Technologies such as the Internet of Things (IoT) and portable and wearable electronics are providing applications for multiple industries. However, with the growth of these technologies comes a huge problem: the growing amount of electronic waste. A paper in the journal Advanced Functional Materials considers the pressing need for eco-friendly electronics that can be disposed of at the end of their life cycle with only minimal environmental impact.

Study: Inkjet Printed Disposable High-Rate On-Paper Microsupercapacitors. Image Credit: Chaikom/Shutterstock.com.

On-Paper Microsupercapacitors – A Solution to the Growing Issue of Electronic Waste

On-paper microsupercapacitors (MSCs) have attracted a huge amount of research interest as a solution to the problem of large-scale electronics waste. Due to their long lifecycle, high power density, and fast charging rate, MSCs are particularly attractive candidates for miniaturized electronics and smart systems which can power themselves.

On-paper MSCs are even more attractive due to their eco-friendliness, renewability, and cost-effectiveness.

However, this eco-friendliness comes at the cost of electrochemical performance. This is particularly true of the on-paper MSC’s rate capacity. Developing on-paper MSCs with high electrochemical performance is a focus in the field of microelectronics. Achieving both will create truly green, highly reliable electronics for a variety of important applications.

Making the Fabrication Process More Sustainable with Inkjet Printing

Disposability alone is not enough to create truly eco-friendly MSCs; attention must also be paid to the fabrication process. Traditional fabrication processes make use of toxic and ecologically damaging chemicals and solvents alongside the fossil fuels used to manufacture the components. They also create huge amounts of waste and release toxic by-products into the environment.

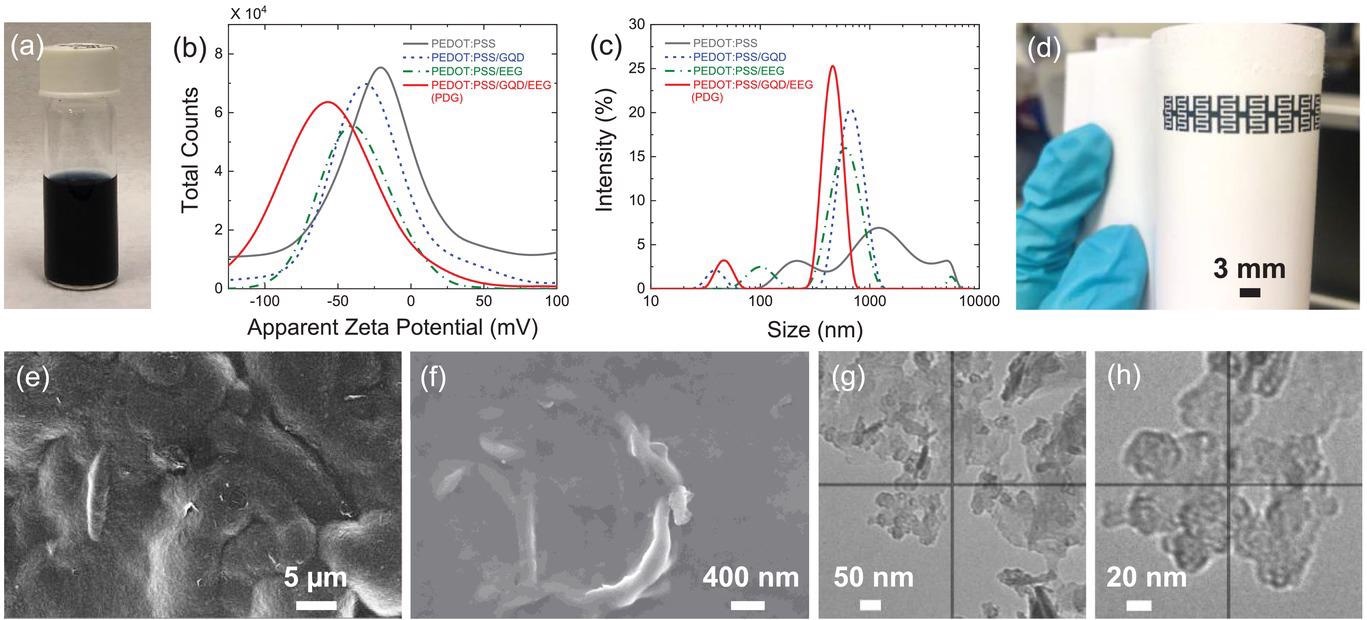

Characterization of the PDG inks. a) Photograph of a PDG ink, b) zeta potential and c) DLS particle size distribution of PEDOT:PSS, PEDOT:PSS/GQD, PEDOT:PSS/EEG, and the ternary PDG dispersions in water/EG mixture (volume ratio 2:1), d) photograph of printed PDG patterns on a photo paper, e,f) SEM images of the printed PDG patterns on a photo paper, g,h) TEM images of the PDG ink. Image Credit: Zheng Li et al., Advanced Functional Materials, Wiley.

A sustainable fabrication technique being explored is inkjet printing. Merits that make inkjet printing an attractive alternative include minimal material waste, scalability, purely additive processing, mask-free patterning, and compatibility with numerous active materials and substrates.

Paper – A Superior Substrate for Inkjet Printing

Paper is a superior substrate due to its compatibility with inkjet printing. This is due to its hierarchical cellulose fiber structure. It is porous, has a rough surface texture, and its capillaries facilitate superior absorption of the ink patterns, leading to the quick formation of printed patterns.

However, there are several challenges concerning inkjet printing and paper that need to be ironed out. Firstly, inkjet printing is good at creating thin patterns with high resolution, but MSCs require thick electrode patterns (this increases the areal performance).

Secondly, paper is not compatible with nonvolatile or aggressive solvents due to strong absorption. Finally, paper is vulnerable to post-treatments such as high-temperature sintering.

These factors make it difficult to fabricate highly conductive patterns on paper substrates with inkjet printing techniques, meaning that rate performance is affected. This makes commercially viable on-paper MSCs difficult to realize.

A New Way to Fabricate Eco-Friendly On-Paper MSCs With High Electrochemical Performance

In a new study in Advanced Functional Materials, a simple, reliable inkjet printing technique to create eco-friendly on-paper MSCs with superior electrochemical performance (such as capacitance rates of 84% after 4 months) was demonstrated.

The research team developed eco-friendly and binder-free conductive inks based on the ternary composite of PEDOT:PSS, graphene quantum dots (GDQs), and electrochemically exfoliated graphene (EEG), dispersed in a water/ethylene glycol solvent. GDQs and EEG both stabilized the PEDOT:PSS-based ink and significantly improved the rate capacity of the MSCs.

The resulting ink is highly stable, facilitating reliable and efficient printing of an on-paper MSC.

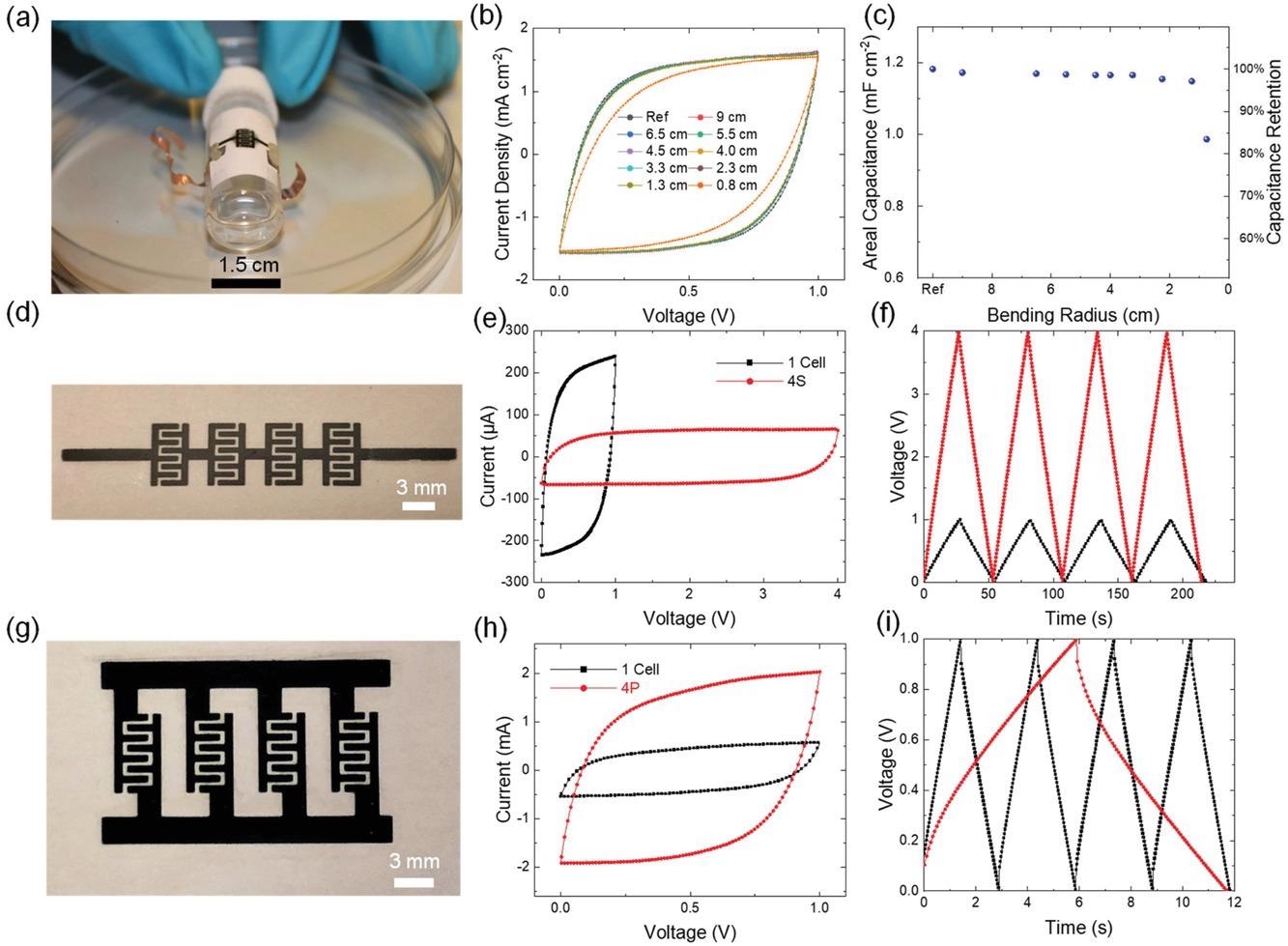

a) Photograph of a MSC printed on photo paper for flexibility performance test, b) the CV curves at 1000 mV s−1 and c) areal capacitance of the MSC under different mechanic bending radii, d) photograph of a fully-printed MSC array with four MSCs connected in series on carton paper, e) the CV curves at 1000 mV s−1 and f) GCD curves at 10 µA of the series-connection MSC array, g) photograph of a fully-printed MSC array with four MSCs connected in parallel on carton paper, h) the CV curves at 1000 mV s−1 and i) GCD curves at 200 µA of the parallel-connection MSC array. All the MSCs are printed with 10 passes. In (g), the bus lines are printed with 17 passes. Image Credit: Zheng Li et al., Advanced Functional Materials, Wiley.

The fabrication of the MSC is simple, with only two steps – printing of electrodes and drop-casting of electrolytes.

The printer used for electrode printing was the Diamatic Materials Printer from Fujifilm Inc. The printer used 10pL cartridges, and the paper used was commercially available paper from Staples as well as Korsnäs carton paper. The ink was allowed to dry before subsequent layer printing to avoid deformation, and the final paper was air-dried.

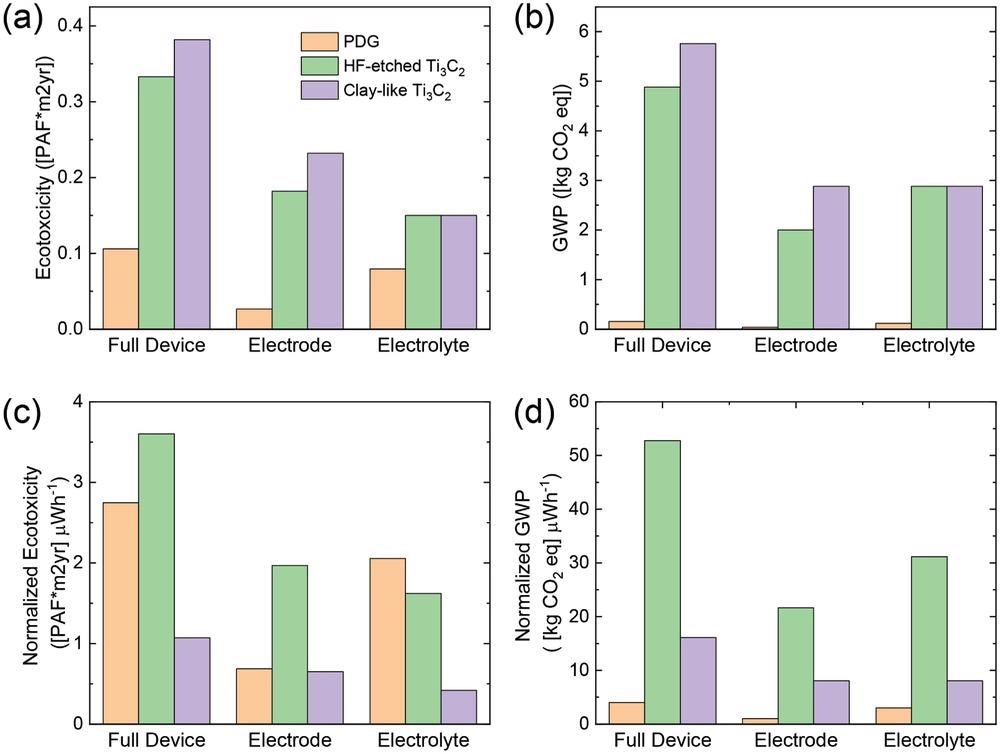

Each MSC was then treated with a simple electrolyte, a mix of poly(styrenesulfonic acid) and H3PO4. After overnight drying in a fume hood, the MSCs were electrochemically characterized. TEM samples were prepared for material characterization. A lifecycle assessment was performed with SimaPro software. GWP and ecotoxicity were studied with the IPCC 2013 GWP 100a and ECO-indicator 99 (H) methods.

Life cycle assessment results for the PDG MSCs (10 printing passes) and MXene-based on-paper MSCs. a) Ecotoxicity, b) global warming potential (GWP), c) normalized ecotoxicity, and d) normalized GWP for the three kinds of on-paper MSCs in consideration of full device, electrode (including paper substrate and current collectors), and only electrolyte, respectively. In (c,d), the normalization is over the maximum energy that can be stored by the MSCs. Image Credit: Zheng Li et al., Advanced Functional Materials, Wiley.

Data gathered from electrochemical and material characterization along with ecotoxicity and GWP potential demonstrated favorable results for inkjet printing eco-friendly and reliable MSCs with this method.

The Future

On-paper MSCs show huge potential to move the field of electronics forward into a sustainable future. Research like the study in this article is helping to develop truly eco-friendly microsupercapacitors that can be easily disposed of at the end of their life cycle, with the performance necessary to make them commercially viable.

Further Reading

Li, Z et al. (2021) Inkjet Printed Disposable High-Rate On-Paper Microsupercapacitors [online] Advanced Functional Materials. Available at:

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.