At the productronica trade fair in Munich, Germany, Fluke Process Instruments (booth #A1-325) will present tested and proven temperature profiling systems for quality assurance in electronics manufacturing. The extensive portfolio includes comprehensive hardware and software solutions for both fully automated production lines and for rework and manual inspection.

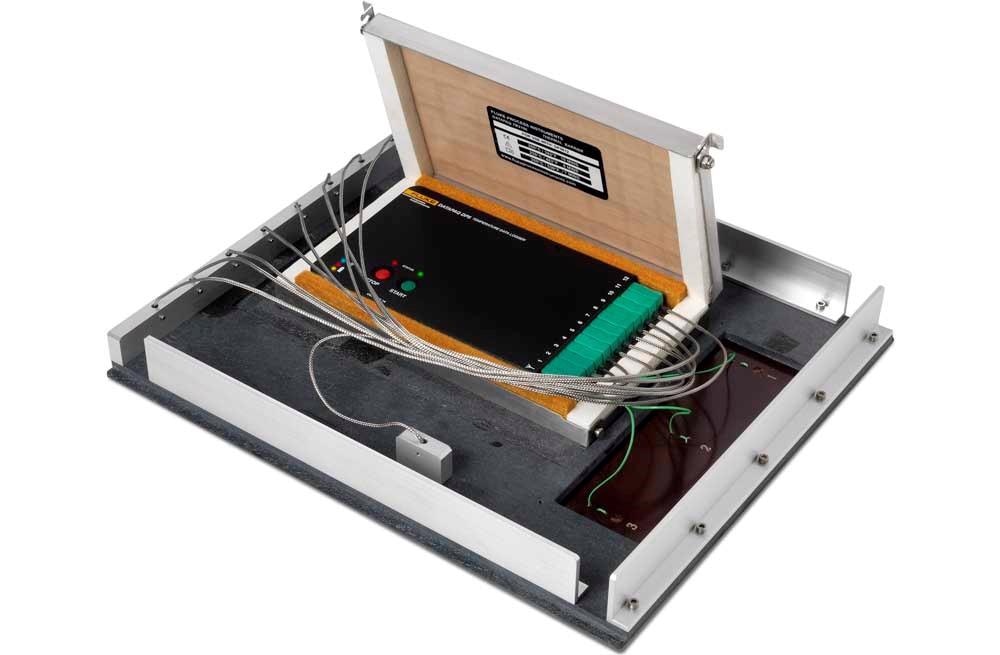

Datapaq Reflow Tracker temperature profiling systems are available with a wide range of data loggers and accessories such as the wave solder pallet here pictured. Image Credit: Fluke Process Instruments EMEA

Datapaq Reflow Tracker temperature profiling systems are available with a wide range of data loggers and accessories such as the wave solder pallet here pictured. Image Credit: Fluke Process Instruments EMEA

These systems travel along with the PCBs through every stage of the process including the preheating phase, capturing detailed temperature profiles along the way based on data gathered by up to 12 sensors. The Datapaq Reflow Tracker line comprises industry-specific data loggers, thermal barriers, a wide selection of thermocouples and the Datapaq Insight software, which quickly transforms raw data into actionable information and features functions for easy oven setup.

The new Datapaq Insight for Mobile app allows users to quickly check thermocouple operation and analyze data on the factory floor, without the need for a PC. The latest generation of data loggers, the Datapaq DP5 series, provides a ±0.5 °C accuracy and a ±0.1 °C resolution.

One logger can survey up to 10 ovens in succession, storing individual profiles with up to 600 k data points in total. Fluke Process Instruments is continuously adding new Datapaq temperature profiling solutions to its portfolio. Standard and customized products are developed in close exchange with customers to optimally suit practical requirements.

In addition, Fluke Process Instruments will also showcase infrared technology for noncontact temperature measurement. Applications for the ThermoView TV40 thermal imager include, amongst others, the quick detection of faulty solder joints. Another highlighted product line, the versatile Raytek Compact MI3 pyrometer series, is designed especially for easy integration in plants and machines and minimal costs per measurement point. The team will be happy to advise productronica visitors on the best way to tackle their specific measurement and monitoring tasks.