New research in the journal Materials has thoroughly assessed the commercialization of Perovskite solar cells (PSC). The various methods, processes, market analyses, cost analyses, and hazards have all been thoroughly assessed in view of the commercial expansion of Perovskite cells.

Study: Progress in Perovskite Solar Cells towards Commercialization—A Review. Image Credit: NJH Photography/Shutterstock.com

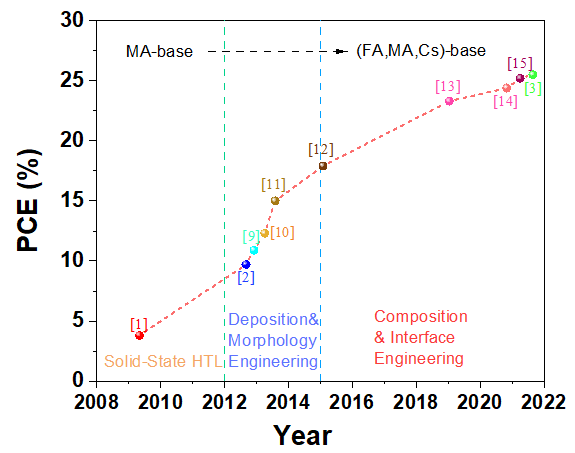

According to the latest study, the initial efficiency of cells was calculated as 3.8% by the inclusion of CH3NH3PbI3 (MAPbI3) photosensitizer dye-sensitized solar cells. However, with the technological advancements, it was increased up to 9.7%. The rigorous need is to push large-area PSC growth to popularize PSCs from the research lab to the solar cell industry.

The research focused on the recent developments in highly efficient PCS cells, the fabrication and optimization methods, an overview of device stability, an overview of economic constraints and safety issues, and possible solutions to several issues.

Performance Improvement and Market Analysis

According to the study, the PCE has increased to almost 25% in the market. This shows that they are credible competitors of classic silicon solar cells as well as the cadmium telluride solar cells. The optimization of the charge carrier channels is also linked to improved performance.

An optimal transport layer can effectively remove the carrier from the absorption layer and carry it to the front cathode, often with a high carrier movement, appropriate band orientation, and high-quality material.

Scalable Coating Methods

Highly efficient PSCs have a surface area of fewer than 1 cm2, significantly less than the needed area for solar cell commercialization, whereas the big state-of-the-art area PSM has a surface area of 802 cm2 and a PCE of 11.6 percent. The inadequate large-area film of each stratum after expanding of devices is the fundamental reason for the effectiveness gap between small-area instruments and large-area units.

PCE development process of PSCs. Image Credit: Wang, H. et al., Materials

Slot Die and Spray Coating

The slot-die coating operating component is a manually constructed fluid-die, with one side linked to the pump to remove the precursor ink and the other side with a hydrodynamic metal die to generate regular wet films. On the high-temperature platform, both the solvent evaporation and the crystallization rate are high, therefore the spray coating process employs injectors to sprinkle highly distributed drops on the surface.

Physical Methods

Some physical processes can also quickly remove solvent and produce top-notch films. Chiang et al., for example, used a concentrated solution and solvent tempering to create perovskite film, with the film with casting engineering having a larger grain size and less grain boundary than the comparison group, and a PCE of 14.3 percent for PSMs (active area of 25.2 cm2).

Stability of PSCs

The researchers found that for single-junction instruments, the PCE has just surpassed 25%. Nonetheless, inadequate long-term reliability remains a major stumbling block for organizational tools, which has been one of PSCs' most pressing development difficulties. Inorganic HTMs outperform organic HTMs in terms of physical and chemical durability, hole movement, ease of fabrication, and affordability.

The misaligned band orientation and poor conductance are the main causes, which will cause hole buildup at the perovskite contact and raise the charge recombination process.

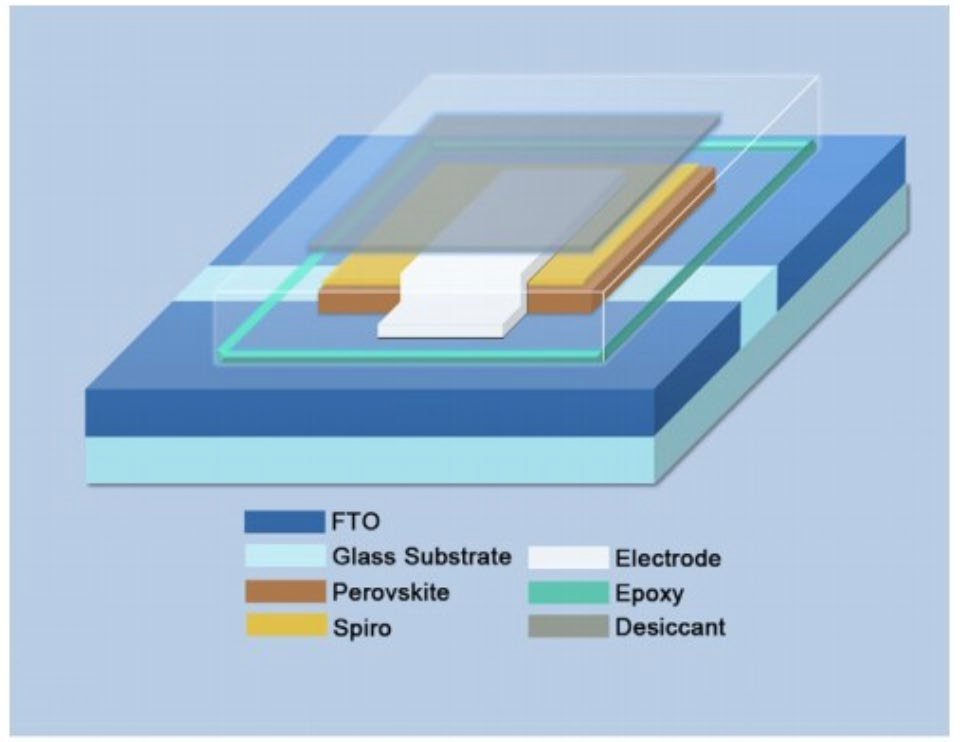

Encapsulation and Commercialization

The research has shown that there is still space to enhance existing packaging technologies during the commercialization phase. One of the most important technical challenges in enclosing is how to design the electrode removal mechanism and achieve proper device closure. Furthermore, we must pay particular attention to the development of innovative packaging substances with greater permeability and higher durability in order to decrease the performance loss caused by encapsulation.

The encapsulation strategies of PSCs. Image Credit: Wang, H. et al., Materials

Risk Analysis

According to the study, as there is the presence of Pb in photo-active layers, PSCs suffer the same safety difficulties that hampered the commercialization of CdTe solar cells. CdTe was shown to be stable and unlikely to generate Cd leakage, but the situation in perovskite was less promising.

Although high-quality packing innovation can reduce the danger of Pb leaking into the ecosystem, it must be accompanied by a strategy that allows items to be called back when they approach the end of their useful life, as First-Solar Corp did for its CdTe photovoltaic devices.

Cost Analysis

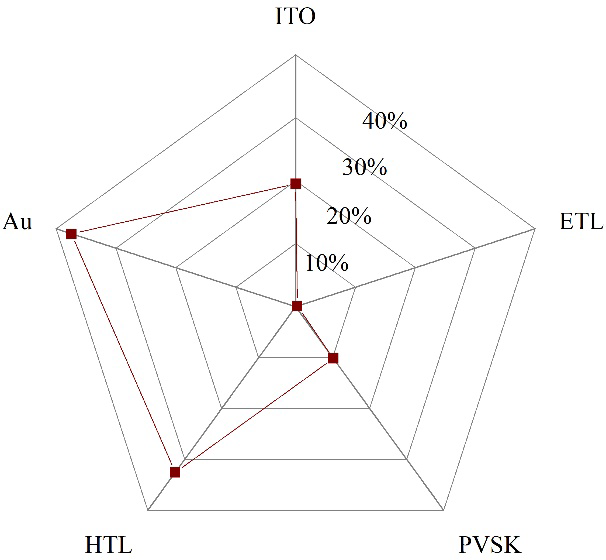

The researchers discovered that the Spiro and perovskite layers represented 65 percent and 29 percent of the overall cost of a single cell with a 2.5 cm x 2.5 cm area created in the laboratory, respectively. The reduction in raw material cost, replacement of electrodes with less pricy effective carbon electrodes, and efficiency improvement would prove them to be cost-effective.

In short, there has been rapid development in the commercialization of such cells. The novel design and fabrication mechanism as well as the encapsulation techniques have contributed immensely to the industrial expansion of these products. But still, research is required in several areas to further increase efficiency and decrease operational costs.

Overall, assessing the trends from a few years, it is evident that Perovskite cells are being commercialized globally and would continue to do so rapidly in the near future.

The cost proportion of materials used in laboratory small-area PSCs. Image Credit: Wang, H. et al., Materials

References

Wang, H., Wang, Y., Xuan, Z., Chen, T., Zhang, J., Hao, X., . . . Zhao, D. (2021). Progress in Perovskite Solar Cells towards Commercialization—A Review. Materials. https://www.mdpi.com/1996-1944/14/21/6569

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.