Icebreakers, energy storage, gas transporters, hydrocarbon processing and transportation, windmills, drilling equipment, railways, and the transportation sectors all employ high-strength, cryogenic, and cold-resistant steels, as written in the journal Metals. When a specific threshold is surpassed, certain elements that are ductile at ambient temperatures decrease their ductility immediately.

Study: Advanced Trends in Metallurgy and Weldability of High-Strength Cold-Resistant and Cryogenic Steels. Image Credit: DreamerAchieverNoraTarvus/Shutterstock.com

Metals at Cryogenic Temperatures

At low temperatures, standard construction metals, martensitic or ferritic stainless steels as well as chromium, iron, and tungsten, become brittle. Other metals such as silver, copper, gold, nickel, and aluminum are ductile at cryogenic temperatures.

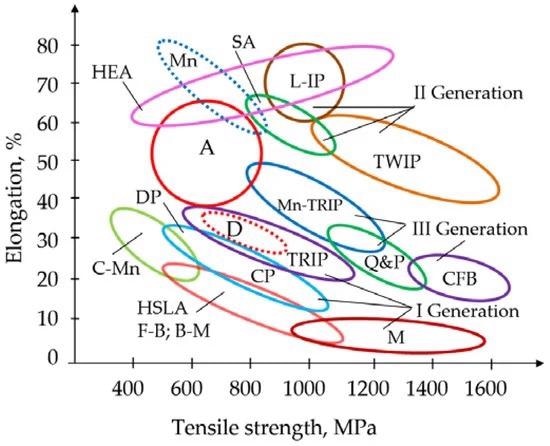

Mechanical properties of HSS and AHSS (Advanced High-Strength Steels) high-strength cold-resistant and cryogenic steels. Image Credit: Rudskoi, A., and Parshin, S., Metals

The development of low-alloy Si-Mn ferritic–pearlitic metals with a less than 0.2 percent carbon content marked the beginning of traditional high-strength steel (HSS) smelting. Through the use of V, Ti, Nb, and Thermal-Mechanical Controlled Processing (TMCP), a fine-grained microstructure was achieved, enhancing rigidity and impact strength and toughness while lowering carbon content by 0.15 percent.

Controlled Process with Heat Treatment

Following the invention of TMCP and the use of rapid cooling with heat treatment, ferritic–martensitic and ferritic–bainitic microstructures of steels with a carbon content of less than 0.1 percent were obtained. These materials have a finely-dispersed structure as well as a maximum impact strength, with scattered and dispersed carbon steels and carbonitrides.

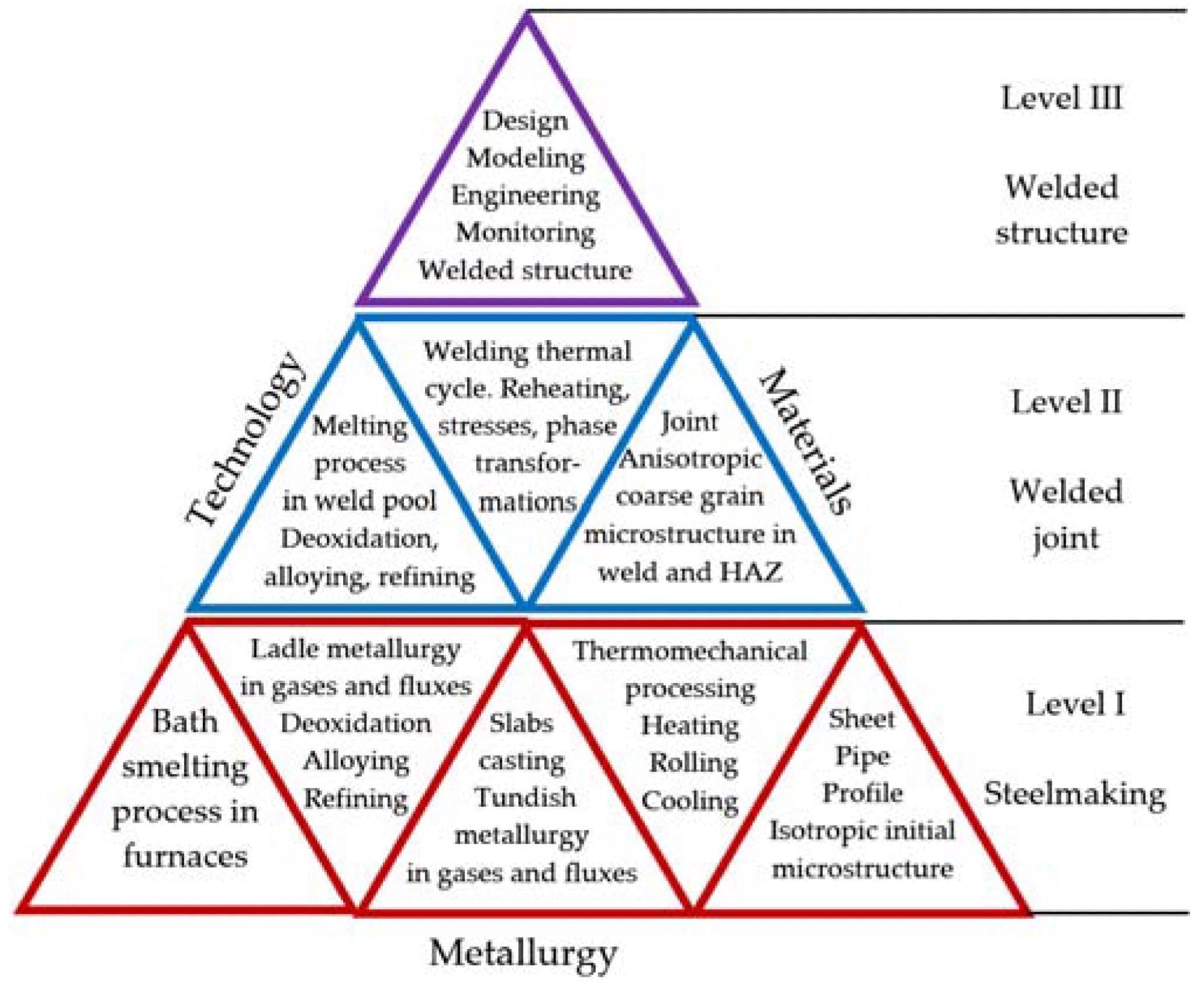

Multi-level system of processes for the manufacturing of welded structures. Image Credit: Rudskoi, A., and Parshin, S., Metals

To increase plasticity and affect the toughness of microalloying, high-strength steels, TMCP efficiency, microstructure improvement, dispersion strengthening, refining, and minimization of rolled steel anisotropy are applied.

Contemporary HSS microstructures include bainitic–martensitic, bainitic, martensitic–bainitic, and martensitic–bainitic, with carbon content ranging from 0.05 to 0.02 percent. Because arc and laser welding are used to construct structures, welding metallurgical and weldability are strongly tied to the manufacture and creation of high-strength steels.

The metallurgy and formability of high-strength steels are now being researched all around the world. The major developments in steelmaking include improving steel durability and impact toughness and strength, increasing efficiency, and lowering alloying costs. About 15 types of low- and high-alloy steels should be separated from classic and modern high-strength steels for low-temperature and cryogenic use.

In the designing and manufacturing of sophisticated high-strength metallic materials, metallurgical advancements are used. TMCP is used in the manufacturing of AHSS.

Because the models and technology for AHSS are targeted at the automobile sector, the steels have a thickness of up to 4 mm. The thermophysical-mechanical concepts of TMCP, thermodynamics modeling, and metallurgical techniques of AHSS-making, on the other hand, may be used to higher-thickness steel production.

![(a) TMCP diagram of HSLA steel Data from [11]. (b) CCT diagram of HSLA steel. Data from [9].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_57466_16378429402599694.jpg)

(a) TMCP diagram of HSLA steel (b) CCT diagram of HSLA steel. Image Credit: Rudskoi, A., and Parshin, S., Metals

Advanced High-Strength Steels

Modern high-strength steels feature a diverse microstructure of the steels such as ferrite, bainite, martensite, and residue austenite, with strengths exceeding 500 MPa. Dual-phase DP steels with F-M microstructure and tensile strengths up to 1400 MPa are included in the first generation of AHSS. The second generation of TWIP steels comprises iron alloy high-manganese steels featuring generated plasticity by twinning and tensile strengths of up to 1650 MPa.

A ferritic or bainitic matrix with a 5–20 percent volume percentage of metastable residual austenite, which converts into martensite under deformation of plastic, make up the microstructure. TRIP steels' high plasticity allows them to be used in folding, stamping, and bending, which is critical in the automobile sector.

The high-strength steels are dual phase steels, TRIP steels, Complex Phase Steels (CP), Superaustenitic Manganese Steels, TWIP Steels, Mn-TRIP—Steels, Q&P Steels, and Carbide-free bainitic (CFB) steels.

Challenges of Manufacturing Cryogenic Steels

The major goals of welding structures for low-temperature applications are to improve reliability and longevity while lowering weight and expense. Boosting steel viscoplasticity, lowering sensitivity to general corrosion and hydrogen cracking, and improving cyclic loads at cold temperatures are all important challenges.

The majority of fractures in steels arise as a result of cracks originating in local stress concentration levels, dislocation agglomerations, inter-granular and interphase barriers, and nonmetallic sharp-edged form intrusions.

Brittle cracks are characterized by low energy absorption and occur when a crack perpetuates through the atomic level by splitting (chipping). Ductile fractures originate with the creation of microporous convergence, with scattered inclusions and carbides spread throughout the viscous matrix as the initiators of rupture.

De-cohesive fractures form at grain borders, which are weaker than the grains, upon microfracture. Even during the segregation of brittle and hazardous impurities, including during the corrosive effect, the strength of intergranular barriers decreases.

Charpy tests are used to investigate the influence of temperatures on impact strength. With a drop in temperature and the incidence of steel embrittlement, microhardness diminishes. Steels undergo brittle fracture at a crucial cold temperature within the ductile-brittle threshold temperature range. To characterize fracture micromechanics, a large variety of physical and analytical concepts have been constructed.

A particular microstructural design should be used in the metallurgical process of advanced high-strength steels for weldment for cold-resistant and cryogenic duty. The impact of welding temperature cycles and strains, as well as recurring phase transitions in the welding process and the heat-affected region, should be considered in steel metallurgical and microstructural development.

References

Rudskoi, A., and Parshin, S. (2021). Advanced Trends in Metallurgy and Weldability of High-Strength Cold-Resistant and Cryogenic Steels. Published: 23 November 2021. https://www.mdpi.com/2075-4701/11/12/1891/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.