In a recent study published in the journal Materials, researchers from the Czech Republic developed hybrid prepreg tapes (rectangular cross-section) from glass multifilament roving (circular cross-section) and epoxy matrices using controlled mechanical spreading technology.

Study: Hybrid Prepreg Tapes for Composite Manufacturing: A Case Study. Image Credit: Gorodenkoff/Shutterstock.com

The researchers characterized the strength distribution of the glass fiber, roving, and tape using the three parameters’ Weibull distribution model and the quantile-quantile plot-based exploratory data analysis tool. The resulting glass fiber-epoxy tape composite demonstrated improved mechanical tensile properties and adaptivity to complex robotic winding.

Glass Fiber-Based Hybrid Prepreg Tapes

Commercial glass has a high hardness between 5.5-7 Mohs and high tensile strength between 2400-4500 MPa in its fiber form. This makes glass fibers cheap and robust reinforcement fillers in many composite materials which demand high strength, thermal insulation, acoustic insulation, electrical insulation, and corrosion resistance in various fields such as automobile, aerospace, marine, sporting, and constructions.

Most commonly, thermoset resins are used as a binder to ensure the cohesion of the composite, and distribute and dampen the impacts or stresses to protect the composite from the environment.

Robotized winding by using hybrid tapes (developed at TUL). Image Credit: Venkataraman, M et al., Materials

The glass multifilament rovings are a set of unidirectional glass fibers. These rovings are spread into a tape form with a rectangular cross-section followed by interweaving into prepregs mats and then pre-impregnated with a thermoset resin. The rectangular cross-section (uniform thickness) of the prepreg tape evenly distributes the tensile stress and absorbs the impact stress more effectively. The more the glass fiber filaments are parallel, and the higher the close packing, the higher the strength of the composite.

About the Study

In this study, researchers fabricated hybrid prepreg tapes from glass multifilament rovings comprised of aluminosilicate E-glass fibers and an epoxy matrix consisting of a mixture of acrylate polymers and epoxy-silane, using controlled mechanical spreading technology.

The obtained spread tow tapes (STT) were coated with a commercial epoxy resin and pre-cured at 80 ℃ for 24 hours in the presence of a catalyst. Finally, the epoxy cured STT were cross-winded on a paper roll to obtain the prepreg sheet. The facile spreading process had a limited honeycomb arrangement of fibers in the roving cross-section, and in that close honeycomb structures, the filaments were arranged in hexagonal concentric layers.

Furthermore, for a fixed filament fineness and corresponding filament diameter, the spread tow had the same shape characteristics as tow. The microstructures of the glass fiber, roving, and tape were studied using scanning electron microscopy (SEM) and the corresponding strength distribution was analyzed using the three parameters’ Weibull distribution model and the quantile-quantile plot-based exploratory data analysis tool.

Observations

The SEM images revealed that the tapes were approximately rectangular in cross-section and were slightly undulating, whereas the rovings were slightly wavey and the straps were straight.

The quantile-quantile (Q-Q) graph for normal distribution indicated differences in the lower and upper tail regions from the assumption of normality. They assumed that the glass filaments broke first (i.e. the glass filaments have lower breaking elongation than matrix phase), which assisted in predicting tape strength.

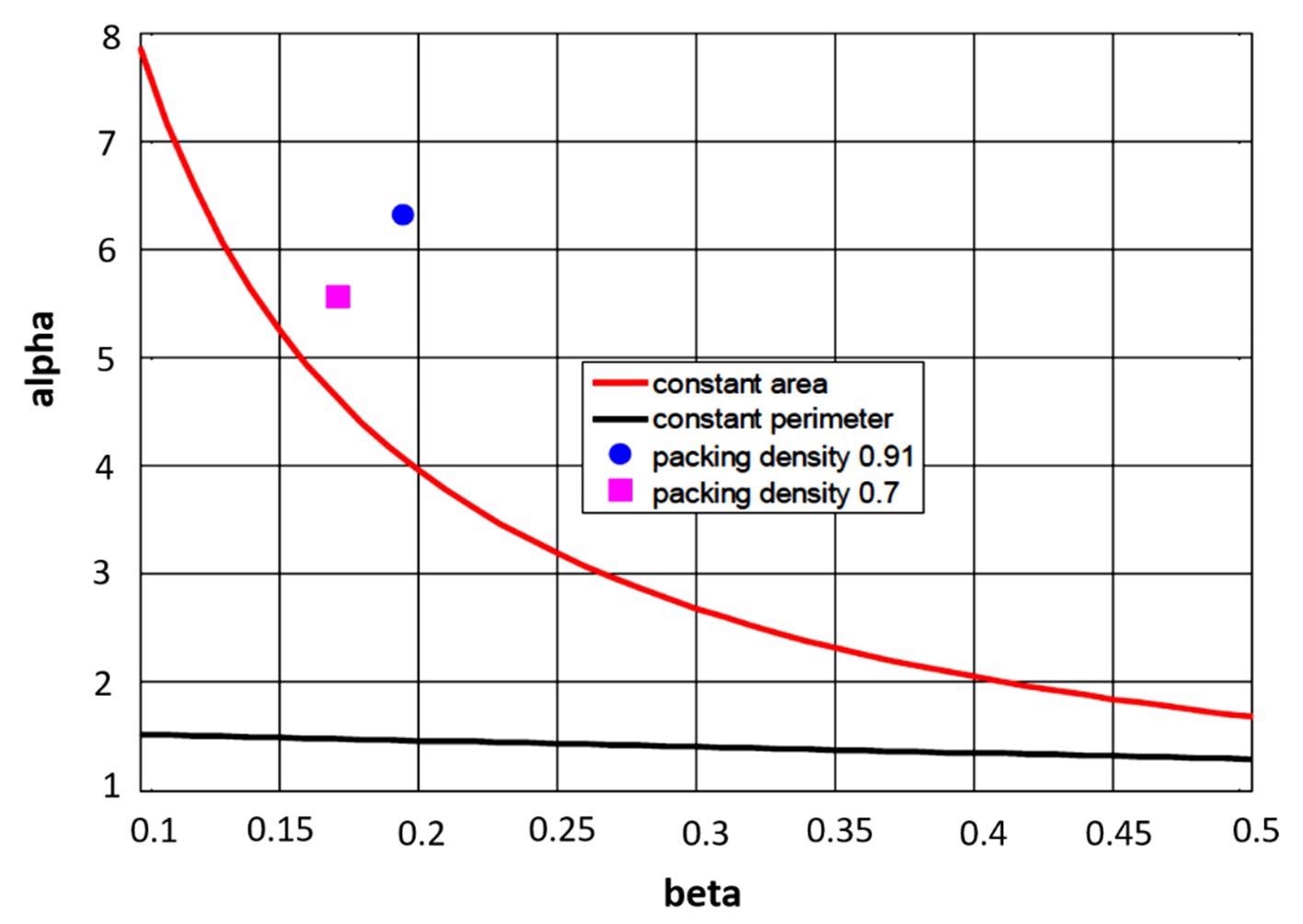

Dependence of tape width on thickness under different assumptions. Image Credit: Venkataraman, M et al., Materials

The three Weibull distribution parameters, namely A (the shift parameter), B (the scale parameter), and C (the shape parameter) were positive. Moreover, the non-iterative method based on the Weibull moments was more reliable than the iterative non-zero threshold A approach. Also, the average strength of spread tow was higher than simple tow, indicating the strength in the composite exceeded the strength of the strongest component. The mean predicted strength was 1.1835 GPa with a standard deviation of 0.0117 GPa.

Conclusions

In this study, researchers fabricated hybrid prepreg tapes with uniform rectangular cross-section from aluminosilicate E-glass fibers multifilament roving and acrylate polymers and epoxy-silane-based thermoset epoxy matrix using controlled mechanical spreading technology. The STT tapes were closely packed, evenly spaced along with the tape, and uniformly coated by the epoxy resin, which imparted high impact strength to the desired rectangular cross-section.

Further, the fiber strength distribution was successfully predicted by the three parameters A, B, and C of the Weibull distribution model and Q-Q normal distribution plot. The obtained strength of the hybrid prepreg had a high mean value of 1.1835 GPa with a standard deviation of 0.0117 GPa. Hence, this STT hybrid prepreg tape can be used in robotic winding, which requires high mechanical tensile properties.

Reference

Venkataraman, M., Militký, J., Samková, A., Karthik, D., Křemenáková, D., Petru, M., Hybrid Prepreg Tapes for Composite Manufacturing: A Case Study. Materials, 2022, 15, 619. https://www.mdpi.com/1996-1944/15/2/619

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.