Electric vehicles (EVs) require cheaper, more effective and longer-lasting batteries that will not burst while in use or pollute the environment if they are to become widely popular. The scientists at the Georgia Institute of Technology believe that they have identified rubber — a common material — as a possible and beneficial alternative to the existing lithium-ion batteries in rubber.

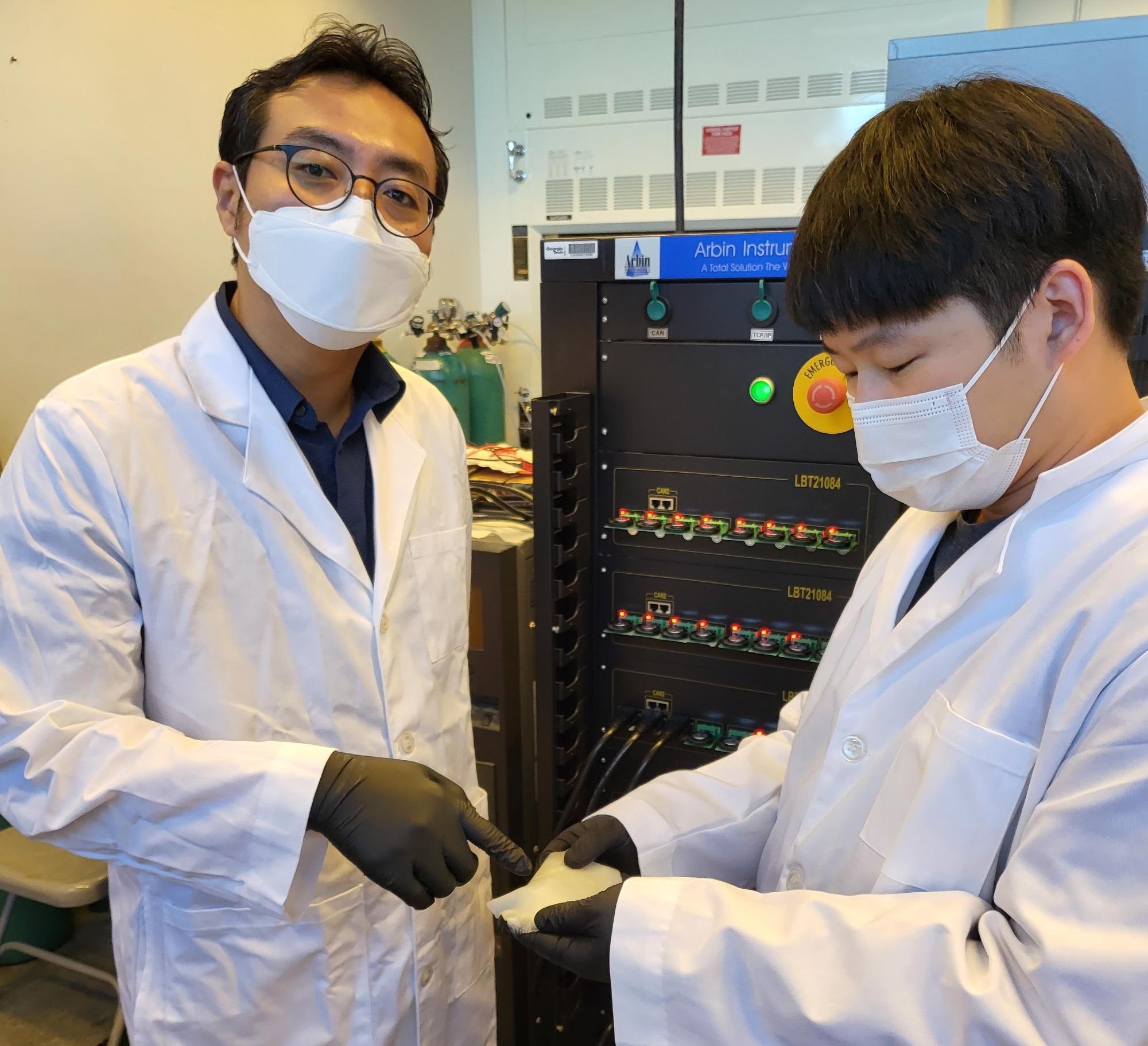

Prof. Seung Woo Lee (left) and Michael J. Lee (right) have demonstrated a more cost-effective, safer solid polymer electrolyte (rubber material) for all-solid-state batteries. Image Credit: Georgia Institute of Technology.

Prof. Seung Woo Lee (left) and Michael J. Lee (right) have demonstrated a more cost-effective, safer solid polymer electrolyte (rubber material) for all-solid-state batteries. Image Credit: Georgia Institute of Technology.

Due to their enhanced mechanical properties, elastomers, or so-called synthetic rubbers, are broadly used in commercial products and modern applications such as wearable electronics and soft robotics. The scientists determined that when devised into a 3D structure, the material intervened as a superhighway for rapid lithium-ion transport with excellent mechanical tenacity, leading to longer rechargeable batteries that can go quite far.

The study performed in partnership with the Korea Advanced Institute of Science and Technology was published in the journal Nature.

A liquid electrolyte moves ions in conventional lithium-ion batteries. Moreover, the battery is highly unstable — even minor damage can cause electrolyte leakage, resulting in a fire or an explosion. The industry has been compelled to consider solid-state batteries, which can be made from inorganic ceramic material or organic polymers due to safety concerns.

Most of the industry is focusing on building inorganic solid-state electrolytes. But they are hard to make, expensive, and are not environmentally friendly.

Seung Woo Lee, Associate Professor, George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology

Lee is also part of a group of researchers who discovered a rubber-based organic polymer that outperforms other materials.

Solid polymer electrolytes remain popular due to their low production costs, gentle nature and non-toxicity. Besides this, conventional polymer electrolytes lack the ionic conductivity and mechanical stability required for solid-state battery performance.

Novel 3D Design Leads to Jump in Energy Density, Performance

Using rubber electrolytes, engineers from Georgia Tech have fixed common issues like slow lithium-ion transport and poor mechanical properties. The ability of the material to form a three-dimensional (3D) interconnected plastic crystal phase inside the sturdy rubber matrix was a major advancement. Thus, increased ionic conductivity, excellent mechanical properties and electrochemical stability have all been achieved as a result of this one-of-a-kind structure.

This rubber electrolyte can be created through a basic polymerization process at relatively low temperature, resulting in sturdy and sleek integrations on the surface of electrodes. Such special properties of rubber electrolytes help prevent the formation of lithium dendrite and permit faster moving ions, thereby allowing solid-state batteries to operate reliably even at room temperature.

Rubber has been used everywhere because of its high mechanical properties, and it will allow us to make cheap, more reliable, and safer batteries.

Seung Woo Lee, Associate Professor, George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology

Michael Lee, a mechanical engineering graduate researcher also stated, “Higher ionic conductivity means you can move more ions at the same time. By increasing specific energy and energy density of these batteries, you can increase the mileage of the EV.”

Currently, scientists are investigating ways to enhance battery performance by improving cycle time and reducing charging time via advanced ionic conductivity. As of now, their efforts have resulted in a two-fold increase in cell performance or flow time.

The research could benefit Georgia’s reputation as an EV innovation hotspot. As part of its ongoing partnership with the institute to develop succeeding solid-state batteries that are secure and more power-dense compared to regular Li-ion batteries, SK Innovation — a global energy and petrochemical company — is funding an additional study into the electrolyte material.

SK Innovation recently started building a new EV battery plant in Commerce, Georgia, which is expected to produce 21.5 gigawatt-hours of lithium-ion batteries annually by 2023.

All-solid-state batteries can dramatically increase the mileage and safety of electric vehicles. Fast-growing battery companies, including SK Innovation, believe that commercializing all-solid-state batteries will become a game-changer in the electric vehicle market.

Kyounghwan Choi, Director, SK Innovation

“Through the ongoing project in collaboration with SK Innovation and Professor Seung Woo Lee of Georgia Tech, there are high expectations for rapid application and commercialization of all-solid-state batteries,” added Choi.

Journal Reference:

Lee, M. J., et al. (2022) Elastomeric electrolytes for high-energy solid-state lithium batteries. Nature. doi.org/10.1038/s41586-021-04209-4.