The photonic assembly service provider PHIX builds on Nanoscribe’s high-performance 3D printing solution with alignment capabilities to offer 3D-printed standard lensed fiber arrays.

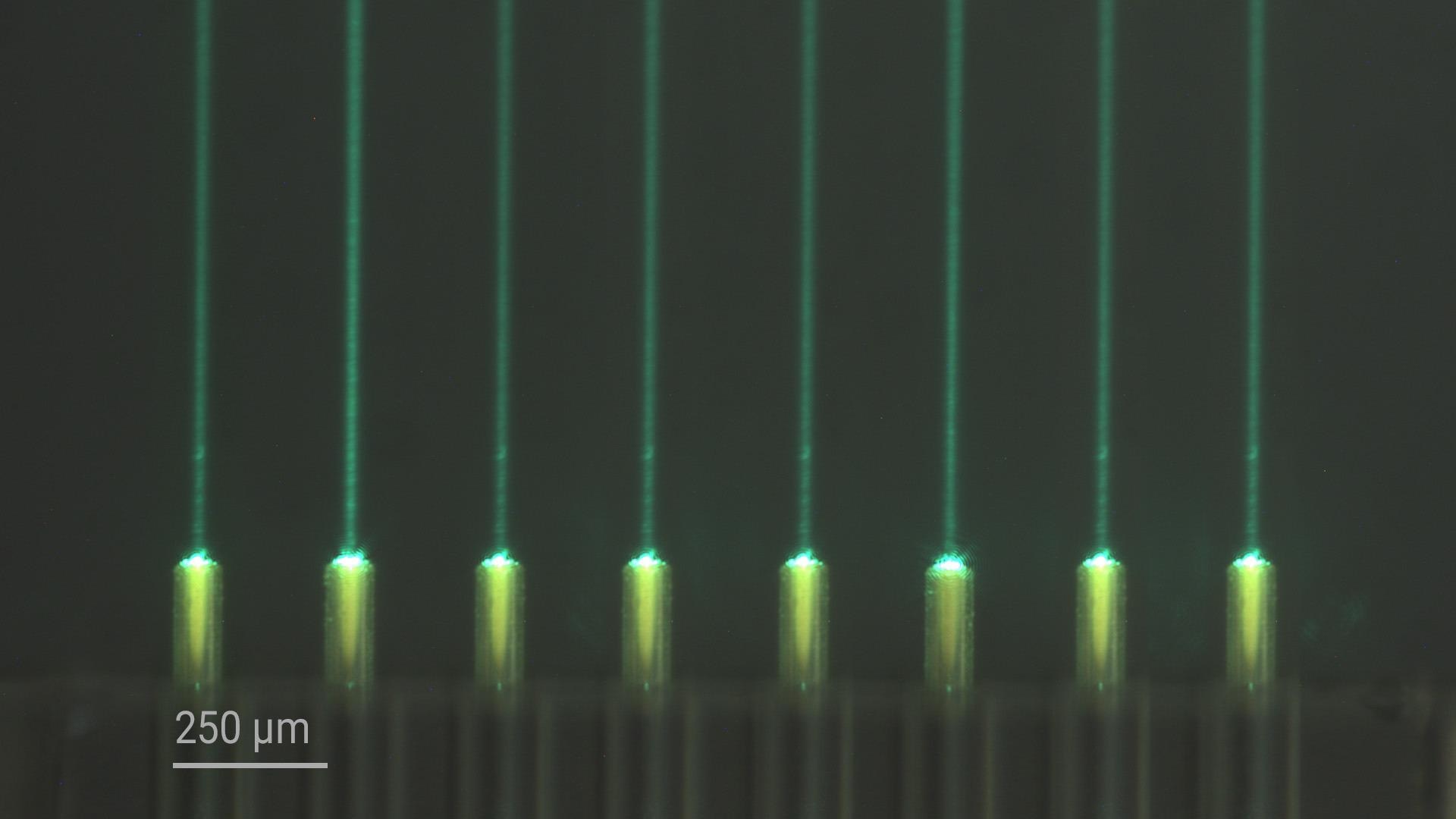

Microscope image of a 3D-printed lensed fiber array (LFA). The microscope image clearly demonstrates how precise the optical projection of lensed fibers is. Here, green light is collimated into parallel light beams. Sample of the research project MiLiQuant. Image Credit:

Nanoscribe, a BICO company, and the Dutch photonics packaging foundry PHIX B.V. have announced a collaboration to provide on-fiber printing services to the photonic packaging industry. With Nanoscribe’s new high-performance 3D microlens printing technology with nano-precision alignment capabilities, PHIX relies on this new technological approach in their manufacturing services of standard lensed fiber arrays (LFAs). The PHIX service portfolio will then contain the manufacturing of Free Space Microoptical Coupling (FSMOC) components printed directly on fiber arrays and photonic integrated circuits (PICs). This extends PHIX’s portfolio for bringing hybrid integration into mass production.

Both partners take a multidisciplinary approach to the development of photonic packaging solutions: from simulation to design and assembly. Nanoscribe’s Quantum X align automatically aligns and prints advanced optical lenses on fiber arrays, facilitating optimized optical coupling on PIC platforms. In addition, this is a reliable solution for passive alignment of chip modules. PHIX is thus adding a state-of-the-art manufacturing technology to provide solutions for hybrid integration of chip-to-chip and fiber-to-chip modules to its portfolio of assembly services for all major PIC platforms.

“We are confident in Nanoscribe’s new, aligned 3D printing technology for producing lensed fiber arrays and lensed chips with virtually limitless optical designs,” stated Joost van Kerkhof, Chief Operations Officer (COO) of PHIX. “This will enable us to further advance integrated photonics packaging,” Van Kerkhof added.

“PHIX’s extensive expertise in assembly and packaging of photonic integrated circuits is a compelling fit for Nanoscribe to jointly validate and further advance our technology in an industrial environment,” said Jörg Smolenski, Business Developer at Nanoscribe. “We are excited to take manufacturing quality to the next level with our new approach of aligned high-precision 3D printing for manufacturing standard LFAs.”

The PHIX service is designed as a gateway to standard LFA manufacturing, facilitating entry into such markets. It is also promising for low-volume applications and markets with industry-quality components. With Nanoscribe’s technology, PHIX offers 3D-printed collimation, focusing and steering lenses on 4-32 channel fiber arrays. This is complimentary to PHIX’s offering of spot-size converters (SSCs) and can cover wavelengths from 450 to 1,550 nanometers and beyond. This marks an important milestone for the photonic packaging industry.