A team of researchers at the Institute of Sciences and Technologies for Sustainable Energy and Mobility (STEMS), Turin, Italy, have published a report in the journal Sustainability on potential eco-friendly materials that could be used in the production of brake pads.

Study: Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents. Image Credit: LightField Studios/Shutterstock.com

Traffic-related sources have been established as a major contributor of particulate matter (PM), specifically within major cities, raising an eco-awareness about the need to develop green products and materials for use in vehicle components. A strategy that is deemed vital to reducing pollution in tandem with ushering in new, stringent regulations aimed at preventing the environment from further damage.

The new study follows on from relatively recent environmental regulations that stipulate brake systems should produce low-polluting compounds as PM in the nonexhaust category is primarily emitted by friction materials.

“In 1987, the WHO developed quality guidelines, followed by updates in 1997 and in 2006, recommending maximum levels of several critical air pollutants that can have negative effects on human health,” explains the paper’s co-author Giovanna Gautier di Confiengo of STEM.

Particulate Matter

Particulate matter (PM), also known as particle pollution, is a term for a mixture of solid particles and liquid droplets found in the air. There are a number of particles that are large or dark enough to be seen with the naked eye while others are microscopic and require special equipment to detect.

In a separate study, it was observed that around 35% of brake pad mass lost from braking ends up airborne with around 18% of particulate matter being carbonaceous making it a risk to both human health and the environment.

As the global consciousness shifts towards developing green solutions such as the wider adoption and acceptance of electric vehicles (EVs), the number of vehicles on the road continues to increase in line with population growth. Like all other vehicles, electric vehicles also emit particulate matter (PM) from tire and brake wear, which can contribute to respiratory disease.

Furthermore, due to the increased weight of EVs, they are thought to emit more friction particles from braking at higher levels than conventional vehicles. While the benefit of adopting EV technology to help reduce exhaust emission is unquestionable, researchers believe that improving and developing green materials for use in all vehicles could further improve PM levels in the air.

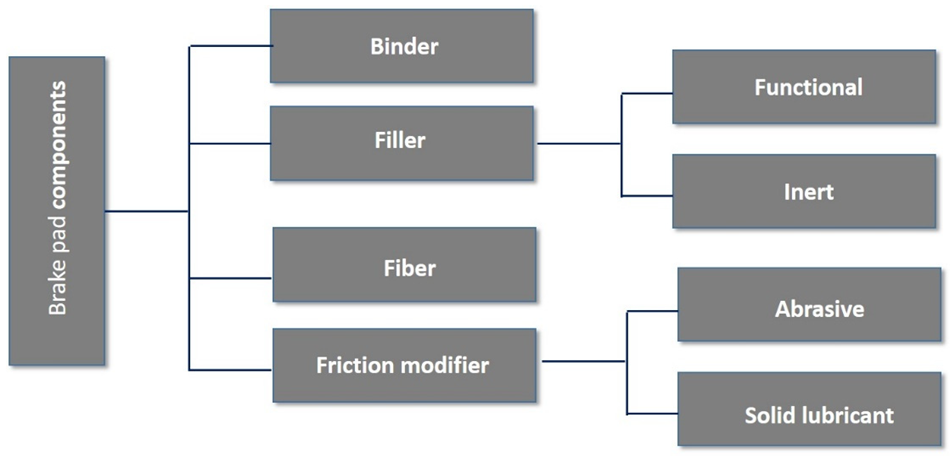

Friction material constituent classification. Image Credit: Gautier di Confiengo, G.; Faga, M.G, Sustainability

Potential Materials for Green Brakes

The researchers detail potential materials by categorizing the friction material constituents that make up modern braking systems into binders, fibers, friction modifiers, and fillers. While conventionally synthetic phenolic resins are used as binders, they can lead to the emission of volatile organic compounds (VOCs) such as formaldehyde during production and wear.

During the research, Gautier and her colleague Maria Giulia Faga investigated lignin, a phenolic polymer that forms part of the plant cell wall, as a potential binder alternative due to it being a more stable friction coefficient than conventional materials.

Furthermore, geopolymers and bioresins were also considered as alternative binder materials: “A comparable mechanical strength with traditional friction materials has been achieved using bioresin, while promising results in terms of general performance were obtained with geopolymers,” explains Faga.

Throughout the study, Gautier and Faga evaluated a variety of natural fibers from the research EU Patent Office site, including flax, palm kernel, agave, and aloe which all demonstrated to be the most promising to replace materials such as man-made aramid fibers. However, the natural fibers exhibit less uniform and rigid properties than the synthetic materials, so further work is needed to improve such factors.

While some of the primary friction modifiers used for the fabrication of friction materials cannot be considered completely green materials, Gautier explains, “they are nontoxic for humans and the environment.” Adding, “Some interesting papers dealing with two boron compounds, such as ulexite and colemanite, report promising results.”

With respect to the filler materials, there is a range of natural materials that show potential application use in braking systems. “Rice husk, ground nutshell, periwinkle shell along with maize husk can be valid alternatives to conventional fillers,” says Gautier. Furthermore, the researchers also discovered that these natural materials do not require chemical treatments which boosts their green credibility.

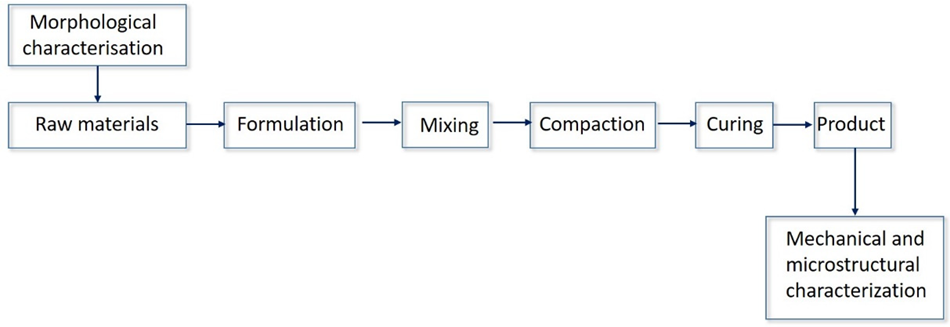

Brake pad manufacturing process. Image Credit: Gautier di Confiengo, G.; Faga, M.G, Sustainability

Eco-Friendly Brakes

Both Gautier and Faga have revealed that there are potential alternative materials for the green production of brake pads, which would reduce the emission of hazardous particulate matter (PM) into the environment and could make production a more sustainable practice.

Eco-friendly brake pads would not only have an environmental benefit and mitigate the risk of worsening or causing respiratory illnesses, but the researchers do state that further work and investigation are required to find completely green friction materials.

Besides investigating the use of natural products to replace synthetic products, Gautier and Faga state that there has been also an increase in the potential use of waste as an alternative: “Indeed, tire rubber, aramid recycled fibers and cement from the cement industry have been the subject of some research papers,” they say.

Further research into eco-friendly brake pads could show how a switch to natural fibers could offer a more sustainable future and mitigate the environmental impact of particulate matter emitted from friction materials.

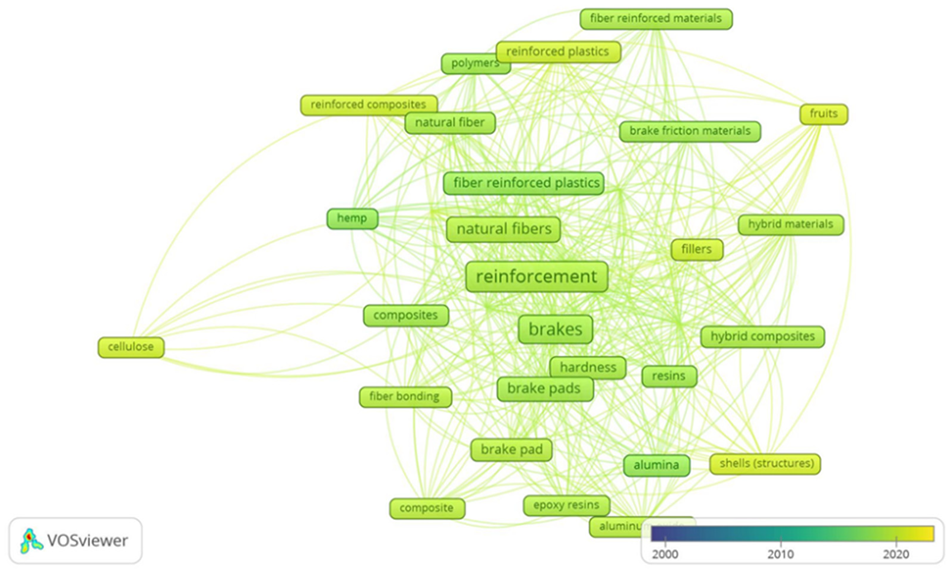

Representation of the relations between different keywords emerging from the analysis of the terms ”brake pad (friction materials)” and “natural fiber”. Image Credit: Gautier di Confiengo, G.; Faga, M.G, Sustainability

References and Further Reading

Gautier di Confiengo, G.; Faga, M.G. Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents. Sustainability 2022, 14, 2508. https://www.mdpi.com/2071-1050/14/5/2508

Bhagwan D. Garg, Steven H. Cadle, Patricia A. Mulawa, Peter J. Groblicki, Chris Laroo, and Graham A. Parr. ‘Brake Wear Particulate Matter Emissions’. Environmental Science & Technology 2000 34 (21), 4463-4469. https://pubs.acs.org/doi/abs/10.1021/es001108h

Cross. D.J., “Monitoring and Mitigation of Tire Microparticles’. AzoMaterials https://www.azom.com/news.aspx?newsID=5761

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.