In a study published in the journal Food Packaging and Shelf Life, researchers from Switzerland investigated the use of palladium-based oxygen scavengers to improve the shelf life of bakery products.

Study: Application of palladium-based oxygen scavenger to extend the mold-free shelf life of bakery products, Image Credit: JakubD/Shutterstock.com

Modified Atmosphere Packing

Staling and microbiological development are the primary factors limiting the shelf life of bakery products. The self-life of bakery products is determined by the type of ingredients used and the packaging conditions. Without antimicrobial preservatives and extra packaging technologies (modified environment packaging or cleanroom technology), bread has a shelf life of around 2–3 days.

It has been demonstrated that the majority of microbiological deterioration of bakery items is caused by molds such as penicillium spp. and aspergillus niger. Molds are responsible for generating off-flavors, and the production of mycotoxins and allergic chemicals. Visible yeast growth (chalk molds) is also a significant reason for bread damage.

Consumers expect bakery items to have a longer shelf life and be free of synthetic preservatives. This is accomplished by using modified atmosphere (MA) packing. The MA is mainly composed of N2 and CO2 atmosphere. CO2 and N2 in MA are antibacterial and reduce microbial growth.

MA packaging can minimize the amount of oxygen in the headspace, which is required for aerobic microbe growth in bread. However, MA packaging may be unable to lower oxygen concentrations to deficient levels on an industrial scale. Innovative packaging technologies (oxygen scavengers and MA packaging) can reduce residual oxygen in the headspace, extending the shelf life of bakery items and obviating the need for antimicrobial preservatives.

In this study, researchers investigated the application of the proposed palladium-based catalytic system for oxygen removal and its effect on mold formation on par-baked buns, toast bread slices, and gluten-free bread slices.

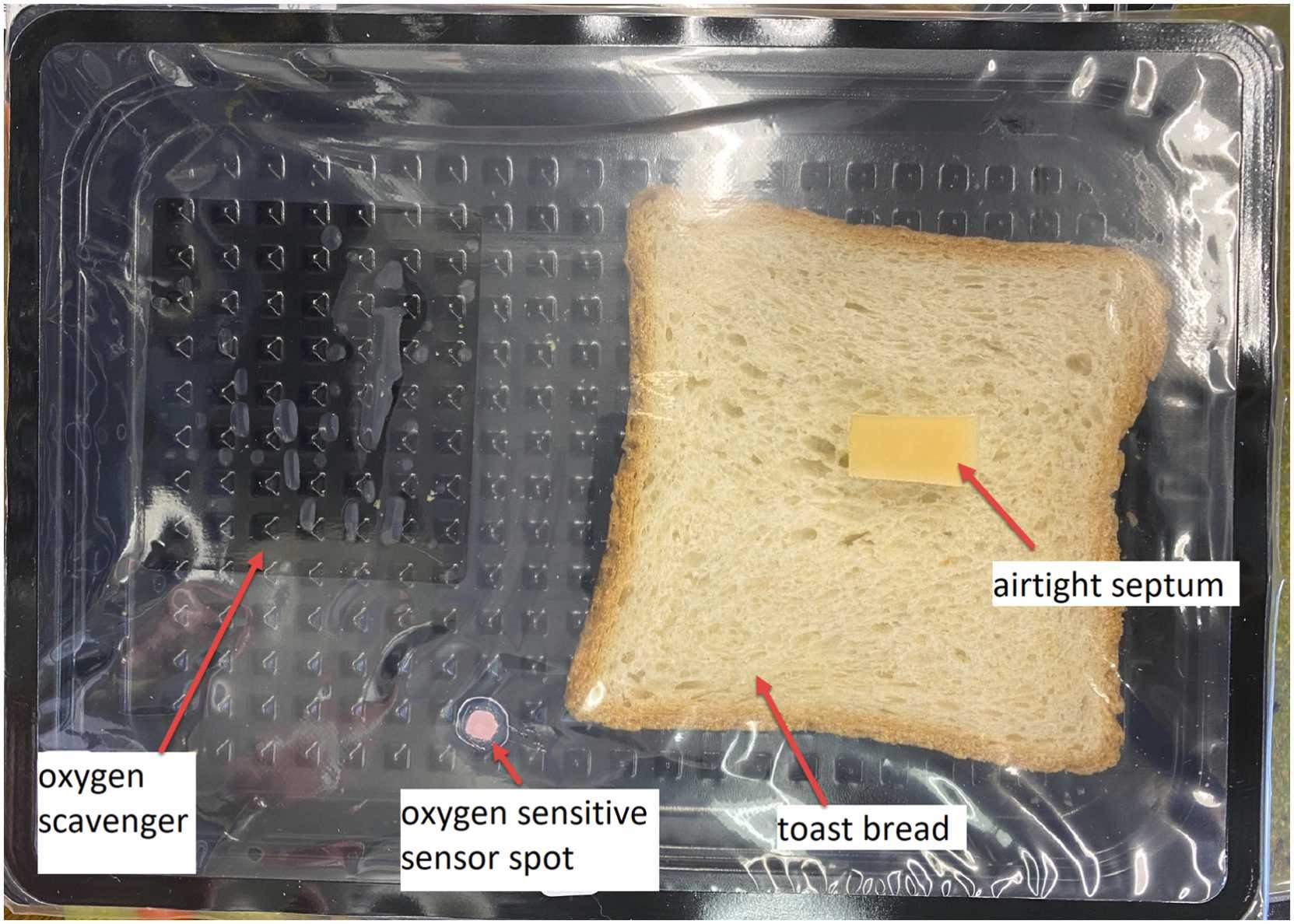

Experimental set-up to evaluate the influence of palladium-based oxygen scavenger on the mold free shelf life of bakery products. High barrier tray containing the oxygen scavenger (catalytic system based on palladium) attached on the lidding film, toast bread slice, airtight septum through which the bakery sample was inoculated and an oxygen sensitive sensor spot. Image Credit: Nadine Rüegg et al., Food Packaging and Shelf Life

Methodology

The researchers developed the catalytic system based on palladium (CSP) by vacuum-depositing palladium on a PET/SiOx film using magnetron sputtering technology, followed by cutting CSP into labels. It was ensured that the active side of the CSP was directed toward the headspace of the bakery item package, away from the packed food.

To obtain sporulation, aspergillus niger (ATCC 16404) was cultivated on malt agar plates made of malt extract and agar for 12 days at 25 °C in the darkroom.

For the study, the researchers used par-baked buns, toast bread, and par-baked gluten-free bread. Par-baked buns were produced with wheat flour, tap water, margarine, backing agent, salt, and yeast. Toast bread was produced with wheat flour using tap water, backing agent, salt, rapeseed oil, and yeast. Par-baked buns and toast bread were defrosted at 5 °C for 24 hours before packaging. Post preparation of par-baked buns and toast bread was packed in bakery-type packaging. Par-baked gluten-free bread (preservatives free) was purchased from a German industrial bakery.

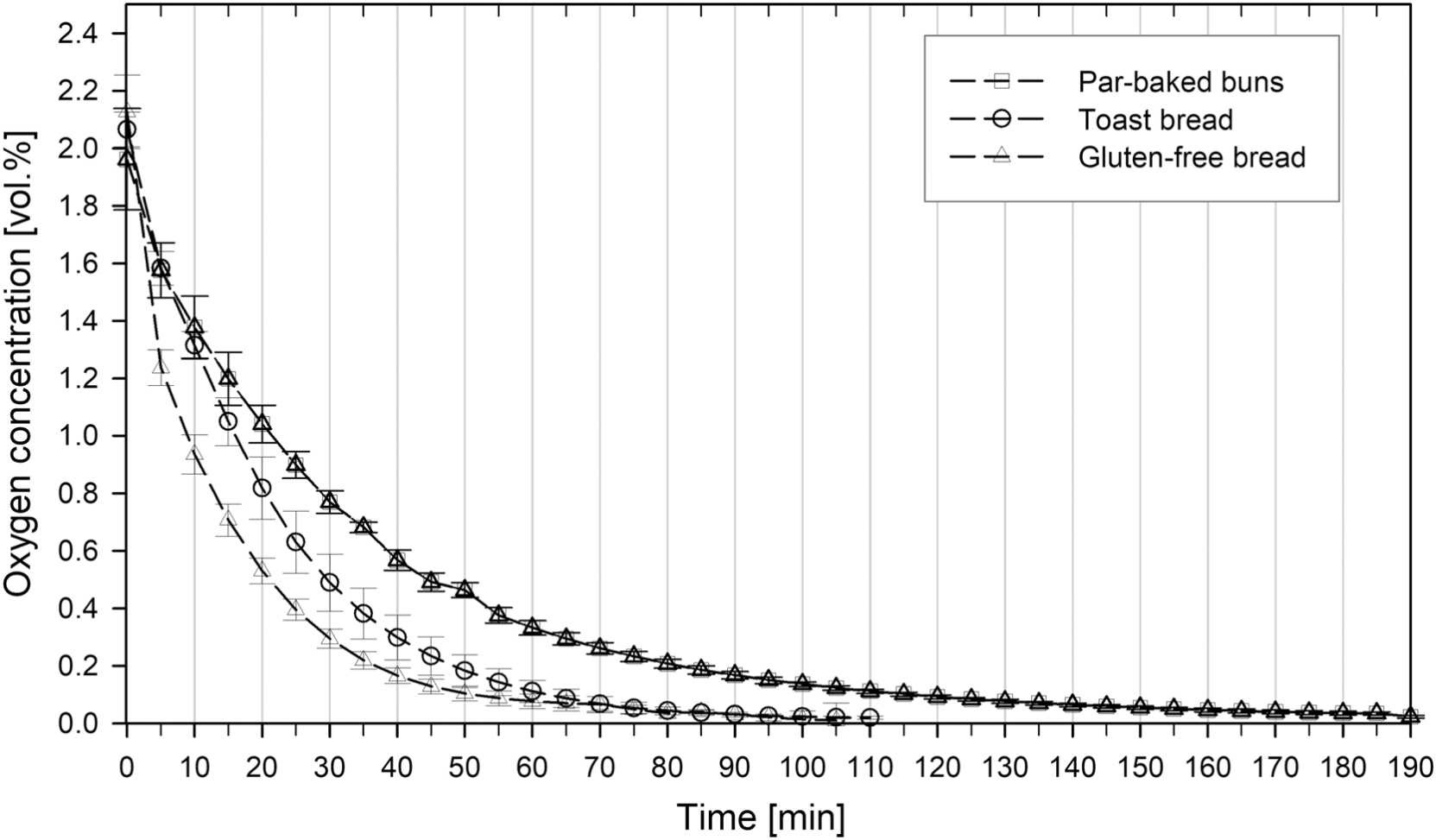

Reduction in headspace oxygen concentration of par-baked buns, toast bread slices and gluten-free bread slices packed under modified atmosphere (93 vol.-% CO2, 2 vol.-% O2 and 5 vol.-% H2) with CSP and stored at 25 ± 1 °C. Headspace volume (HSV) was for par-baked buns ~410 cm3, toast bread slices ~460 cm3 and gluten-free bread slices ~490 cm3. Mean values ± standard deviation (n = 3). Image Credit: Nadine Rüegg et al., Food Packaging and Shelf Life

Results

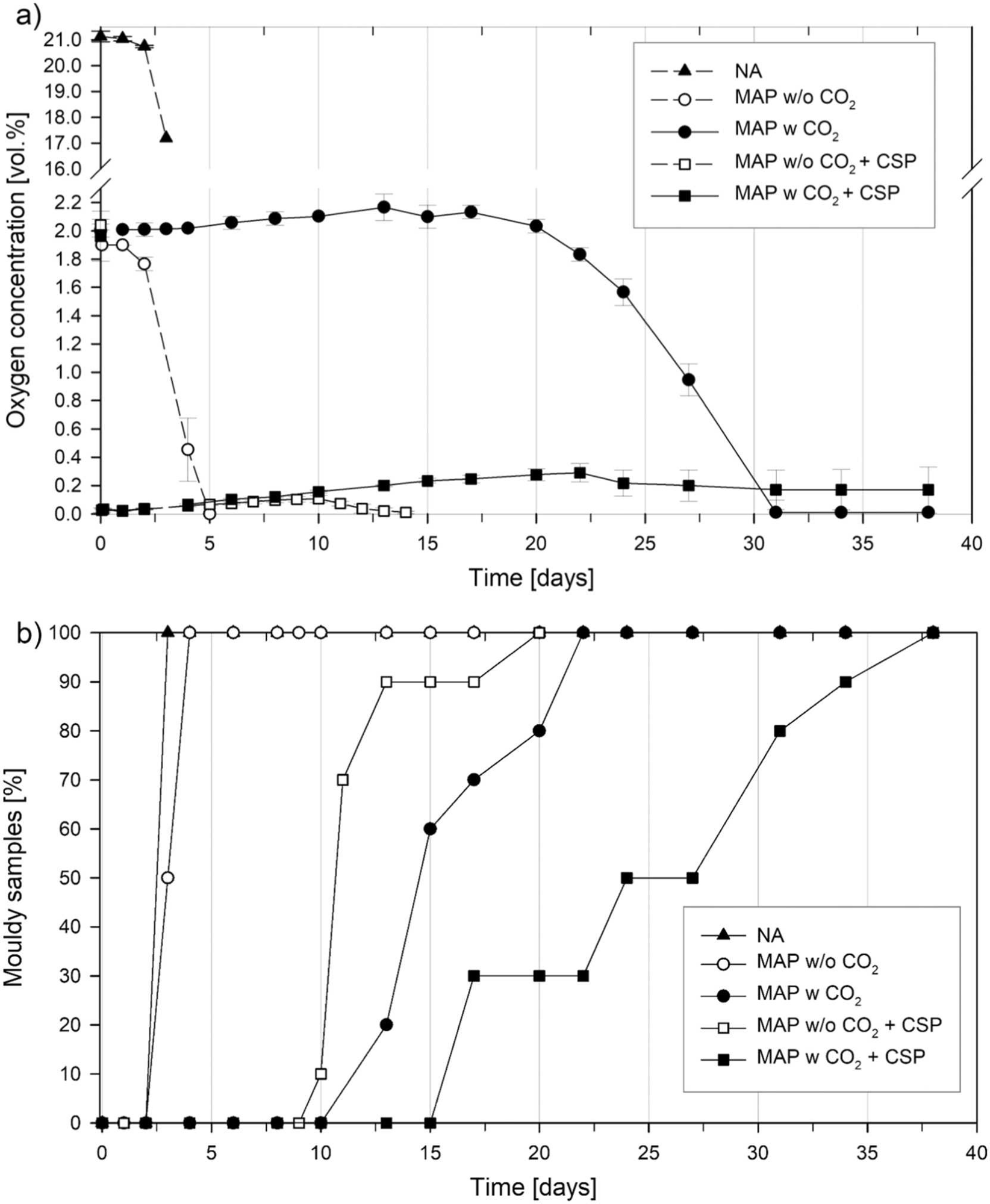

According to this study, the mold-free shelf life of par-baked buns, toast bread slices, and gluten-free bread slices packaged under typical atmospheric conditions with no preservatives is around 1–2 days. After 2–3 days, mold development was found on all products packed under standard atmosphere and MA without CO2, and CSP.

The addition of CO2 to MA increased the mold-free self-life (MFSL) by 8–10 days, 16–18 days, and 3–4 days, respectively, for par-baked buns, toast, and gluten-free bread. Within 105–190 minutes of using CSP with MA, the oxygen content in the headspace was reduced for all bread goods, resulting in an additional 3–9 days of MFSL for bakery products.

Change in headspace oxygen concentration of par-baked buns (a) and growth of spoilage molds on par-baked buns (b) packed under normal atmosphere (NA), modified atmosphere with 93 vol.-% N2, 5 vol.-% H2, 2 vol.-%O2 (MAP w/o CO2) or modified atmosphere with 93 vol.-% CO2, 5 vol.-% H2, 2 vol.-%O2 (MAP w CO2) with and without the catalytic system based on palladium (CSP) for 38 days at 25 °C. Mean values ± standard deviation (a: n = 3, b: n = 10). Image Credit: Nadine Rüegg et al., Food Packaging and Shelf Life

Conclusion

To extend the mold-free shelf life of packaged bakery products, the oxygen initially present in the bakery container should be removed. Additionally, the oxygen emitted by the product during storage and diffusion through the packing material must also be removed. Oxygen removal could be accomplished by combining the CSP with another oxygen scavenger system, which is capable of long-term oxygen absorption. Effective oxygen removal from bakery product packaging enables the elimination of antimicrobial preservatives and aids in the development of clean label products. However, additional expenditures involved with the employment of two oxygen scavengers are a considerable economical factor.

A similar analysis using spoilage yeasts which could still lead to spoilage of bakery products even with the application of oxygen exclusion technologies needs to be carried out in the future. In addition, a combined study can also be conducted using a variety of yeast and bacterial to understand the spoilage of other bakery products.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Nadine Rüegg, Bettina Röcker, Selçuk Yildirim, Application of palladium-based oxygen scavenger to extend the mold-free shelf life of bakery products, Food Packaging, and Shelf Life, Volume 31, 2022,100771,ISSN22142894, https://www.sciencedirect.com/science/article/pii/S2214289421001393?via%3Dihub