In a recent study published in the journal Materials, researchers from Russia analyzed the difference between bending tensile and compressive deformative properties and evaluated the elastic modulus of reinforced concrete spans.

Study: Compressive and Tensile Elastic Properties of Concrete: Empirical Factors in Span Reinforced Structures Design. Image Credit: Bannafarsai_Stock/Shutterstock.com

Researchers found that a 10% increase in elasticity modulus increased the stress by 30-40% and the cracking point stress by 30%. Further, the elastic modulus was found to be dependent upon the mode and duration of the applied load.

Elastic Properties of Concrete

Concrete is a composite with cement as a matrix and aggregates as reinforcements, where the surface of aggregates pins down crack propagations, thus giving it a robust structure.

The elastic modulus of concrete, which determines its stiffness, depends upon several factors such as the volume fraction and maximum size of aggregates, the proportion of coarse aggregates, moisture content, homogeneity of the mixture, and thickness of interfacial transition zone. It also depends on the reinforcement materials such as steel rods, glass particles, and fly ash.

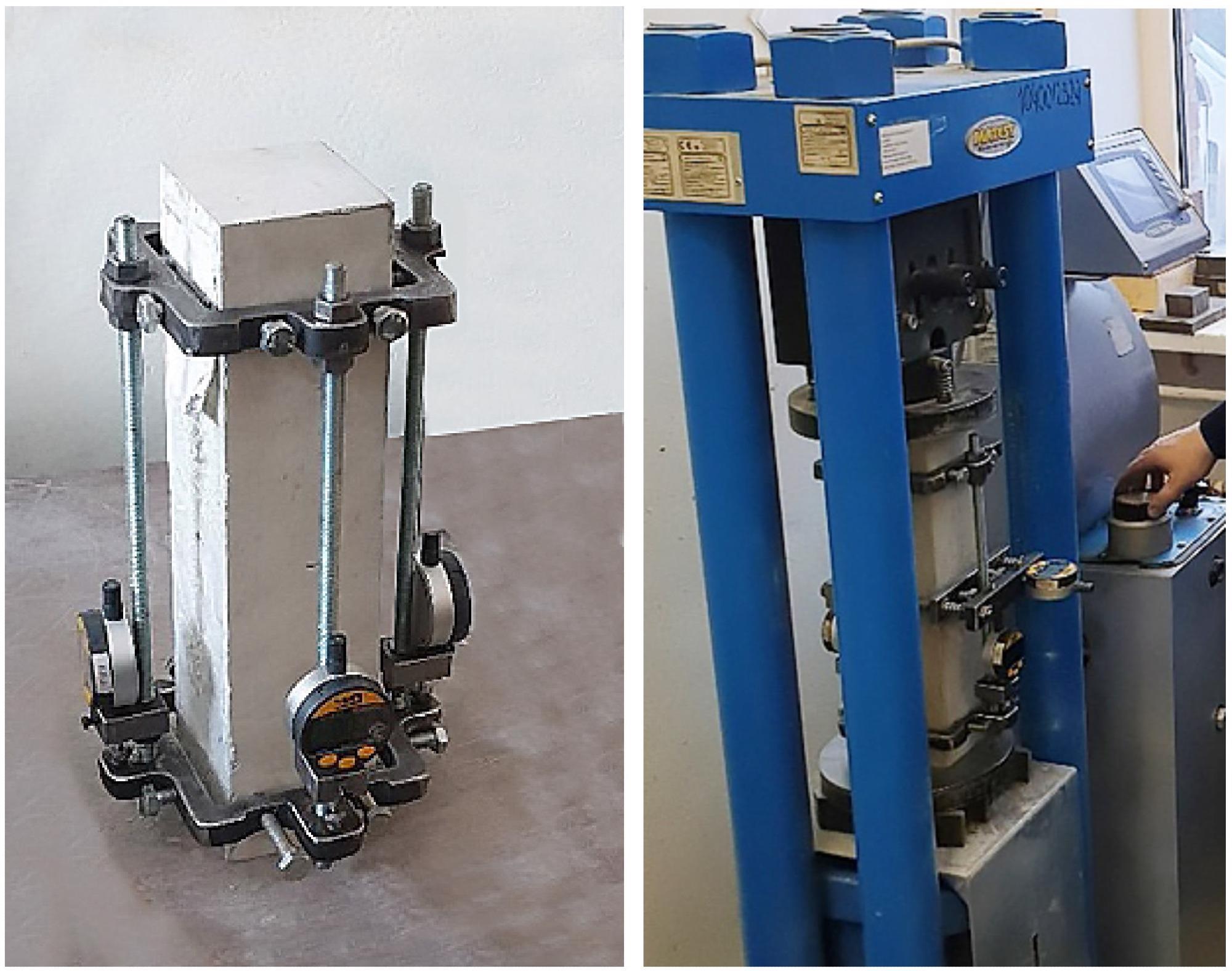

Concrete sample modulus of elasticity under compression testing. Image Credit: Korolev, A et al., Materials

The standard compression test of concrete only considers instant elastic deformation, which provides only instantaneous elastic modulus. For non-linear deformations, this approach provides inaccurate information.

Thus, there is a need to evaluate dynamic elastic moduli throughout the process of deformation to get a clear picture. Moreover, the isotropic theory of elasticity for concrete proposes that the compressive and tensile elasticity should be equal, so the accurate measurement of the difference between these two parameters for all conditions requires modern retesting.

About the Study

In this study, the researchers used Russian state standard (RSS) methods viz. GOST 24452-80 to evaluate the compressive strength, modulus of elasticity, Poisson’s ratio, and methods of prismatic; GOST 22690-2015 to determine the strength by using mechanical nondestructive testing methods; GOST 310.4-81* to measure bending and compression strength.

Two types of concrete samples were used with varying proportions of materials mix namely, heavyweight concrete (HWC), and lightweight concrete (LWC).

Furthermore, the samples were compressed under a hydraulic press by increasing the cracking stress by 10% in stages up to 40%, whereas bending tensile elasticity modulus measurements were performed using digital deformation sensors on each side of samples and by applying mechanical load in stages of 1.5kN with 5 minutes of hold time until breaking.

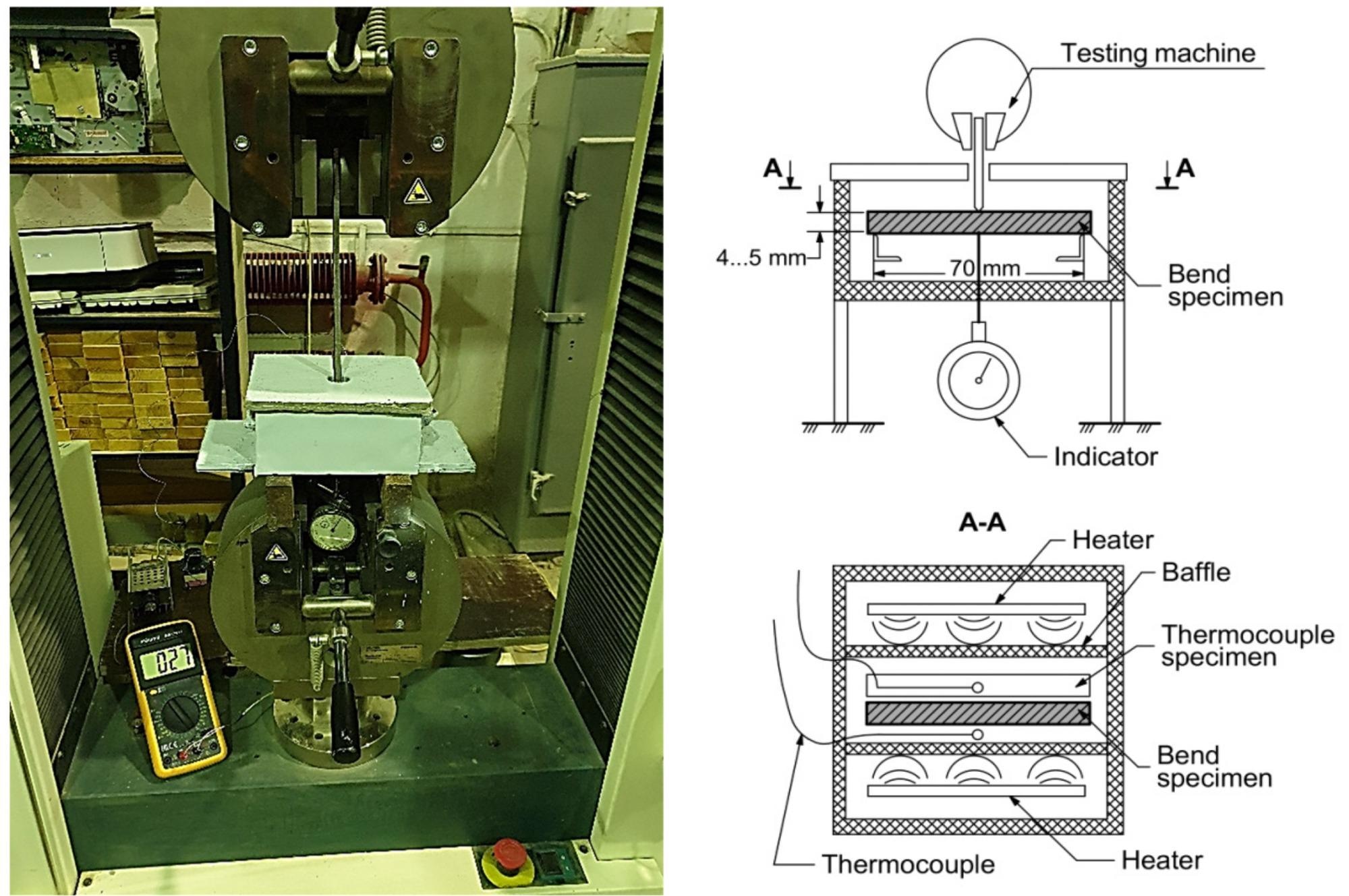

Also, cement hydrated paste samples of dimension 70 x 5 x 5 mm were used on the polymer plate samples testing device to evaluate the elastic modulus.

To study the effectiveness of increasing elasticity, the concrete beam samples of dimension 80 x 140 x 1400 mm were reinforced with an 8 mm diameter composite rod or 10 mm diameter steel.

The three-point bending test rig. Image Credit: Korolev, A et al., Materials

Observations

The samples showed a delayed microcracking until 20% of breaking load due to stress relaxation by the contact zone, but the developments were very fast right before the destruction. Also, for the hydrated cement paste, the bending tensile elastic modulus was several times less than the compression elasticity modulus.

Moreover, the instantaneous compressive elastic deformations were much lower than the tensile elastic deformations, whereas prolonged compressive and tensile elastic deformations were close to each other.

In the case of steel or composite rod-reinforced concrete beams, an increase in the elastic modulus of samples with equal strength resulted in a proportional and insignificant decrease in deflection, but the cracking point stress increased disproportionally.

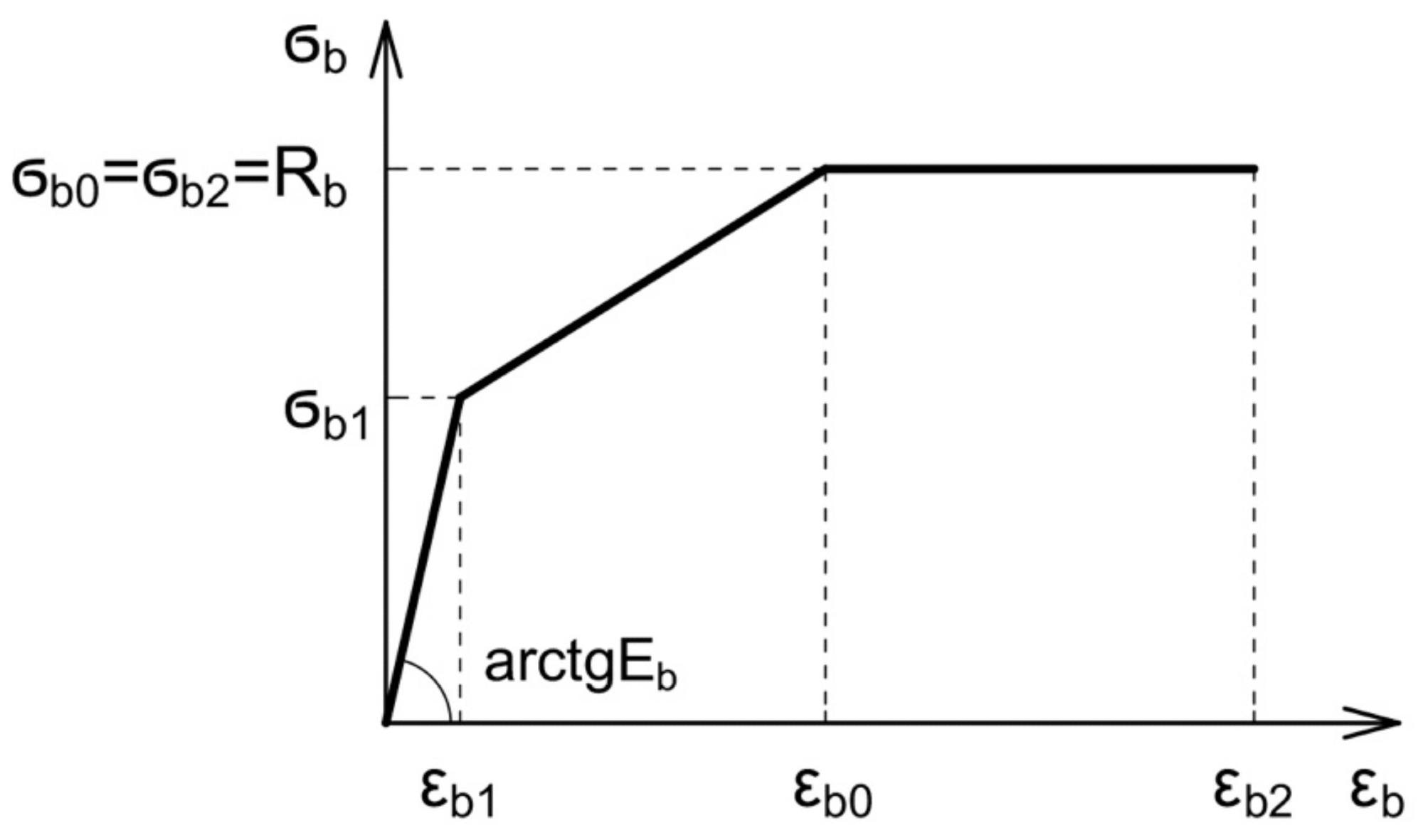

It can be confirmed from the figure that only a 10% increase in the elastic modulus led to a 30% increase in cracking point stress. Additionally, high modulus HWC with low modulus reinforcements showed almost equal cracking point stress to that of normal concrete with a high-modulus composite rod or steel reinforcement. However, LWC demonstrated a decrease in cracking point stress with a decrease in the elastic modulus without any dependency on the strength.

Three-line concrete deformation diagram. Image Credit: Korolev, A et al., Materials

Conclusions

The researchers used Russian state standard methods to evaluate compressive strength, bending tensile strength, and elastic modulus of HWC, LWC, and hydrated cement paste under different stages of mechanical loading.

They found that the three-line non-linear deformation model was inaccurate compared to the two-line model due to the overestimation of deflections and properties of reinforcements. Additionally, under the real-world scenario, where deformations are not instantaneous but prolonged, compressive deformations were close to bending tensile deformations and they are more dependent on the elastic modulus rather than the strength of the concrete structure.

Reference

Korolev, A., Kopp, A., Odnoburcev, D., Loskov, V., Shimanovsky, P., Koroleva, Y., Vatin, N., Compressive and Tensile Elastic Properties of Concrete: Empirical Factors in Span Reinforced Structures Design. Materials, 2021, 14, 7578. https://www.mdpi.com/1996-1944/14/24/7578#cite

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.