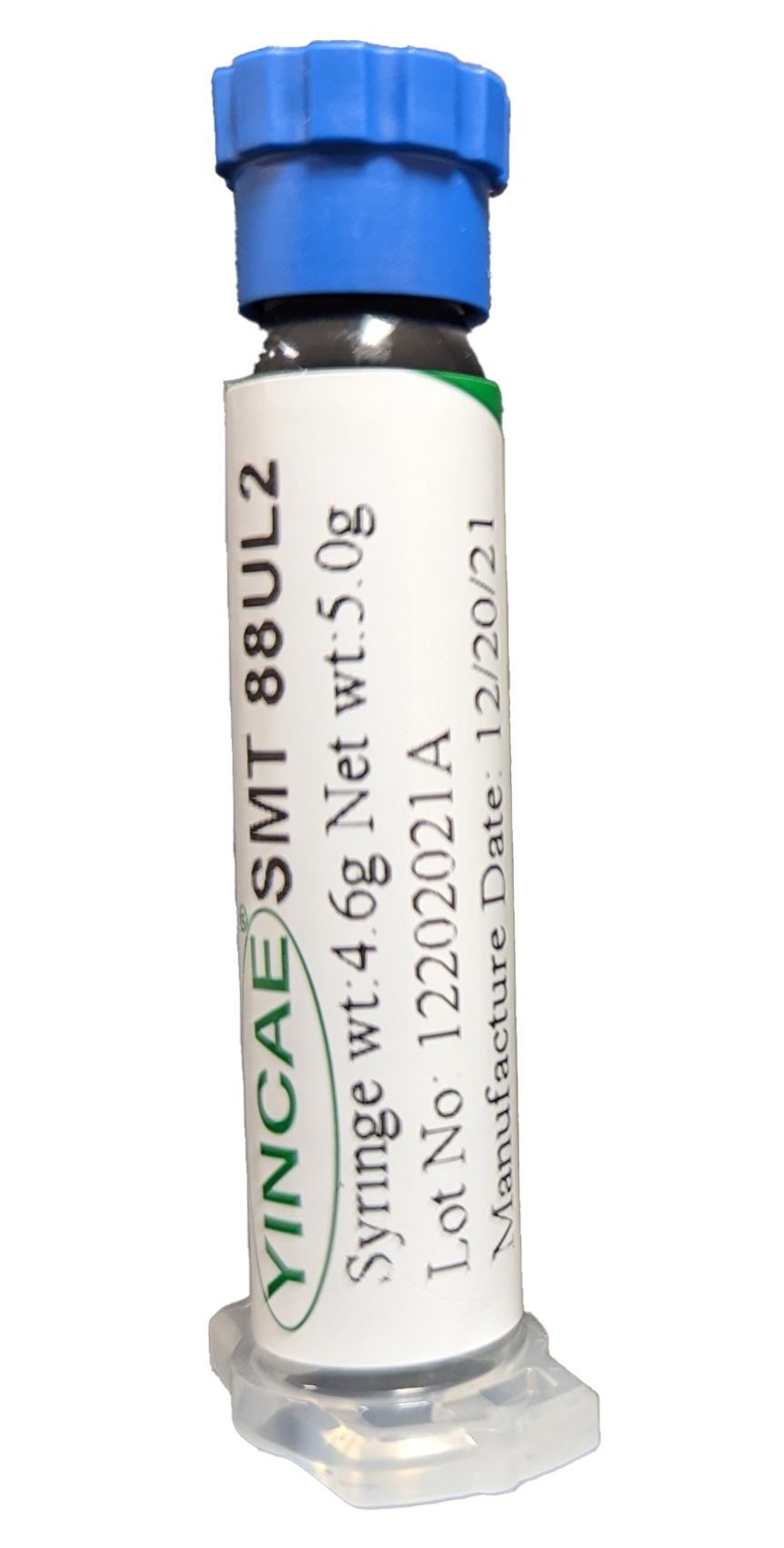

YINCAE is excited to announce that we have developed and upgraded SMT 88UL to SMT 88UL2, a fully flux residue compatible, room temperature fast flow and easily reworkable underfill.

Image Credit: YINCAE Advanced Materials

The compatibility of underfill and flux residue has long been a traditional issue in the electronic industry. This compatibility issue normally leads to underfill flow issue, underfill voids, underfill delamination and solder extrusion during the double reflow process and automotive application. Typically, it is too costly to clean the flux residue in SMT assembly. SMT 88UL2 is designed to be fully compatible with the flux residues of almost all solder paste from major manufacturers. SMT 88UL2 can fast flow into any gap size (less than 1) at room temperature and fast cure at lower temperatures without any flow and void issues eliminating cleaning flux residue. Our SMT 88UL2 can withstand multiple 260C reflow process without any delamination, solder extrusion and solder ball issues without cleaning flux residue. It has demonstrated excellent drop and thermal cycling performance.

This material can be used as an underfill for flip chip, chip scale package, ball grid array devices, package on package, and land grid array applications. It is also suitable for bare chip protection in a variety of advanced packages such as memory cards, chip carriers, hybrid circuits and multi-chip modules. It is designed for high production and an environment where process speed and thermal dissipation are key concerns.

For more information on YINCAE’s SMT 88UL2 underfill, or to learn more about the YINCAE product range, please email us at: [email protected]. You can also find more information by visiting our website at: www.yincae.com