Solar harnessing devices require optimized, high-performance materials to ensure they are as efficient as possible. A recent paper presented in the journal Coatings looks at the use of thin films comprised of TiO2 and reduced graphene oxide (TiO2–rGO) as an increasingly popular material in solar harvesting devices.

Study: Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices. Image Credit: Daniel Ramirez-Gonzalez/Shutterstock.com

A key driver in the wider adoption of TiO2–rGO is the development of charge-transporting characteristics. The paper’s authors develop and test a facile spin-coating methodology suitable for depositing crack-free TiO2–rGO thin films with controllable levels of thickness, ideal for a range of solar harnessing devices.

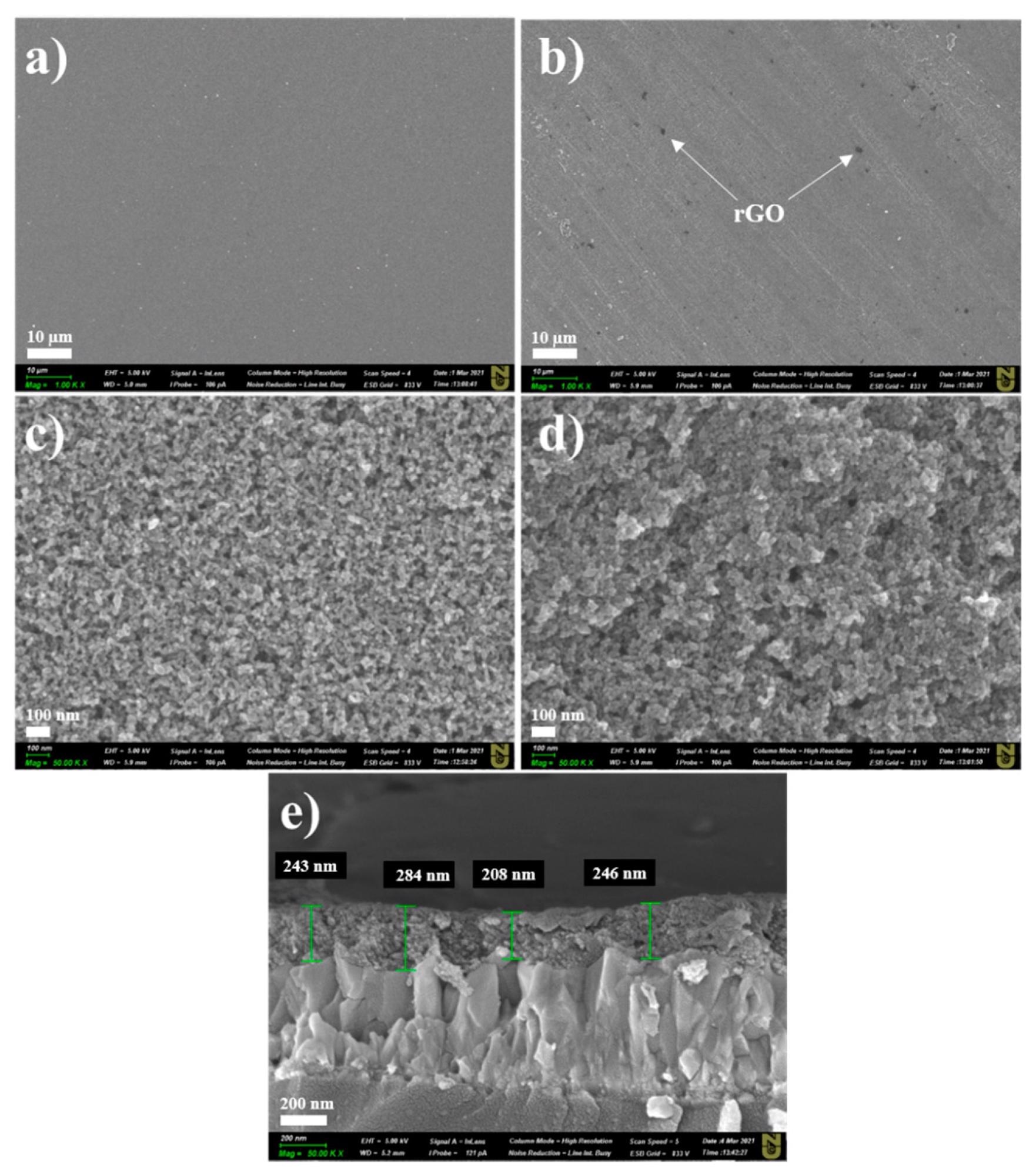

Low-resolution SEM images of (a) TiO2 film and (b) TiO2–rGO film (scale bar—10 µm). High-resolution SEM images of (c) TiO2 film and (d) TiO2–rGO film (scale bar—100 nm). Cross-sectional SEM image of (e) TiO2–rGO film (scale bar—200 nm). Image Credit: Khamkhash, L et al., Coatings

Mesoporous TiO2 thin films already see extensive use in solar harvesting devices’ electron transport layers. Popular techniques include dye-sensitized solar cells, photoelectrochemical cells, and perovskite solar cells – but many of these TiO2 thin films suffer from limited electron transport efficiency due to factors such as recombination, charge trapping, and grain boundary scattering effects.

The authors cite these issues as key motivators of the need to develop a means of fabricating TiO2 thin films which offer both improved charge transfer and a reduced tendency for charge recombination.

They focus on the addition of rGO into TiO2 films as an efficient means of addressing these issues.

While a number of methods can be used to prepare TiO2–rGO films – for example, aerosol-assisted chemical vapor deposition combined with dip-coating and spray pyrolysis – these methods tend to produce TiO2–rGO films with uneven thicknesses, rough surfaces, and cracks.

The key challenge to date has therefore been the deposition of crack-free TiO2–rGO films with controllable thickness – essential qualities for solar harvesting devices. In order to be applicable in industrial settings, it is also vital that any developed methodology be rapidly implementable, straightforward, and as scalable as possible.

Spin-coating has historically been the most commonly employed approach to preparing polymeric films, photoelectrochemical cells, perovskite solar cells, and metal oxide-based sensors.

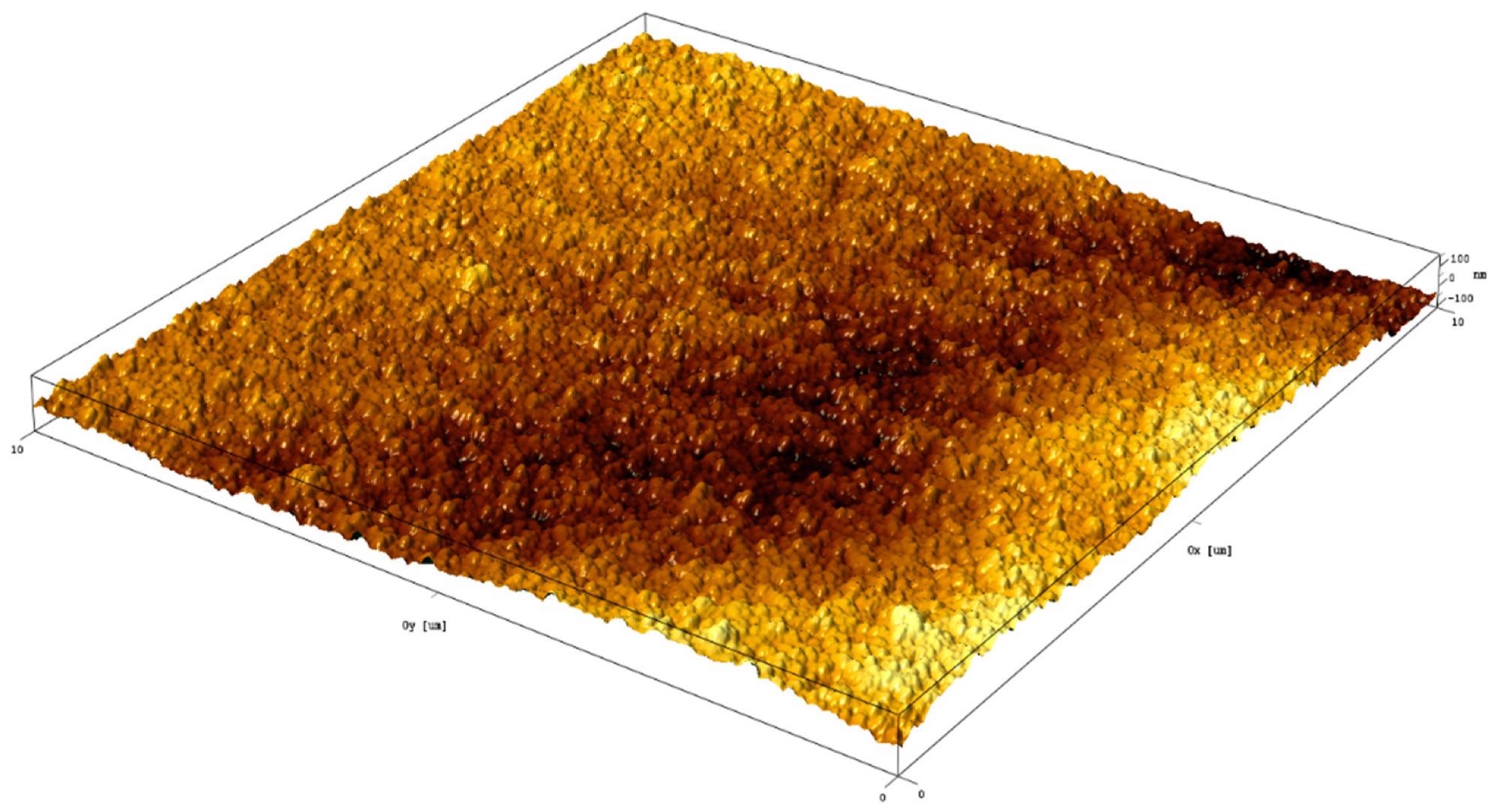

AFM 3D image of images of TiO2–rGO film. Image Credit: Khamkhash, L et al., Coatings

This method has proven to offer good control over film thickness and relatively straightforward deposition.

The success of this existing method led the paper’s authors to focus on the development of a facile spin-coating methodology that would allow them to deposit crack-free TiO2–rGO thin films that are reliable and robust enough to meet the stringent performance requirements of solar harvesting devices.

Not only would this method meet relevant application needs around scalability and ease of implementation, but the authors also believed that it would result in the enhanced charge-transporting properties necessary to ensure performance efficiencies.

Having selected and employed an appropriate deposition method that was able to meet these performance requirements, the paper’s authors employed a number of characterization techniques to confirm that the TiO2–rGO thin film had formed correctly and that it was sufficiently even and crack-free.

EDX elemental mapping confirmed that the rGO had been correctly incorporated into the TiO2 thin film, with rGO nanoflakes appearing as carbon-rich spots in the resulting images.

AFM was used to evaluate surface roughness, confirming that this did not have an impact on the film’s effectiveness.

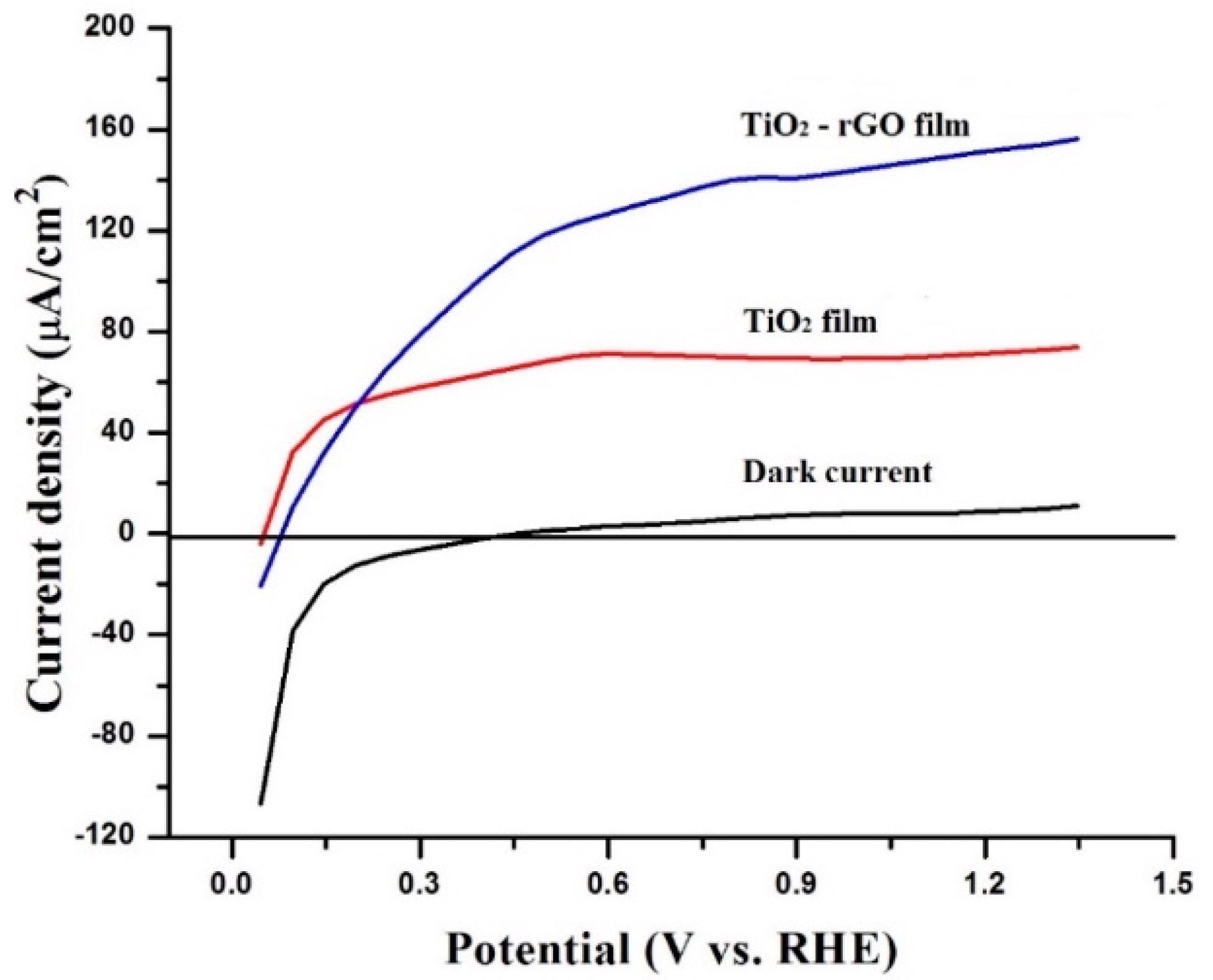

In order to confirm that the charge-transporting properties of the TiO2–rGO composite thin films demonstrated a tangible improvement over their TiO2-only counterparts, their photoelectrochemical (PEC) activity was evaluated under simulated solar light illumination.

It was determined that the TiO2–rGO composite thin film yielded an improved photocurrent response (~151.3 µA/cm2) versus the bare TiO2 thin film (~71.6 µA/cm2) at 1.23 eV - results that would suggest the addition of rGO significantly improved the TiO2 films’ charge-transporting properties.

The paper’s authors did note, however, that high levels of rGO in TiO2 films could result in light-blocking effects, which would actually be detrimental in terms of the films’ charge-transporting properties.

Photocurrent densities of TiO2 and TiO2–rGO films without and with light illumination. Image Credit: Khamkhash, L et al., Coatings

There is, therefore, further work to be done to evaluate the implementation of rGO at different concentrations, facilitating the optimization of TiO2–rGO films and the determination of the right balance of charge-transporting properties without limiting the amount of light entering the solar harvesting device.

This work opens up new avenues for optimizing the performance of solar harvesting devices, with rGO potentially acting as a valuable addition to a range of other film types. The authors propose that their refined method could be further expanded to incorporate the preparation of a range of metal oxide–rGO films, including ZnO–rGO and SnO2–rGO.

References

Khamkhash, Laura, Svetlana Em, Anara Molkenova, Yoon-Hwae Hwang, and Timur S. Atabaev. 2022. "Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices" Coatings 12, no. 2: 218. https://www.mdpi.com/2079-6412/12/2/218

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.