Concrete production weighs heavy on the environment, responsible for around 50% of overall waste generated worldwide. Recently, a team of researchers from Spain and Portugal has conducted a study, published in the journal Materials, evaluating how recycled concrete could be protected using bioproducts and microbial structures.

Study: Use of Mixed Microbial Cultures to Protect Recycled Concrete Surfaces: A Preliminary Study. Image Credit: Coastal Girl/Shutterstock.com

The study, led by Dr. Andrés Juan-Valdes and Julia Garcia-Gonzalez at the University of Leon, Spain, was conducted to test the capabilities of bioproducts derived from Polyhydroxyalkanoates (PHAs) when applied to concrete as a waterproofing agent.

Astonishingly, the world produces 4 billion metric tons of concrete, making it the most widely used substance on Earth, after water. This comes as a result of population growth and consequent expansion of the urban environment and industry requirements to use large volumes of concrete.

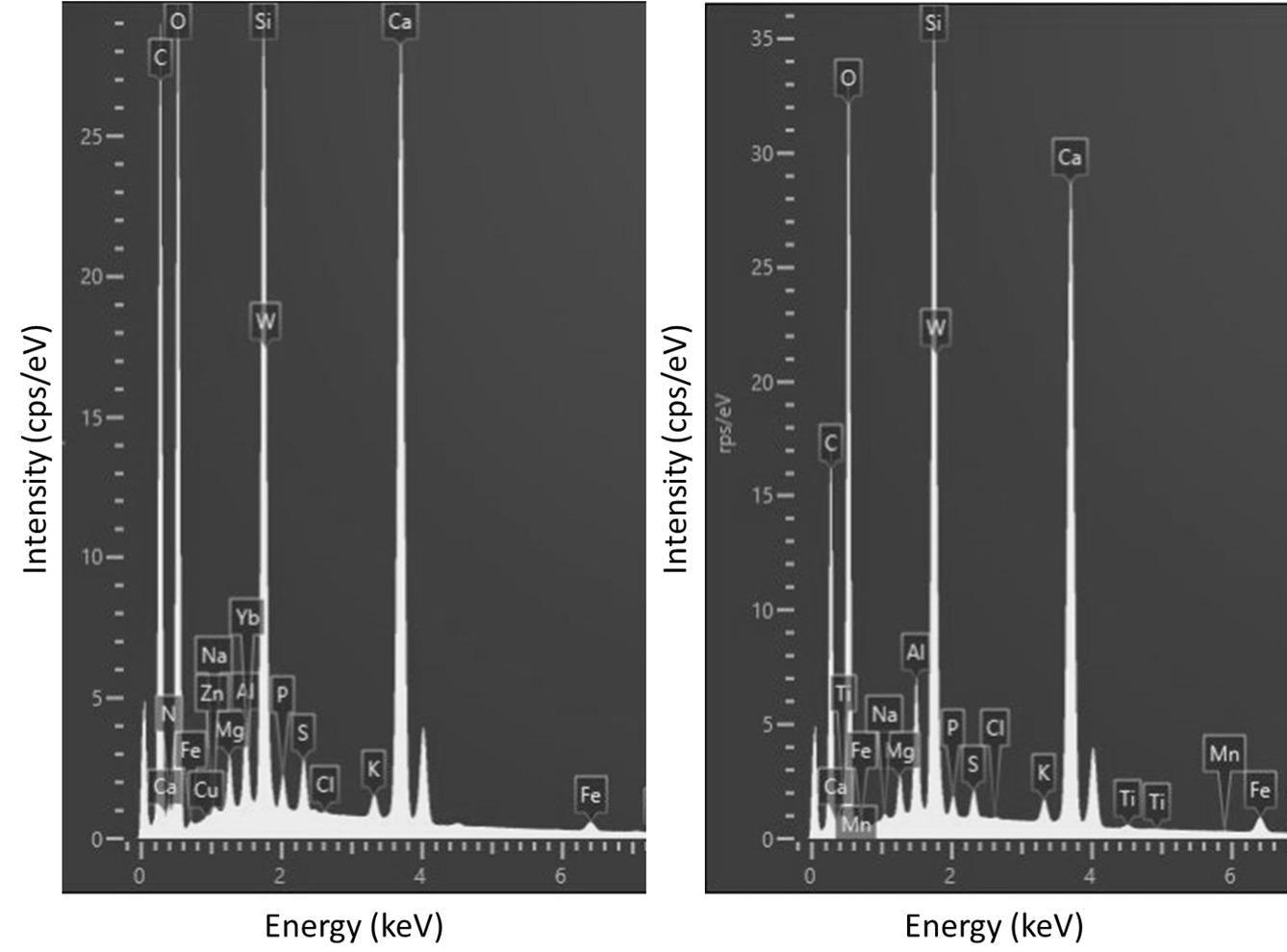

EDS spectra of element content of region 2 on the SP sample on the left and region 1 of the NSP sample on the right. Serrano-González L. et al., Materials

Given the environmental impact of the industry at large—around 8% of greenhouse gases are produced as a result of the concrete industry—there is an effort focused on reducing the carbon footprint of concrete.

Currently, it produces more CO2 than aviation fuel, and if it were a country the concrete industry would be the third-largest producer of greenhouse gases behind the US and China. Therefore, increasing recycling measures would have a positive effect, including increasing the lifespan of the material.

“One measure that may be adopted to enhance concrete durability is the use of surface treatments in situ, the application of coatings and impregnation treatments that may be of utility in conjunction with new types of concretes, produced with innovative materials,” stated Julia Garcia-Gonzalez co-author of the study and researcher at the University of Leon, Spain,

Eco-Friendly Concrete

The development of eco-friendly concrete is not without its challenges, and whilst driven by sustainability, major changes to concrete production, maintenance, and recycling are absolutely necessary. Therefore, extending the lifespan of the material with the application of coatings, treatments, and other innovative materials could address these challenges.

PHAs are biodegradable natural plastics that are primarily synthesized by prokaryotic microorganisms, which makes them both eco-friendly and renewable. Due to the diverse nature of PHAs they can be employed across a range of applications including use in the medical field as well as for food packaging.

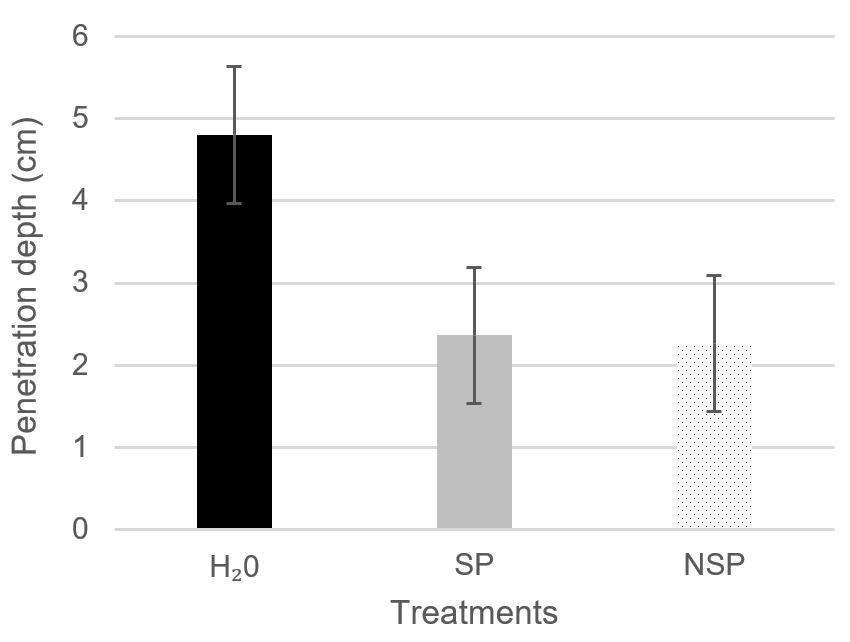

Average penetration depth of water under pressure in water-, SP- and NSP-treated recycled concrete specimens. Image Credit: Serrano-González L. et al., Materials

Furthermore, bioproducts derived from PHAs can also be applied to concrete surfaces, which may increase the durability of the material due to the potential these materials demonstrate for protecting against the ingress of detrimental agents in the environment.

Mixed Microbial Cultures

The bioproducts used in the recent study led by the University of Leon team were produced using mixed microbial cultures (MMC). The MMCs were then subjected to numerous cycles of ultrasonication to yield a bioproduct that could be readily applied to concrete surfaces.

When applied to the concrete surface the product initially showed promising results: “The water repellency generated by the two bioproducts substantially reduced the concrete surface permeability,” Garcia-Gonzales stated.

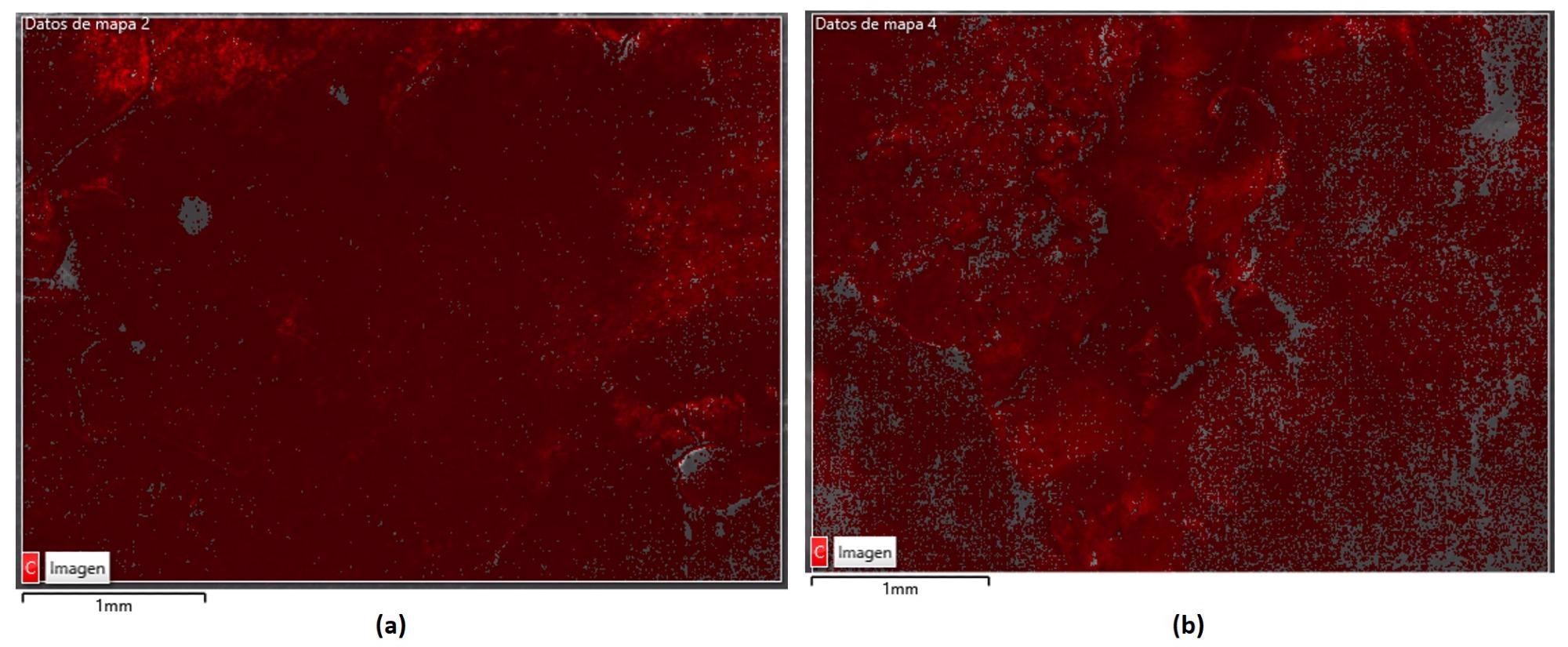

The team subjected the MMC bioproducts to two rounds of testing using energy-dispersive X-ray spectroscopy (EDS) and scanning electron microscopy (SEM). The results showed that the sonicated MMC demonstrated dense clusters formed by high concentrations of the byproducts making these areas more resistant to the penetration of water under pressure.

“The findings of both tests consequently attested a significant decline in recycled concrete surface permeability when coated with the innovative bioproducts, which also constitutes a physical barrier that hinders the penetration of substances that contribute to shorten concrete durability and service life,” said Garcia-Gonzales.

The team was able to conclude that using bioproducts deriving from a PHA-accumulating MMC culture enhanced the durability of the concrete material. This was achieved by increasing the water resistance and making the concrete less-permeable.

Secondary electron image made with SEM, with a layer superimposed with the carbon distribution of regions 2 SP (a) and 1 NSP (b). Image Credit: Serrano-González L. et al., Materials

Furthermore, the sonicated biopolymer exhibited excellent effectiveness under normal atmospheric conditions, making it a prime candidate for real-world application. The sonicated material also demonstrated good structural uniformity making it effective at withstanding higher pressures.

What this means for the future of concrete recycling is that eco-friendly organic surface treatments could be used to significantly increase the lifespan of the material, enhancing durability, preventing deterioration, and making the material more sustainable.

The team claims that enhancing the performance capabilities of concrete would, in turn, encourage the use of recycled CDW aggregates, consequently contributing to a reduction in the volume of waste to manage and decrease the extraction of raw aggregates.

All-in-all this addresses some of the environmental issues associated with concrete production as well as tackles the challenges of recycling concrete.

References

Serrano-González L, Merino-Maldonado D, Guerra-Romero MI, Morán-Del Pozo JM, Lemos PC, Pereira AS, Faria P, García-González J, Juan-Valdés A. Use of Mixed Microbial Cultures to Protect Recycled Concrete Surfaces: A Preliminary Study. Materials. 2021; 14(21):6545. https://www.mdpi.com/1996-1944/14/21/6545

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.