In an article recently published in the journal Frontiers in Materials, researchers reported the development of orthodontic aligners using four-dimensional (4D) technology.

Study: Potential Application of 4D Technology in Fabrication of Orthodontic Aligners. Image Credit: G Estudios Multimedia/Shutterstock.com

The researchers investigated and evaluated the forces produced by three-dimensional (3D)-printed shape memory polymer aligners, which are also known as four-dimensional (4D) aligners.

Background

Aesthetics is one of the most important considerations for patients seeking dental treatment. Orthodontic aligner treatment has gained popularity in the recent decade. Because the aligners are clear, practically undetectable, and easily removable during eating, brushing, and flossing, they have significant cosmetic, comfort, and oral hygiene benefits over the fixed braces.

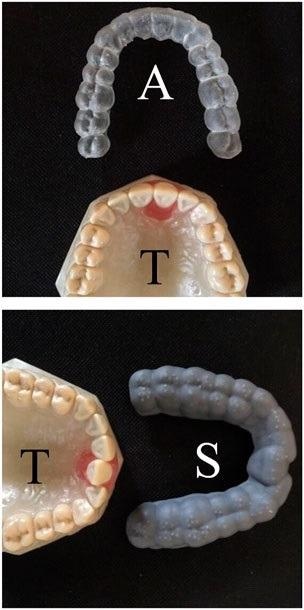

A custom-made typodont (T), a 4D-printed aligner (A), and a gray splint (S). Image Credit: Elshazly, T. M. et al., Frontiers in Materials

Orthodontic aligners became more efficient with the development of digital scanning, 3D printing, and computer-aided design/computer-aided manufacturing (CAD-CAM) technology. However, researchers are constantly attempting to improve the treatment's efficacy. To biologically accelerate the tooth movement, a variety of approaches have been introduced. Shape memory polymers (SMPs) are one of the newest materials to enter the world of dentistry, especially for orthodontic purposes. They hold a lot of potential for use in medicine.

However, there is a scarcity of research about the use of SMPs in orthodontic aligners. The 3D printing of shape memory materials is the basis for the 4D printing technology. 4D-printed components possess the ability to alter the shape over time (the fourth dimension) depending on the surroundings. New 4D printing applications in the product design industry are predicted to grow as SMPs continue to improve.

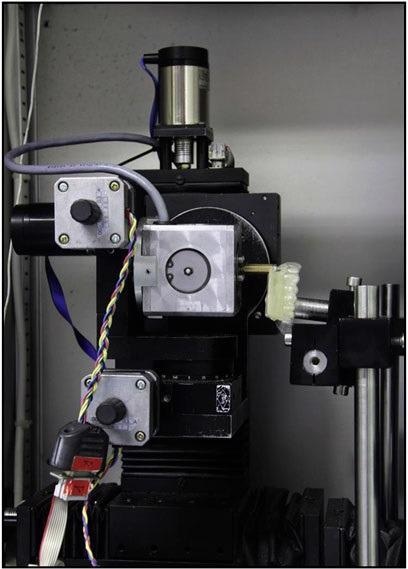

Three-point bending test of a 4D-printed specimen using the orthodontic measurement and simulation system (OMSS) at different temperatures. Image Credit: Elshazly, T. M. et al., Frontiers in Materials

About the Study

In the present study, the rectification of the malposition of tooth 21 (a maxillary central incisor) by 4D-printed aligners having thickness values of 0.8 and 1.0 mm was evaluated by the superimposition of consecutive scans (acquired and initial) on a custom-made typodont model. The researchers used ClearX v.1.1 (a 3D-printable material) with thermoresponsive shape memory capabilities to produce orthodontic clear aligners, also called 4D aligners.

A typodont model was employed as an early confirmation of the tooth movement. The study used a simple orthodontic case in which only one tooth (tooth 21) was moved bodily, while the remaining teeth were kept fixed in the resin and were used to hold the entire aligner in place. In three-point bending (3-PB) experiments, the maximum forces generated on a 2-mm deflection by foil sheet specimens were estimated at various temperatures.

A custom-made biomechanical device (orthodontic measurement and simulation system [OMSS]) was also used to assess the forces generated by the 4D aligners on the movements/shape recovery of tooth 21 at different temperatures.

Orthodontic measurement and simulation system (OMSS): a resin replica with a 4D-printed aligner is mounted in the system. Tooth 21 to be analyzed was connected to a computer-controlled 3D sensor. The measured moments and forces are registered, and the motor-driven positioning table simulates the analyzed tooth movement. Image Credit: Elshazly, T. M. et al., Frontiers in Materials

Observations

In this study, 4D aligners were able to achieve a large tooth displacement (2.5 ± 0.5 mm) with no significant difference between various thicknesses on the typodont. Maximum deflection forces measured at 20, 30, 37, 45, and 55 °C were 3.8 ± 1.1, 2.5 ± 0.9, 1.7 ± 0.6, 1.0 ± 0.4, and 0.5 ± 0.4 N, respectively, in the 3-PB test. 0.8-mm aligners delivered forces of 0.3 ± 0.1, 0.2 ± 0.1, and 0.7 ± 0.2 N on palatal displacement of tooth 21 at 37, 45, and 55 °C, respectively, whereas 1.0-mm aligners exerted forces of 0.3 ± 0.1, 0.3 ± 0.1, and 0.6 ± 0.2 N, respectively.

The shape memory aligner was successful in achieving a considerable movement of tooth 21 on the typodont, as well as a congruent movement in the OMSS. The movement accomplished with one shape memory aligner was roughly equal to that achieved with 10 conventional aligners.

The highest force generated on a deflection of 2 mm at temperatures in the range of 37 to 55 °C (the material's activation temperature range) with a sheet thickness of 1 mm spanned in the range of 1.20 to 0.50 N. It was also observed that as the temperature rises, the maximum forces decrease, which can be attributed to the fact that heat causes softening of such thermoplastic materials by initiating debonding of the secondary bonds corresponding to the cross-links, thereby weakening the material.

The generated forces measured by OMSS (0.30–0.70 N) at various temperatures i.e., 37, 45, 55 °C were also within the range of permissible physiological orthodontic forces. The forces produced at 50 °C were stronger than those produced at 37 °C. As compared to the forces at 37 and 55 °C, there was a drop in forces at 45 °C. Except in the OMSS at 55 °C, the thicker aligners had no major impact on the generated force.

Conclusions

In conclusion, this study demonstrated the capacity of a 3D-printed aligner composed of SMPs (4D aligner) to move teeth using biocompatible orthodontic forces following an appropriate thermal stimulation within the oral temperature range. They also reported that the recovery and deformation temperatures have the largest impact on the shape memory properties of 4D-printed materials.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Elshazly, T. M., Keilig, L., Alkabani, Y., et al. Potential Application of 4D Technology in Fabrication of Orthodontic Aligners. Frontiers in Materials 8 (2022). https://www.frontiersin.org/articles/10.3389/fmats.2021.794536/full