, Xu said. There is no scarcity of coal ash as a raw material. According to a study reported in 2016 in the journal Environmental Science & Technology, “Approximately 115 million metric tons of coal combustion products are generated annually, and this sum includes 45 million tons of fly ash,” the lightest type of coal ash.

These numbers are of interest even today, explained Xu.

“If we don’t detoxify and reuse the coal ash, then it will be abandoned in ponds and landfills and cost billions of dollars to clean up over the long term,” he said. To assist in making that outcome less probable, “We expect tests of our extraction techniques at larger volumes and on a variety of coal-based sources in the near future.”

Carbon Sequestration Also a Possibility

This technology could also pave the way for carbon dioxide utilization and sequestration said Xu’s Sandia colleague Mark Rigali. Along with Xu, Rigali examines the use of citric acid and supercritical carbon dioxide to extract metals from oil and gas shales that are often rich in metals.

“Using existing oil and gas fracking wells, the citric acid and supercritical carbon dioxide can be used cost-effectively to mine metals while disposing of carbon dioxide below ground,” Rigali said.

Subsurface storage of the carbon dioxide will prevent it from entering the atmosphere and influencing climate change, Rigali said.

The study is aided by Sandia’s Laboratory Directed Research and Development program.