High-strength bainitic steels possess properties that give them advantages over conventional steels. This has facilitated research into these materials for their application in several technological fields.

Study: Viewpoints on Technological Aspects of Advanced High-Strength Bainitic Steels. Image Credit: Mr. Kosal/Shutterstock.com

The concept of these materials has been revisited in a study published in Metals with the aim of highlighting challenges and limitations with the materials and exploring further research and development directions.

What are Bainitic Steels?

Conventional bainitic steels contain elevated levels of cementite in their microstructures. Bainitic steels are formed through the process of isothermal holding. Bainitic steels have several morphologies, including lower-bainite, upper-bainite, and granular bainite. Depending on the treatment’s temperature, cementite occurs either within the bainitic ferrite plates (lower-bainite) or at their boundaries (upper-bainite.)

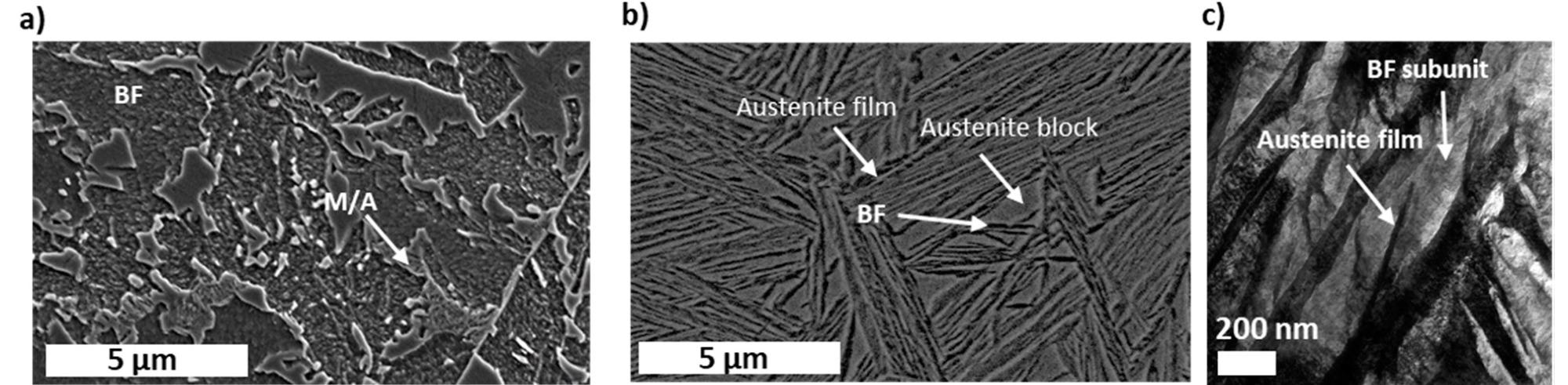

Granular bainite differs from lower- and upper-bainites. As opposed to conventional bainites, the microstructure of granular bainite lacks the presence of carbide. The final microstructure of granular bainite contains both austenite and marstenite (which is harmful) with high carbon content in solid solution. With the addition of silicon, carbide-free bainitic steels which possess different morphologies and with a higher carbon content can be manufactured due to the inhibition of cementite precipitation.

Secondary electron SEM images of Nital-etched metallographic surface of: (a) granular CFB obtained by continuous cooling (b) nanostructured bainite from a steel with 1C-2.5Si wt.% (among other elements) treated at 250 °C during 16 h (c) nanostructured bainite from a steel with 0.7C-1.4Si wt.% (among other elements) treated at 220 °C during supplementary time. BF stands for bainitic ferrite. Image Credit: Morales-Rivas, L, Metals

Material properties comparable to quenched and tempered steel can be achieved when isothermic heating is used until full bainitic transformation by inhibiting martensitic transformation upon final cooling. Recent research has indicated that isothermal holding can help to heal microcracks that are induced by cementite precipitation during quenching.

High-Strength Nanostructured Bainitic Steels

These types of bainitic steels are also referred to as super bainite and low-temperature bainitic steels. Silicon-based, they have high tensile strength (over 2000 MPa) and an elongation of up to 20%. These steels contain high amounts of carbon and silicon. One advantage of these steels is the lower starting temperature for bainitic conversion. Isothermal holding results in a very fine microstructure, with nanoscale bainite ferrite subunits.

In these steels, the bainitic phase is retained at room temperature due to the remaining austenite being rich in carbon in solid solution. Consequently, during final cooling, martensitic transformation is impeded, creating high-strength steel compared to conventional bainitic morphologies.

Other alloying elements are used during the manufacture of nanoscaled bainitic steels. These are manganese, chromium, and molybdenum. Other elements such as vanadium and aluminum are used depending on manufacturing processes and applications.

Advantages of these elements include lower bainitic and martensitic starting temperatures, improved hardening ability, and minimized chemical segregation issues. The ultra-high-strength values of these steels are due to the nanoscale size of bainitic ferrite features. Additionally, the material has enhanced ductility due to the presence of retained austenite.

![Figure 2 Mechanical performance of conventional steels and AHSS, adapted from [35,36,37].](https://www.azom.com/images/news/ImageForNews_57993_16430244965976865.jpg)

Mechanical performance of conventional steels and AHSS. Image Credit: Morales-Rivas, L, Metals

The Study

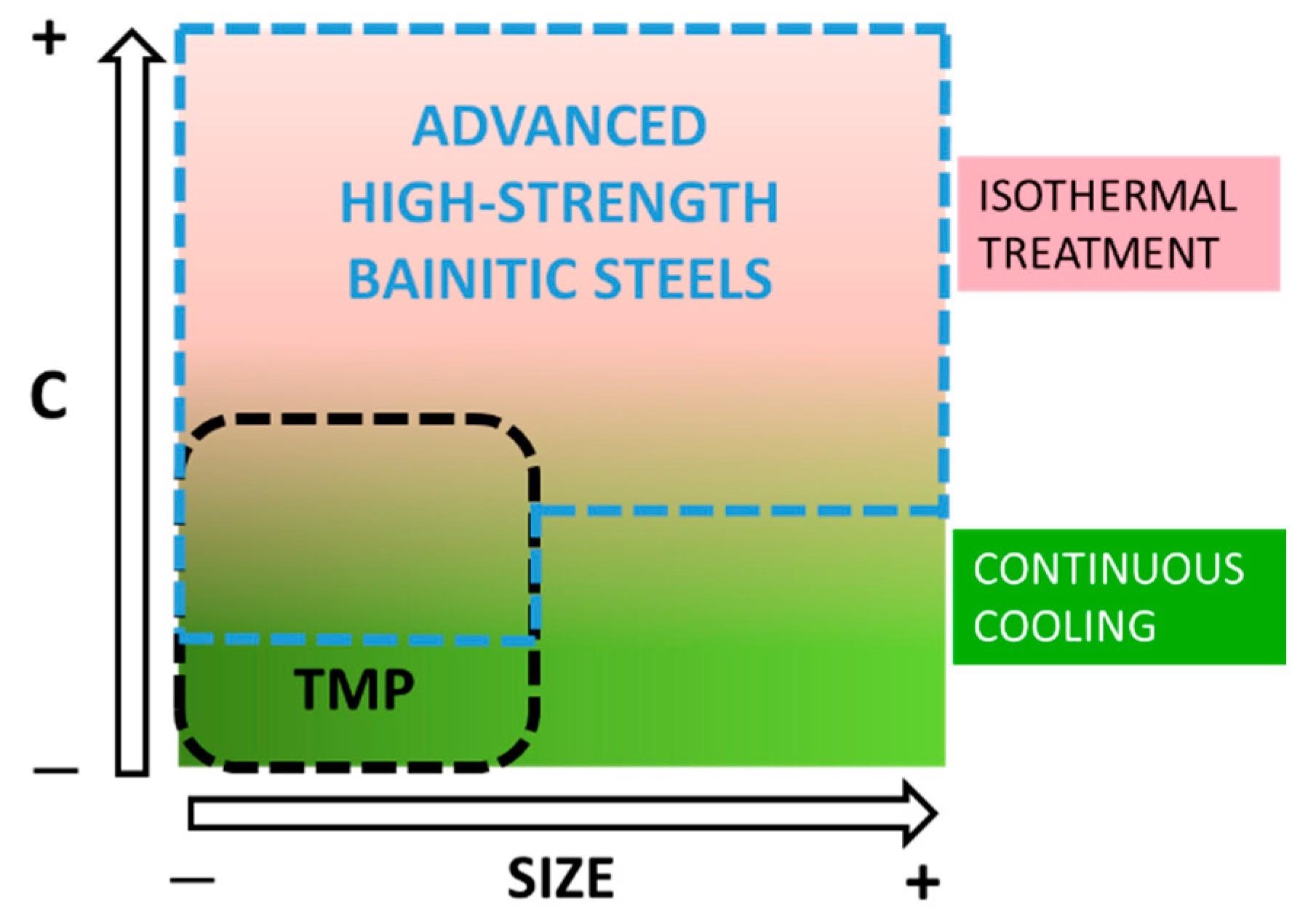

The paper published in Metals has investigated these high-strength nanostructured bainitic steels. The main part of the paper is divided into three parts which explore different carbide-free bainitic steels. These are high/medium carbon content nanostructured bainitic steels that have been formed at low temperatures with isothermal holding, medium/low carbon content steels manufactured as flat products, and medium-low carbon content steels typically manufactured as long products, which are formed using continuous cooling.

The main purpose of the study is to examine and highlight the main opportunities and limitations of advanced high-strength bainitic steels. The study examines different alloying and microstructural strategies for manufacturing high-strength bainitic steels.

One research direction highlighted in the study is the development of nanostructured bainitic bearing steel. This material has a surface layer of nanostructured bainite with the core consisting of tempered martensite. The nanocrystalline surface layer has a case-hardening effect which gives the tempered steel superior surface properties.

The wearing and rolling contact behaviors of this material are superior to conventional high carbon content chromium-bearing steels, which typically contain coarse carbides in their microstructures. Nanostructured bainitic bearing steel has been proposed for bearing components, which are highly demanding.

The study has highlighted several other interesting research directions for high-strength nanostructured bainitic steels and serves as a significant addition to the knowledge base in this research area.

Schematic illustration of advanced high-strength bainitic steels (within the dashed blue line) vs. C content and size of the cross-section of the part. Image Credit: Morales-Rivas, L, Metals

Future Research Directions

The authors have stated that future research directions should include the use of simple and standard chemical compositions as alloying elements for these steels. This would improve recyclability, which is more in line with the concept of a circular economy. Fine-tuning of the microstructure will be significantly advantageous for material design.

Moreover, the authors have stated that efforts should be made to decrease the bulk carbon content, which may necessitate the integration of thermochemical stages during manufacturing. This is more viable for parts that have a smaller cross-section. The development of thermally stable microstructures using continuous air-cooling will be advantageous for both manufacturing and assembly purposes.

Further Reading

Morales-Rivas, L (2022) Viewpoints on Technological Aspects of Advanced High-Strength Bainitic Steels [online] Metals 12(2) 195 | mdpi.com. Available at: https://www.mdpi.com/2075-4701/12/2/195

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.