Oil spills are a frequent occurrence globally. There have been many technologies employed over the years to clean them up and mitigate damage their environmental impact. Now, a team writing in Materials has developed a new sorbent based on graphite and evaluated its potential use for this purpose.

Study: A Novel Graphite-Based Sorbent for Oil Spill Cleanup. Image Credit: dimitris_k/Shutterstock.com

Tackling Oil Spills

An oil spill is the intentional or accidental release of liquid hydrocarbons (oil) into the environment. Whilst they vary in entity and type, stemming them is challenging, and they cause catastrophic environmental harm.

The impact of large-scale spills can be long-term, taking years to remediate. Whilst the harm caused by these large-scale environmental disasters is obvious, the impact of more minor spills cannot be underestimated. They can lead to contamination of soil and groundwater, causing long-term damage to environments.

Whilst growing social awareness of environmental harm has led to government policies that have reduced the instance of catastrophic oil spills, there have still been events in recent years which have had a devastating impact on fragile ecosystems. Minor spills, whilst not reported on as thoroughly in the news, happen regularly across the world.

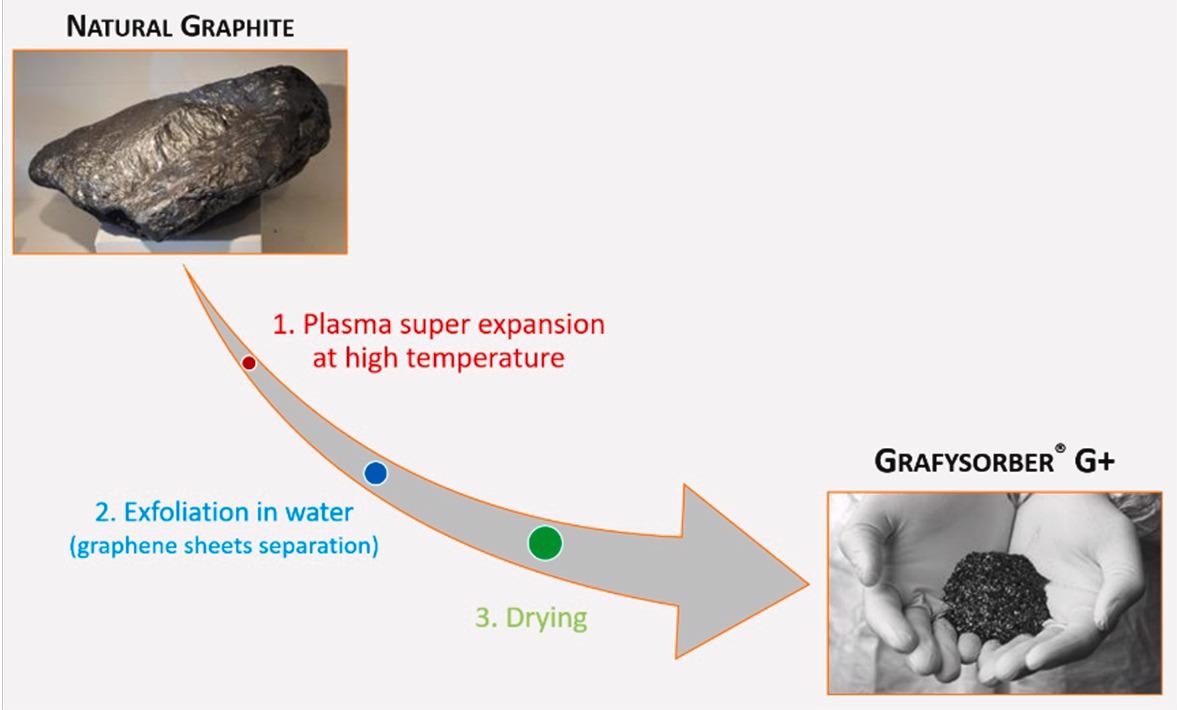

The production process of Grafysorber® G+. Image Credit: Vocciante, M et al., Materials

Sorbents

Adsorption is a simple and effective approach for the removal or organic and inorganic contaminants from aqueous environments. The possibility of exploiting low-cost adsorbent materials from waste has environmental benefits as well regarding the circular economy concept and reducing hazardous waste discharge. In recent years, adsorbent materials have become the focus of research in oil spill clean-up strategies, with the added benefit of facilitating increased oil recovery.

Sorbents are hybrid systems of contaminant removal and many materials have been explored for use as sorbents. These include organic materials such as tree bark, wool, straw, and human hair and animal fur, inorganic materials such as alumina, and synthetic compounds such as polymers. The requirements which must be met for a sorbent include biodegradability, low cost, good selectivity, low retention, and high absorption capacity.

Natural Vs Synthetic Sorbents

Natural and synthetic sorbents have advantages and disadvantages. What natural sorbents lack in efficiency and mechanical and practical characteristics they make up for in cost, availability, and biodegradability. Synthetic sorbents such as polypropylene have better performance overall but have drawbacks such as reduced biodegradability, landfill expenses, and difficulty in recovering adsorbed oil. Alternatives that meet all these criteria are needed.

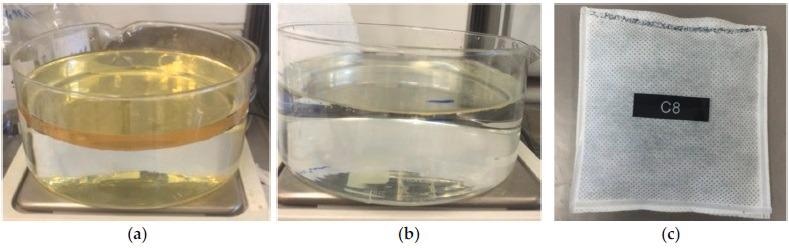

(a) Initial condition of test 2; (b) Initial condition of test 3; (c) Pillow used for laboratory tests. Image Credit: Vocciante, M et al., Materials

Expanded Graphite as a Sorbent Material

The study published in Materials has explored the use of expanded graphite for this purpose. Inagaki and Toyoda first demonstrated the effectiveness of the material, and in recent years it has been the subject of research exploring its properties and strategies to improve it. Research has led to the development of Grafysorber® G+, an oleophilic/hydrophobic material with enhanced adsorption capacity. This innovative material was the focus of the study.

Developed by Directa Plus in Italy, the material’s characteristics make it a promising alternative to conventional expanded graphite materials. The structure of the material consists of weakly-bound graphene layers in an accordion-like shape, and the material is completely additive-free. It can be used in a loose form for treating industrial wastewater, or in confined shapes such as booms and cushions for oil spill remediation. It can easily be removed and handled once saturated with contaminants.

The novel nature of the material means that, currently, there are relatively few studies on its characteristics and adsorption capabilities for different hydrocarbon compounds. The study published in Materials has used laboratory investigations to provide a deeper understanding of this material’s performance and properties to improve its efficient use in field applications.

Three types of tests were performed: an evaluation of the material’s performance under static conditions with small amounts of oil and material, larger-scale tests in a 1 x 5 m wave tank, and contaminant tests in the laboratory. The graphene material’s performance was evaluated by comparing it to polypropylene flakes. Different oils (crude oil, diesel, and kerosene) were evaluated. Additionally, the authors investigated the possibility of recovering oil and materials via mechanical squeezing.

Pilot tank device for oil-adsorbent capacity testing of Grafysorber® G+ and PP booms in dynamic conditions. Image Credit: Vocciante, M et al., Materials

Results of the study indicated that the absorption capacity was up to 5x higher than polypropylene flakes. G+ absorbed 120-187 times its weight over 4 use cycles, compared to 20-33 times for polypropylene under laboratory conditions. Similar results were observed in tank tests. Better hydrophobic properties, absorption capacity, and faster absorption kinetics were observed.

Reusability of G+ was demonstrated, albeit with loss of capacity. Recovery via squeezing shows limitations, possibly due to mechanical stress and damage to the material’s structure. The authors identified this as a target of further experimentation. Moreover, the authors identified advantages in terms of cost and sustainability. However, it must be stressed that this experiment was under ideal laboratory conditions, so the real advantage of the material should be assessed on a case-by-case basis.

Further Reading

Vocciante, M et al. (2022) A Novel Graphite-Based Sorbent for Oil Spill Cleanup [online] Materials 15(2) 609 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/2/609

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.