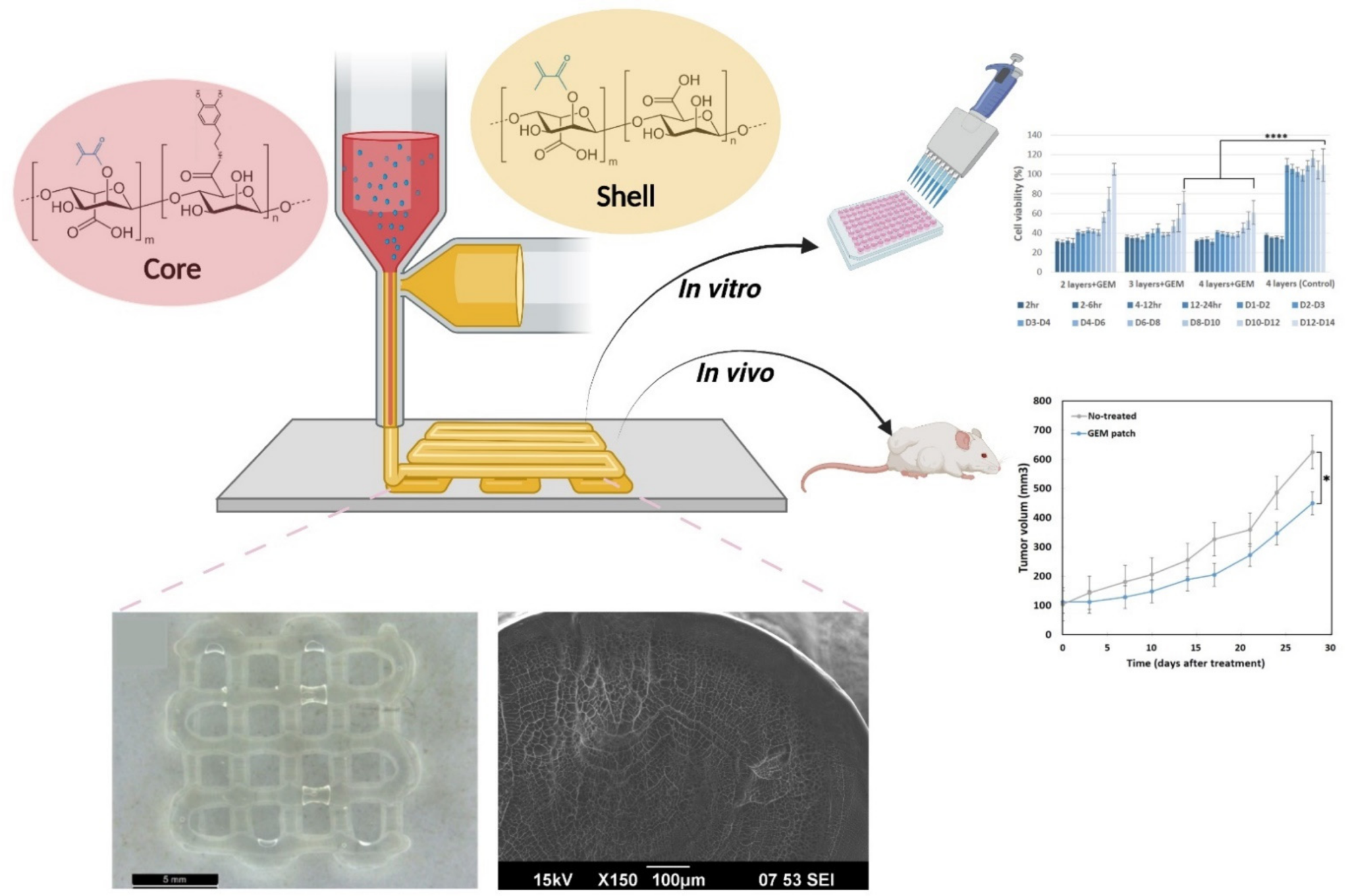

A 3D printing technology was used to create novel findings of coaxial hydrogel patches, as written in the journal Polymers, with the goal of constructing drug-loaded implantable overlays. The center of these patches was made up of a dopamine-combined methacrylated alginate hydrogel that was loaded with a chemotherapy medication (Gemcitabine), while the shell was made up entirely of methacrylated alginate hydrogel.

Study: 3D-Printed Coaxial Hydrogel Patches with Mussel-Inspired Elements for Prolonged Release of Gemcitabine. Image Credit: Mark Heighes/Shutterstock.com

The patches were enhanced with a CaCO3 crosslinking agent and a polylactic acid (PLA) covering to allow for longer drug release. As a consequence, the results revealed that adding CaCO3 to the recipe improved the mechanical characteristics of the patches and reduced their swelling ratio greatly when compared to patches without CaCO3. Interestingly, the insertion of PLA coating to CaCO3 patches lowered their swelling ratio much more, which delayed the release of Gemcitabine substantially.

Schematic showing the 3D printing of coaxial hydrogel patches, their morphology, and the subsequent in vitro and in vivo testing. **** p = 0.0001, * p = 0.05. Image Credit: Talebian, S., et al, Polymers

Cancer Treatment Methods

The treatment methods for cancer are highly dependent on the type and stage of the disease, and a wide range of treatments have been used in clinical trials to date. More particularly, such treatment options aim to address several of the following cancer-related issues: shrinking inoperable cancer cells to make them operable, preventing tumor growth after surgical resection, and eliminating circulating cancer cells in the peripheral circulation in patients with metastasis.

Alongside different lines, systemic administration of pertinent drugs has been widely used to address some of the aforementioned issues, and it has even yielded some promising clinical results.

Traditional Systemic Medication

However, systemic medication delivery is frequently associated with unfavorable outcomes such as high dosage requirements, low absorption, and negative side effects. This sparked a research movement aimed at figuring out other ways to deliver medications locally to the tumor site, in order to avoid the downsides of systemic administration.

As a result, biopolymers have emerged as viable candidates for implanted drug delivery systems that are meant to deliver medicines locally to the sick location. As a result, a variety of fabrication procedures were used to make these biopolymeric drug delivery systems, each with its own set of benefits and limitations.

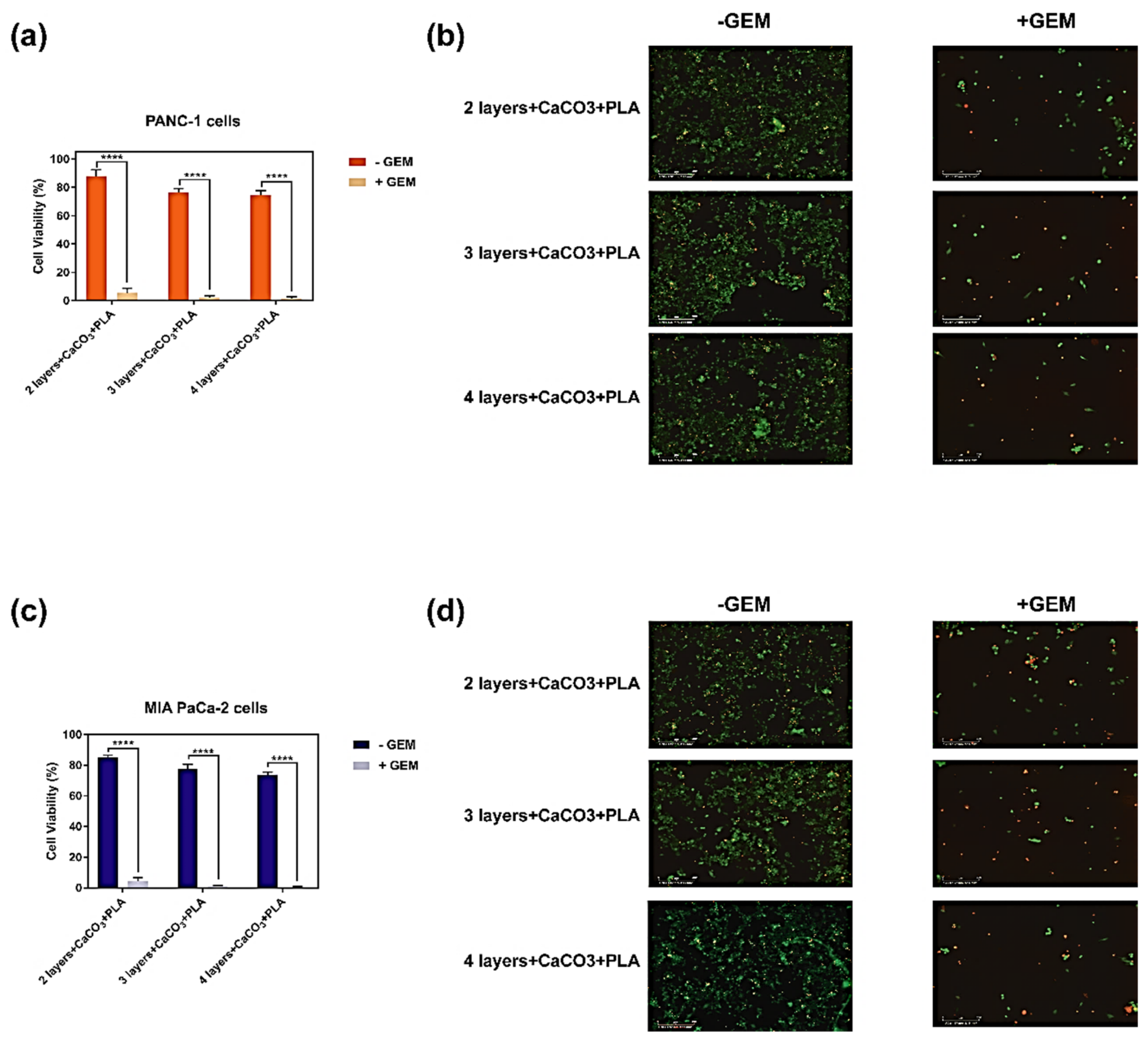

In vitro biocompatibility of PLA coated 3D printed coaxial patches containing CaCO3 either without Gemcitabine (− GEM), or loaded with Gemcitabine (+ GEM). (a) MTS cell viability assay of PANC-1 human pancreatic adenocarcinoma cells when treated with the patches for 72 h. (b) Corresponding live/dead cell staining of treated PANC-1 human pancreatic adenocarcinoma cells. (c) MTS cell viability assay of MIA-PaCa-2 human pancreatic adenocarcinoma cells when treated with the patches for 72 h. (d) Corresponding live/dead cell staining of treated MIA-PaCa-2 human pancreatic adenocarcinoma cells. Values are the mean (±SEM) of quadruplicate. **** p = 0.0001. Image Credit: Talebian, S., et al, Polymers

3D Printing Technologies to Cure Cancer

3D printing technologies, for example, provide significant advantages such as repeatability and the capacity to construct geometrically complicated structures. Furthermore, 3D printing works with a wide range of biopolymers, including hydrophobic thermoplastic polymers such as PCL and PLA with hydrophilic hydrogels (such as alginate, chitosan, and gelatine).

Fabricated 3D printed patches constructed from a blend of lactide and glycolide, as well as PCL loaded with fluorouracil, aiming at pancreatic cancer growth inhibition. As a result, it was discovered that the geometry (slant, latticed, or triangle) and the number of hidden layers had a direct impact on the fluorouracil release profile.

Furthermore, when tested in rats with subcutaneous pancreatic tumors, the patches were able to release it throughout a 4-week period and caused a substantial reduction in relative tumor growth when compared to empty implanted patches. In another case, 3D printed scaffolds were employed to administer Doxorubicin (DOX) locally to slow the development of breast cancer tumors.

3D Printed Hydrogel for Chemotherapy Medication

Researchers make 3D printed with a unique coaxial hydrogel patch to create a suitable platform for continuous administration of Gemcitabine (a chemotherapy medication). The center of these patches was made up of dopamine-modified alginate methacrylate filled with Gemcitabine, whereas the shell was made up entirely of alginate methacrylate.

The patches were then modified with a CaCO3 crosslinker as well as a PLA coating to aid in the drug's sustained release. As a result, the microstructural structure, tensile characteristics in both static and dynamic situations (mechanical testing and dynamic mechanical, respectively), and swelling behavior of the manufactured patches were investigated.

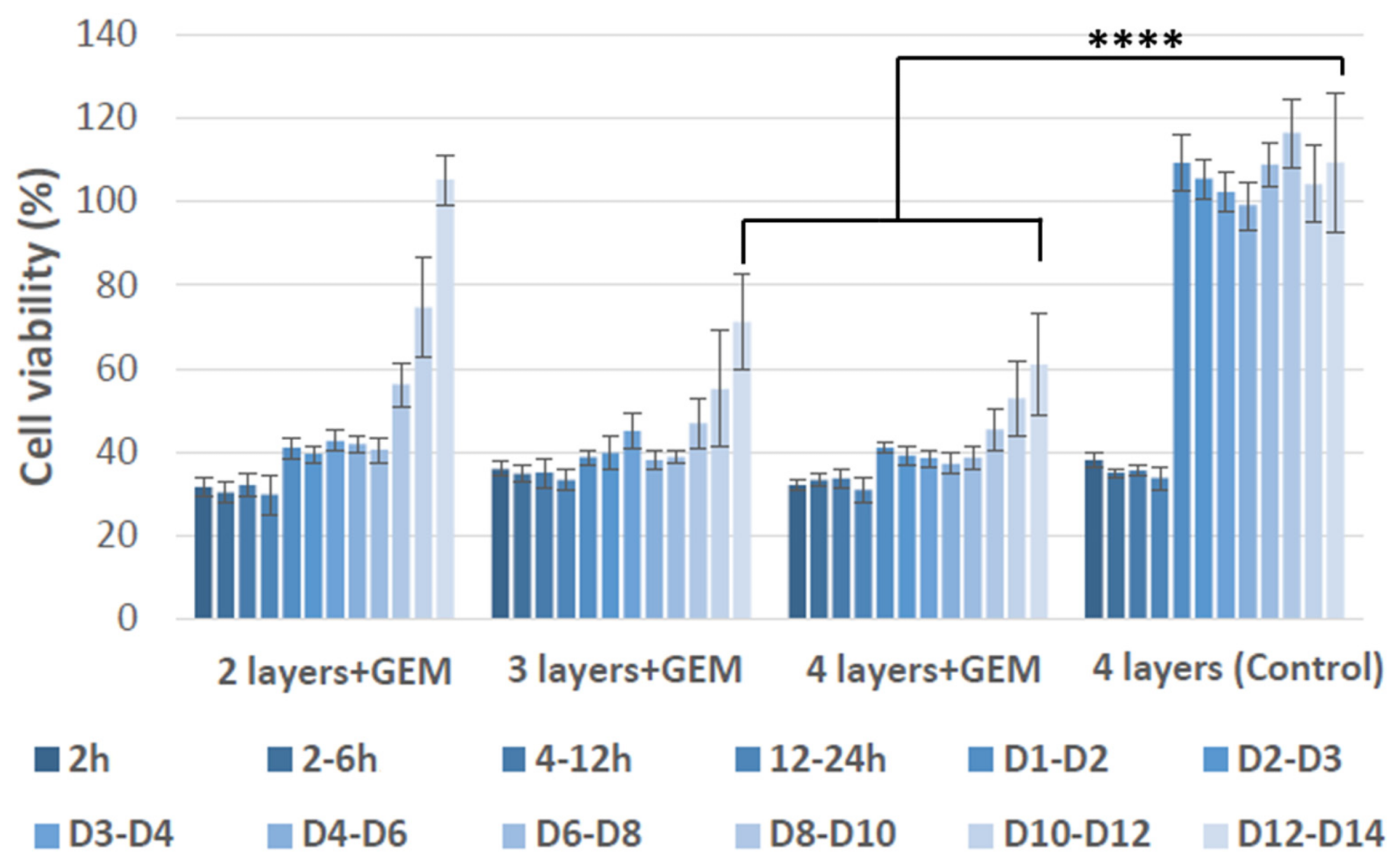

The therapeutic effect of PLA coated 3D printed coaxial patches containing CaCO3, with Gemcitabine (+GEM) or without Gemcitabine (control), on inhibition of MIA-PaCa-2 pancreatic cancer cell growth. Values are the mean (±SEM) of quadruplicate. D in the figure legend denotes days of treatment. **** p = 0.0001. Image Credit: Talebian, S., et al, Polymers

Result of the Research with Further Advancement

Furthermore, the anti-cancer efficacy of these patches was tested against pancreatic cancer tissues, including both vitro and in vivo. Ultimately, the suggested method for obtaining prolonged Gemcitabine discharge from 3D-printing hydrogel patches has been demonstrated to be successful, and with further improvement, these patches might be used as neoadjuvant or adjuvant therapy in cancer patients.

It shows that pulsatile release patterns may provide more effective therapies. Finally, these PLA-coated 3D printed patches might be employed as biocompatible implants for local administration of additional chemotherapeutics to sick locations in order to decrease tumors or prevent recurrence following excision.

Further research can be done by using other types of coating because PLA coating led to an optimal reduction in swelling of the patches. The crosslinker of CaCO3 can also be modified to receive the best result of 3D printed hydrogel patches.

References

Talebian, S., et al. (2021). 3D-Printed Coaxial Hydrogel Patches with Mussel-Inspired Elements for Prolonged Release of Gemcitabine. Polymers 2021, 13(24), 4367; Published Online: 13 December 2021. https://www.mdpi.com/2073-4360/13/24/4367

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.