By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 28 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 28 2022In an article recently published in the open-access journal Materials, the researchers reported the utility of spent coffee grounds as a non-load-bearing structure's construction material.

Study: Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Image Credit: Nor Gal/Shutterstock.com

Background

Over the last 10 years, global energy consumption has increased dramatically. This rise is due to population growth, fast urbanization, and economic development, which has resulted in a worldwide increase in demand for heating and cooling, as well as an increase in CO2 emissions.

As a result, since the first oil crisis, successive government thermal regulation policies have pushed for environmental responsibility by adopting eco-friendly composite materials in various building applications while following a sustainable development approach. Researchers are exploring innovative alternatives as well as low environmental impact materials, while having a special focus on bio-sourced materials as a result of the steady development of government regulations towards a modern construction sector.

The life cycle of coffee. Image Credit: Moussa, T et al., Materials

Coffee is the world's second-largest market, behind oil, and a widely traded beverage around the world. Coffee consumption produces solid waste in the form of spent coffee grounds (SCG). SCGs can be recovered and reused in a variety of ways due to their unique physical and chemical qualities.

About the Study

In the present study, the authors presented the investigation of the mechanical, thermal insulation, and sound absorption properties of a potato starch/spent coffee grounds bio-based composite for its prospective use in buildings. The coffee grounds waste bio-composite was characterized as an insulating substance equivalent to typical plant-based thermal insulation materials based on thermal conductivity and diffusivity studies.

Acoustical testing was done to evaluate the absorption coefficients, which were then compared to those seen in other common acoustical materials.

The compressive mechanical behavior of this bio-sourced material was tested. Also, its suitability for non-load-bearing buildings and mechanical capacity towards the development of construction bricks were evaluated. The impact of the humid environment on the mechanical, thermal, and acoustic performance was determined.

The foundation was laid for a preliminary examination of how this composite will perform in two climates: the continental environment of Reims, the tropical climate of Belém, France, and Brazil. The SCGs were characterized, and their feasibility in construction applications when mixed with a mineral or vegetal binder was demonstrated. This research focused on the manufacture of a novel spent coffee composite material bonded with starch (SSCC), as well as its physical and mechanical properties for use in the construction industry.

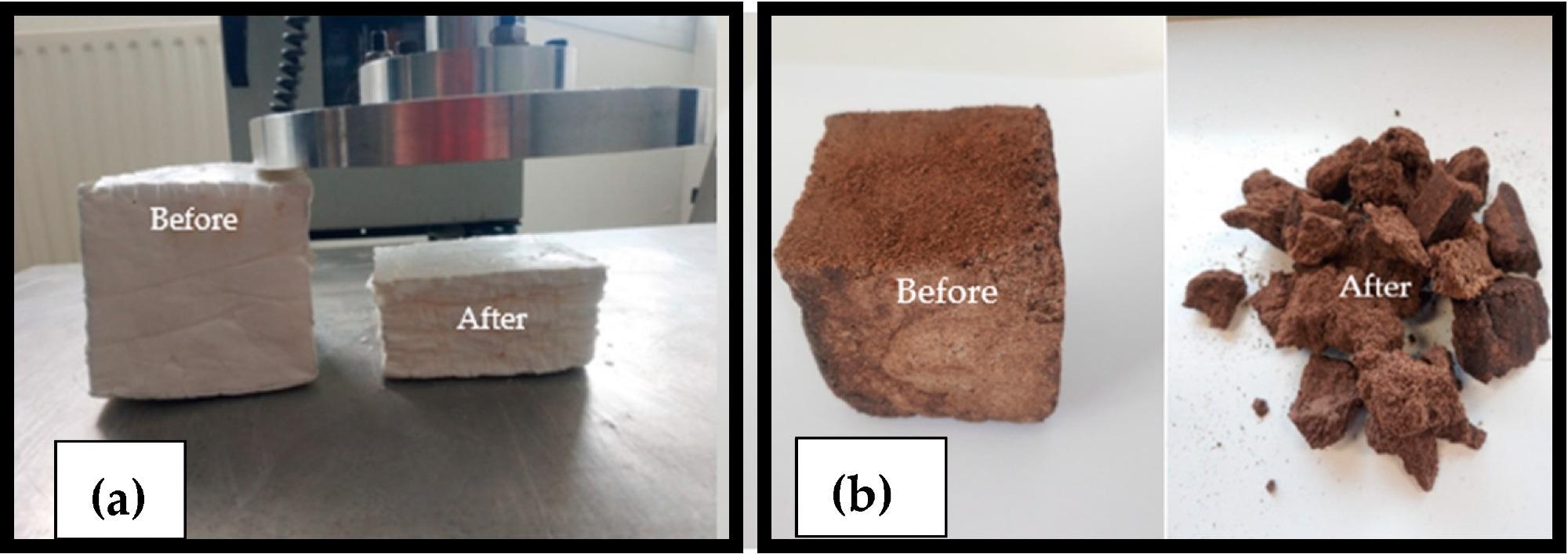

Cube-shaped SSCC-100 (a) and SSCC-40 (b) features before and after the compressive test. Image Credit: Moussa, T et al., Materials

Observations

The researchers observed that adding 60% of the weight of coffee grounds to starch increased thermal conductivity by 33%, resulting in a value of 0.093 W/(mK) for SSCC-40. The diffusivities of SSCC100 and SSCC40 were found to be around 0.40 x 10-6 m2/s. In addition, the SSCC-40 could achieve absorption peaks of 0.6 at 1000 Hz for 2 cm and a double peak of 0.85 at 700 Hz and 1.0 at 2300 Hz for 4 cm acoustically.

Furthermore, it was observed that the αw coefficient was more than 0.5, which proved that the coffee grounds bio-based material had good acoustic qualities for the construction industry. The SCG composite SSCC-40 was shown to have a better-weighted absorption coefficient (αw = 0.37) than rock wool (αw = 0.25). It was also shown that unlike the SSCC-100, which has a quasi-linear behavior, the moisture sorption isotherm for SCG (SSCC-0) and SSCC-40 had strong non-linear and sigmoidal-shaped characteristics with exponential rise over 65% RH.

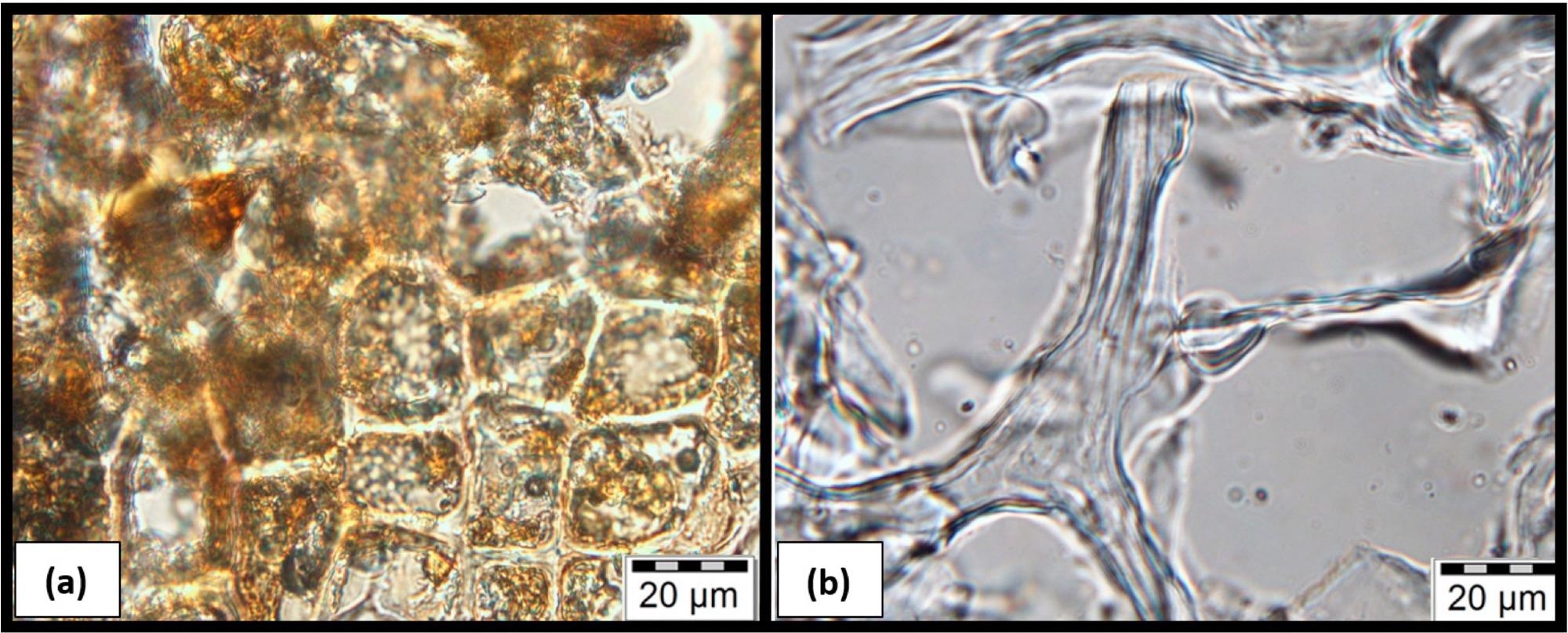

It was also determined that the compression process of SSCC-100 had three stages: a linear elastic stage at low stresses regulated by cell wall bending, a second phase corresponding to cell collapse, interrupted by a densification period in which the stress rose steeply. Young's modulus increased as the starch concentration decreased. The value for the starch sample was 3.38 MPa, while the SSCC-40 sample had a value of 6.09 MPa.

Microscopic photographs of microtome slices of (a) SSCC-40 showing dark coffee particles embedded in clear starch gel. (b) SSCC-100 displays clear starch gel filaments and large voids (vacuoles). Image Credit: Moussa, T et al., Materials

Conclusions

In conclusion, this study elucidated the realistic strategy to managing leftover coffee grounds that may be recycled and used as insulation in the construction sector. The authors observed that this new bio-composite, which includes a plant-based binder made from potato starch, is intended to be a long-term replacement for mineral or petroleum-based chemicals, which deplete resources.

The authors emphasized that the results presented here could lead to the development of this type of environmentally beneficial building material.

More research into the hydric behavior of this completely bio-sourced material in distinct hot and cold humidity conditions, such as those found in the humid continental climate of northern France and the Amazonian tropical climate of Brazil, is required.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Moussa, T., Maalouf, C., Bliard, C., et al. Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures. Materials 15(5), 1689 (2022). https://www.mdpi.com/1996-1944/15/5/1689