New research published online in Sustainability has presented a novel framework for modeling battery production.

Study: Digitization Platform for Mechanistic Modeling of Battery Cell Production. Image Credit: P5h/Shutterstock.com

Batteries are a key technology for the rapid electrification of industry and society, helping the world to achieve net-zero carbon emissions and mitigate the damage to the climate brought about by human activity. Significant progress has been made in terms of materials and device performance, but there are still opportunities for improvement, especially in the production process.

Batteries: A Vital Technology for Mitigating Climate Change

The damage caused by climate change has become apparent in recent years, with extreme weather events, flooding, and biodiversity loss all linked to a warming world. Fossil fuel use by industry and the transportation sector and the consequent greenhouse gas emissions have been intrinsically linked to climate change, facilitating the urgent need to mitigate the worst effects.

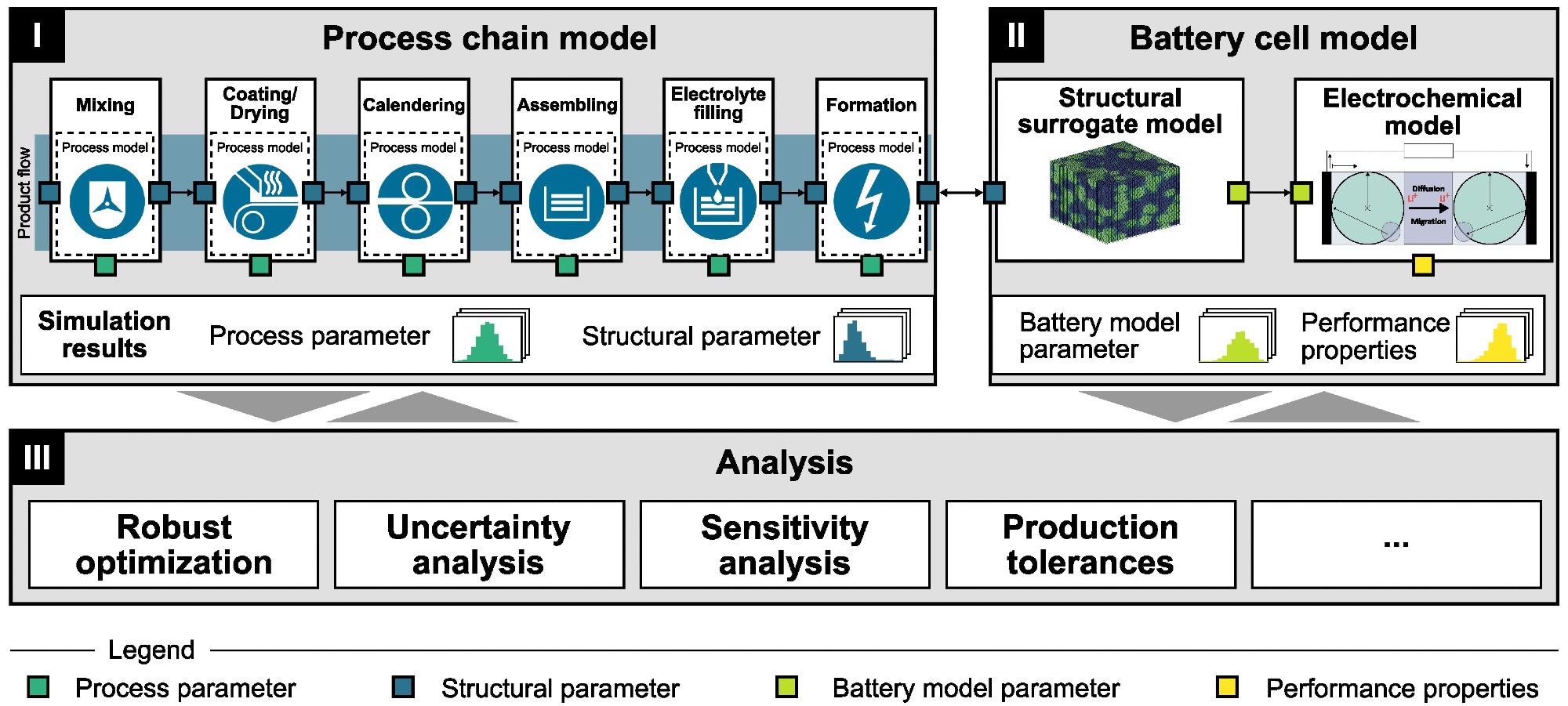

Schematic concept of the modeling framework consisting of three modules: (I) process chain model, (II) battery cell model, and (III) analysis. Image Credit: Thomitzek, M et al., Sustainability

Amongst the strategies proposed to mitigate climate change and reduce emissions, batteries have emerged as a key technology. The rise of electric vehicles and next-generation stationary energy storage devices has driven the rapid research, development, and implementation of battery technology in the transport and energy sectors. This dynamic transition is reflected in the increasing demand for battery cells and the ambitious targets of policymakers.

Increasing interest in battery cell technology has also led to a significant improvement in the performance of devices and materials and driven down the cost of battery cells from $668 in 2013 to $137 in 2020 - an 80% reduction. Future trends in battery technologies, including all-solid-state cells and lithium-sulfur batteries, promise enhanced performance and will foster new fields of application.

Current Challenges

Despite the considerable progress made over the last decade, challenges still exist with the wide-scale implementation of battery cell technologies in the transportation and energy sectors. In the case of electric vehicles, driving range and charging times are critical issues. Additionally, concerns over cost persist.

Additionally, besides design and materials, there is room for improvement in the production process. Manufacturing battery cells is a complex process that includes a multitude of parameters and numerous performance relationships between products, processes, and structures, some of which are poorly understood. The entire process, from the extraction of raw materials to the finished product, involves many heterogenous steps. Consequently, production struggles to meet the demand of the electronics industry.

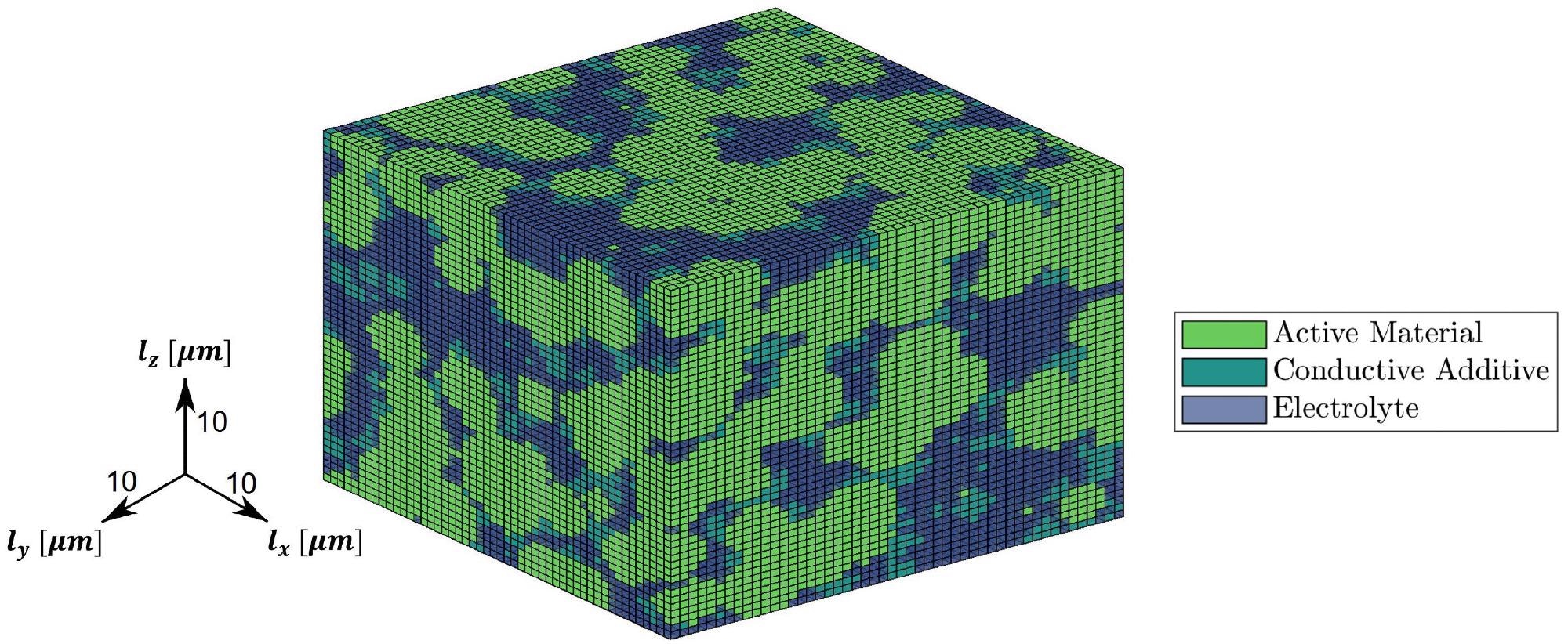

Waste from the battery industry has a growing environmental impact. Additionally, batteries themselves are complex devices, with the various structural parameters of individual components such as electrodes, electrolytes, and separators influencing the mechanical and electrochemical performance of the finished product. Even a slight change in these structural parameters can result in severe limitations of electrochemical performance such as capacity and energy density.

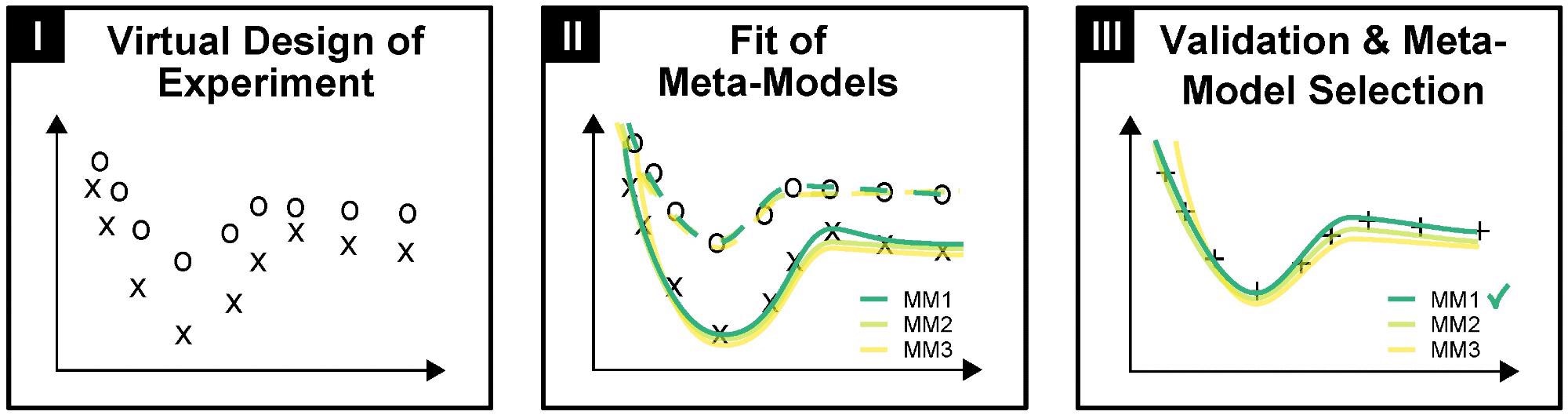

Meta-modeling approach consisting of (I) virtual design of experiment, (II) fit of meta-models, and (III) validation and meta-model selection. Image Credit: Thomitzek, M et al., Sustainability

The inherent challenges associated with the production process have driven research into modeling and optimizing the complex process steps and parameters to overcome the issues and improve the overall process.

Trial-and-error strategies are not suitable, especially on an industrial scale, because downtime, cost, quality, and waste are all impacted. A framework for the non-invasive improvement of the process chain and devices is needed to further enhance the technology and its applications in an emerging, sustainable transportation and energy sector.

The Study

The new study published in Sustainability seeks to improve the production process and technology by developing a framework that integrates mechanistic models of the entire production process and battery cell technologies to accurately represent real-world conditions. Thus, the framework can determine the production process’s effect on the performance of the technology.

The framework proposed in the study is based on transparent product structure performance and process-product structures rather than trial and error methods, which can be costly, inefficient, and lead to increased scrappage and waste. Knowledge-based and low-cost improvements are enabled by the proposed framework. Mechanistic models were preferred over data-driven models due to their ability to extrapolate beyond the initial design space.

The authors state that improvements in battery performance and production cost savings due to lower rates of scrappage overcomes barriers to the success of electric vehicles and will contribute to more sustainable transportation and energy sectors.

Exemplary voxel-based 3D microstructure. Image Credit: Thomitzek, M et al., Sustainability

Overall, according to the authors, targeted decision support for production and product design could be achieved by implementing the proposed framework and performing digital experiments. This confers significant benefits for the quality of the technology and the production process, as well as reducing the environmental impact of battery production.

Future opportunities have been identified by the authors, including the further implementation of process models focusing on cell assembly and anode production and extending the process chain model by considering energy and material flows along the entire production chain. Additionally, they have stated that digitization platforms for mechanistic models have the potential for real-time control of different production steps in a production system that combines both physical and virtual elements.

Further Reading

Thomitzek, M et al. (2022) Digitization Platform for Mechanistic Modeling of Battery Cell Production [online] Sustainability 14(3) 1530 | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/3/1530

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.