A new paper presented in the journal Sustainability aims to explore the potential use of freeze concentration technology in recovering nutrients from digestate. This novel approach could offer a new means of treating the digestate of agro-industrial waste effluents to avoid the groundwater contamination and nutrient saturation commonly associated with this material.

Study: Application of Freeze Concentration Technologies to Valorize Nutrient-Rich Effluents Generated from the Anaerobic Digestion of Agro-Industrial Wastes. Image Credit: Marsan/Shutterstock.com

As global populations continue to increase, there is a growing and urgent demand to maintain sufficient food supplies and to expand capacity to meet the needs of a skyrocketing population.

Efforts to meet this demand have centered around improving the efficiency of agricultural systems – particularly those involving intensive animal production. Animal farming generates significant quantities of manure and other agro-industrial wastes, with many farming communities using this livestock manure as a valuable source of organic fertilizer.

Livestock manure continues to represent one of the most prevalent sources of biowaste, with research showing that its levels of nutrients - such as nitrogen and phosphorous - offer a robust alternative to chemical fertilization. The use of manure over chemical fertilizers is considerably more sustainable than its synthetic counterpart while improving soil quality and achieving high crop yields.

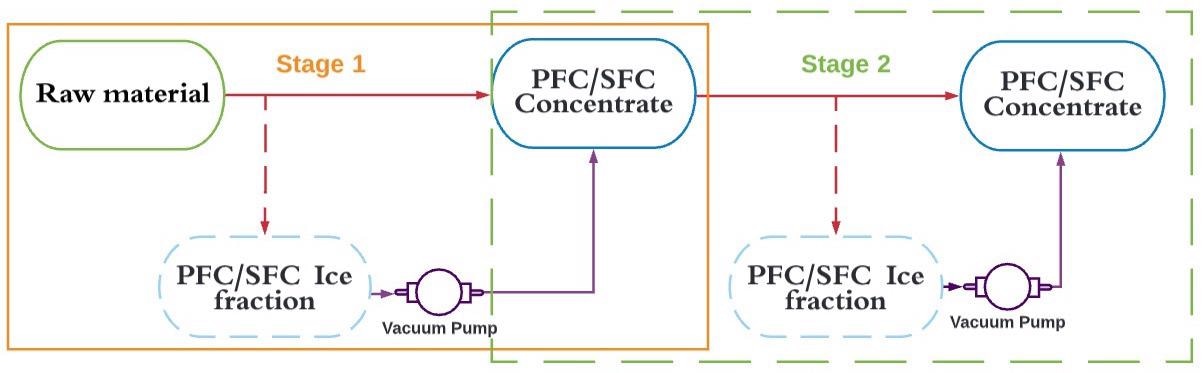

Flowchart of the experimental setup performed through PFC and SFC in two freezing stages of the digestated manure. Image Credit: Uald-lamkaddam, I et al., Sustainability

Livestock manure is therefore often transported to nutrient-deficient croplands to help improve these, but because livestock manure is bulky and must be carefully stored, transporting this over long distances is expensive, less energy-efficient, and may potentially negate any sustainability benefits afforded by its use.

Because of this, a great deal of research has been conducted into cost-effective, efficient approaches to optimize the concentrations of livestock manures. Various technologies have already been explored in this regard; for example, anaerobic digestion, compaction, gasification, thermochemical conversion, filtration, composting, hydrothermal carbonization, evaporation, and liquefaction.

These technologies have been scaled-up over time, allowing them to better optimize key factors such as energy recovery, volume reduction, and nutrient concentration; but many of these methods face notable limitations in terms of cost, energy usage, maintenance requirements, and the need for expensive equipment and capital expenditure.

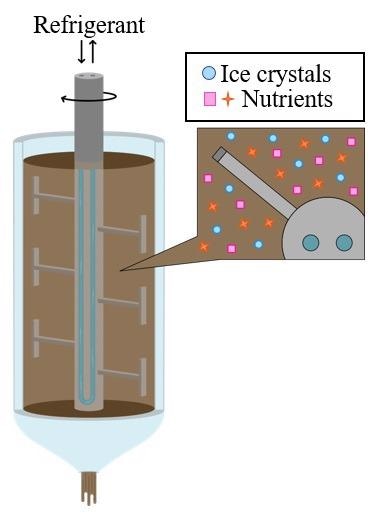

Ice formation during suspension freeze concentration process. Image Credit: Uald-lamkaddam, I et al., Sustainability

The growing interest in freeze concentration technology is primarily driven by the quality of products obtained from this process. This approach sees solutes removed from water by freezing. Once a high purity of crystallized water has been achieved, the concentrated fluid is then separated from the formed ice.

This method offers a high separation factor, lower energy usage than many of its peers, and uses easily available equipment. It is also free of chemicals.

Freeze concentration has seen widespread adoption in the food, beverage, wastewater treatment, and desalination sectors, but the authors point out that little research has been done into the applicability of this technology in the recovery of nutrients from animal manures, slurries, or digestates.

They, therefore, looked to evaluate the efficiency and applicability of freeze concentration technology when used for the recovery of nitrogen, phosphorus, and potassium from agro-industrial waste.

The study utilized a concentrated digestate of pig slurry with a view to delivering a nutrient-rich solution with potential for use as an agricultural biofertilizer or a diluted fraction for use in nitrate-vulnerable zones.

As well as assessing the method’s efficiency in terms of nutrient recovery, they also investigated its energy consumption – another key factor in establishing freeze concentration as a sustainable option. Its heavy metals content was also assessed – an important consideration in ensuring minimal environmental impact, consumer safety, and regulatory compliance.

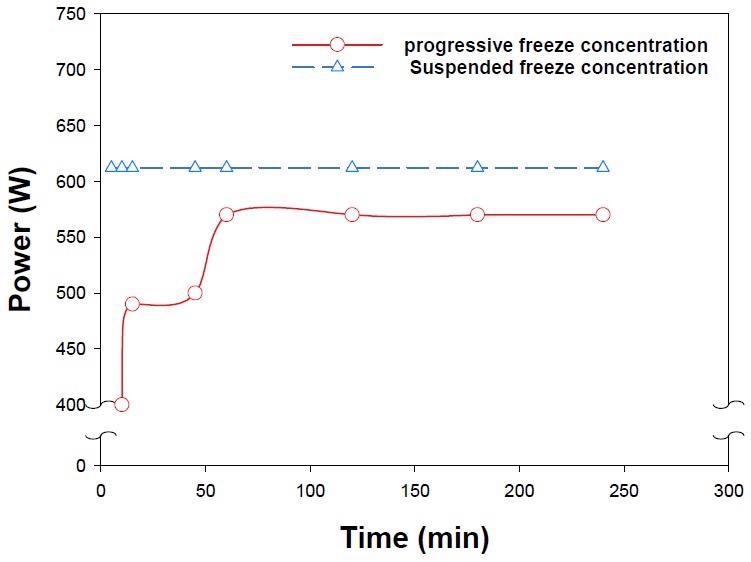

Two methodological approaches were investigated: a progressive freeze concentration (PFC) and a suspension freeze concentration (SFC); both of which were completed in multiple stages.

These methods were evaluated using a range of lab-scale configurations, while various techniques and models were used to quantify and assess the methods’ recovery of nitrogen, phosphorus, potassium, and total solids. These included calculations revealing nutrient recovery, process efficiency, yield, and other key factors.

Power used during the progressive freeze concentration and suspended freeze concentration. Image Credit: Uald-lamkaddam, I et al., Sustainability

The study’s results showed a great deal of promise, with excellent process efficiency. The application of freeze concentration was found to reduce the volume of the waste, and it was confirmed that each of the two methods investigated had delivered a concentrated fraction that could confidently serve as a nutrient-rich organic fertilizer with levels of heavy metal content in agreement with current regulations.

The diluted fraction could also be delivered as water for irrigation in high-density livestock areas.

Overall, the study verified that the application of freeze concentration could help address two of the major limitations of the use of livestock waste as a means of fertilizing crops: the financial and environmental impact of its bulk transportation and the issues with soil contamination with overly high levels of nutrients or other harmful chemicals.

References

Uald-lamkaddam, Imane, Arezoo Dadrasnia, Laia Llenas, Sergio Ponsá, Joan Colón, Esther Vega, and Mabel Mora. 2021. "Application of Freeze Concentration Technologies to Valorize Nutrient-Rich Effluents Generated from the Anaerobic Digestion of Agro-Industrial Wastes" Sustainability 13, no. 24: 13769. https://www.mdpi.com/2071-1050/13/24/13769#

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.