A team of researchers from New York in the USA has explored the development of aesthetically pleasing aerogels for window design, which has implications for reducing heat loss in structures, with the possibility of use in green building design. Their research has been published online this week in the journal Sustainability.

Study: Aesthetic Aerogel Window Design for Sustainable Buildings. Image Credit: ninimf/Shutterstock.com

Building Heat Loss

Buildings lose around 25% of their heat through windows and other glazing units. Thermal loss, especially through non-double-glazed windows, can increase the energy costs for the average household. Double-glazing reduces some of the thermal loss through glazing units, but there is always room for improvement in technologies.

Recognizing the impact of thermal loss from buildings on climate change due to the increased energy demands for buildings, there have been several regulations enacted by governments that govern the construction of new buildings and retrofitting of existing structures. For example, in the US, there are the ENERGY STAR ratings, and EU member states must adhere to the Energy Performance Building Directive.

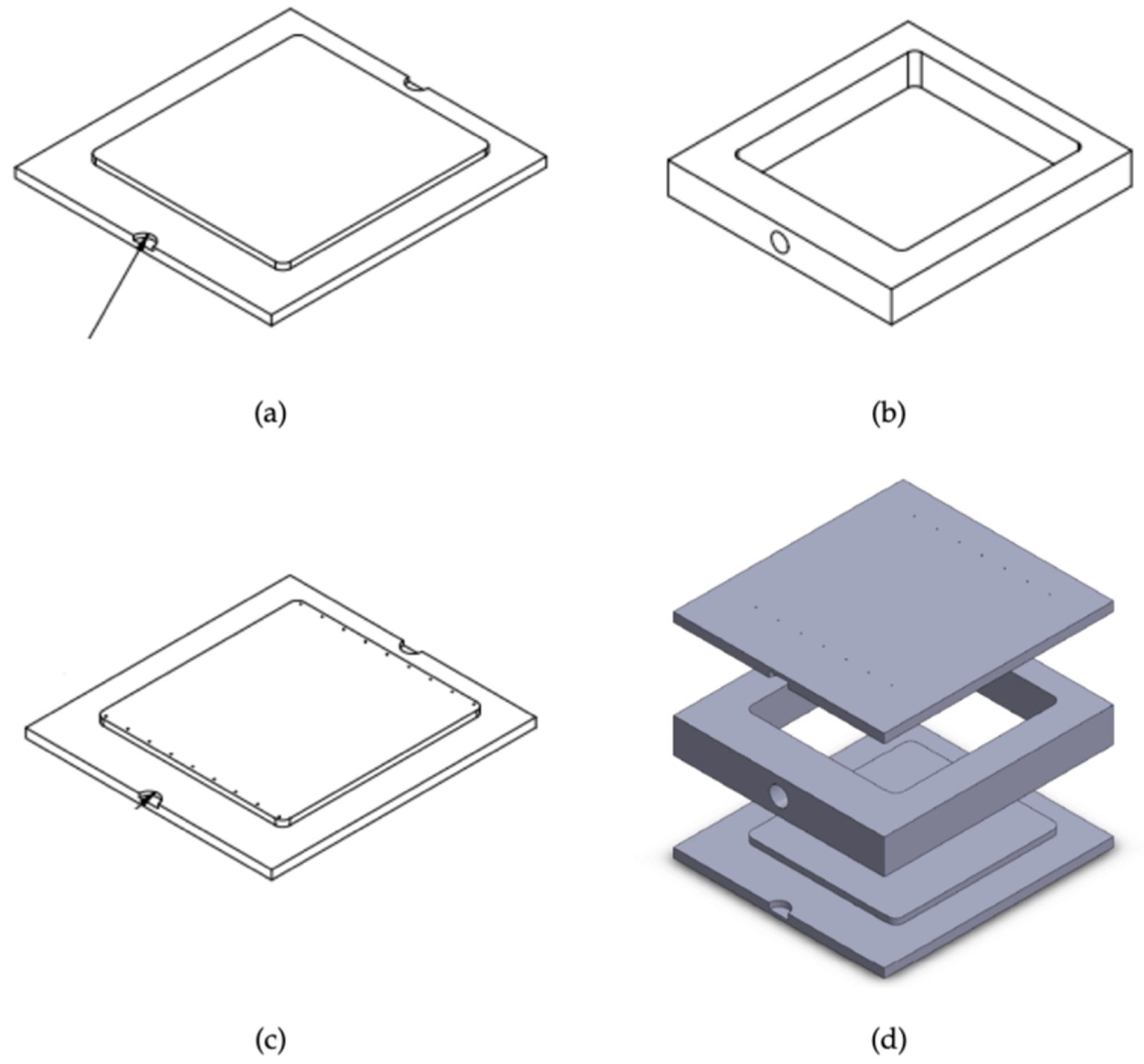

Schematic diagram of three-piece mold: (a) top piece; (b) middle piece; (c) bottom piece; and (d) assembly drawing. Image Credit: Carroll, M.K et al., Sustainability

Reducing Thermal Loss Through Glazing Units

In recent years, there have been multiple technological solutions proposed and developed to reduce thermal loss through windows and glazing units. These include double- and triple-paned windows, windows that have noble gases between their panes, vacuum glazing, photochromatic glass, low-emissivity windowpane coatings, and smart windows which possess user-controlled variable tints.

Aerogels are another proposed technological solution due to their attractive properties such as low thermal, electrical, and acoustic conductivity, and their optical translucence and even transparency. Aerogels are low-density mesoporous structures that are composed of 99.8% air by volume. Incredibly strong and light, they have been the focus of research in several technological fields and industries.

Silica Aerogels

Silica aerogels are synthesized from a silica precursor material. The synthesis process is typically a sol-gel reaction using alkoxides such as tetraethyl orthosilicate or tetramethyl orthosilicate. Mixing the silica precursor with a solvent mixture and adding an acid or base catalyst causes the mixture to undergo hydrolysis to form sol. Subsequent condensation reactions form a wet silica gel. Careful drying of this gel produces an aerogel with little or no shrinkage occurring.

The drying process can be carried out using freeze-drying, ambient drying, and supercritical extraction. Depending on the drying process, a granular, monolithic, or powdered aerogel can be synthesized.

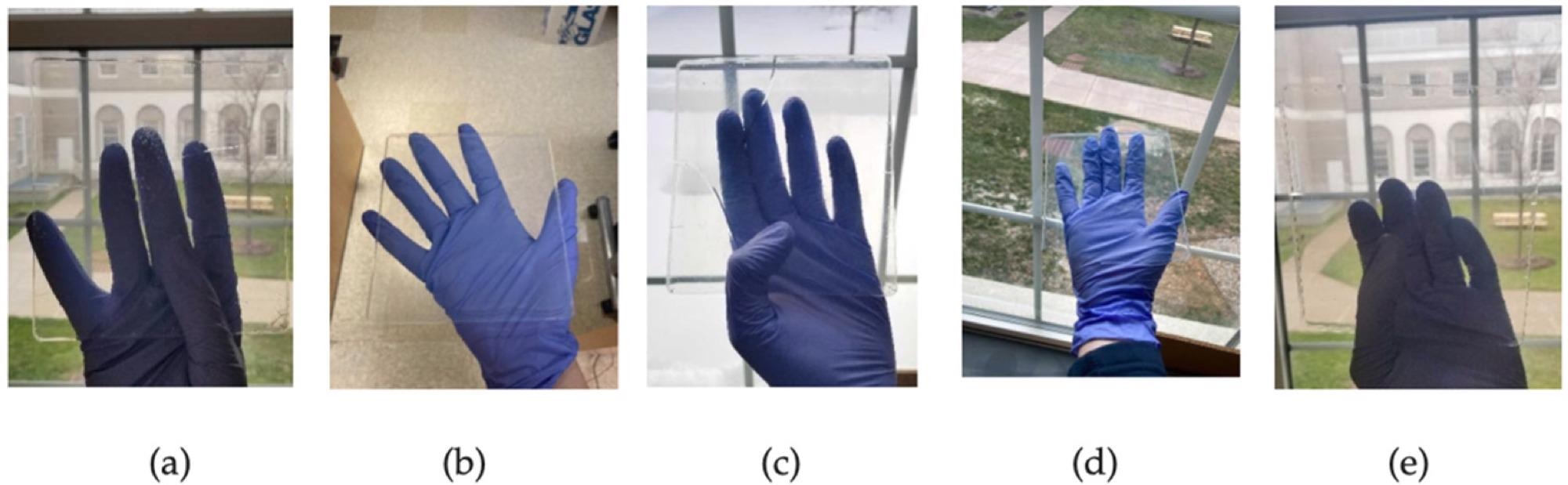

Images of 13 × 12.5 × 0.5 cm silica aerogel monoliths fabricated from: (a) Recipe A-1; (b) Recipe A-2; (c) Recipe B-1; (d) Recipe B-2; (e) Recipe B-3. Image Credit: Carroll, M.K et al., Sustainability

Granular Aerogel Glazing Products

Currently, there are some commercially available glazing products that exploit the properties of granular aerogel materials. These include Lumira®, which is manufactured by Cabot of Boston, Massachusetts in the USA. These commercial glazing solutions incorporate granular aerogels in their inter-pane spaces.

Whilst these products possess superior insulating capabilities, they suffer from a lack of transparency, which limits their use in applications where diffuse light is required, such as skylights. The challenges with manufacturing transparent glazing products which incorporate aerogels have facilitated growth in research in the area.

Research has been ongoing for decades, with a 1983 study discussing the use of transparent aerogels for window insulation, and a paper in 1998 categorizing monolithic aerogel’s superior thermal insulation properties but noting that light scattering in these materials is a significant disadvantage for their application in glazing units.

Several studies have investigated novel fabrication strategies for monolithic aerogel-incorporated windowpanes, with approaches such as changing the chemical precursor recipe to improve optical clarity and using monolithic aerogels pillars so only a small area of the pane is obscured. Whilst progress has been made, there are still significant challenges to overcome. Several start-ups in the area are manufacturing products.

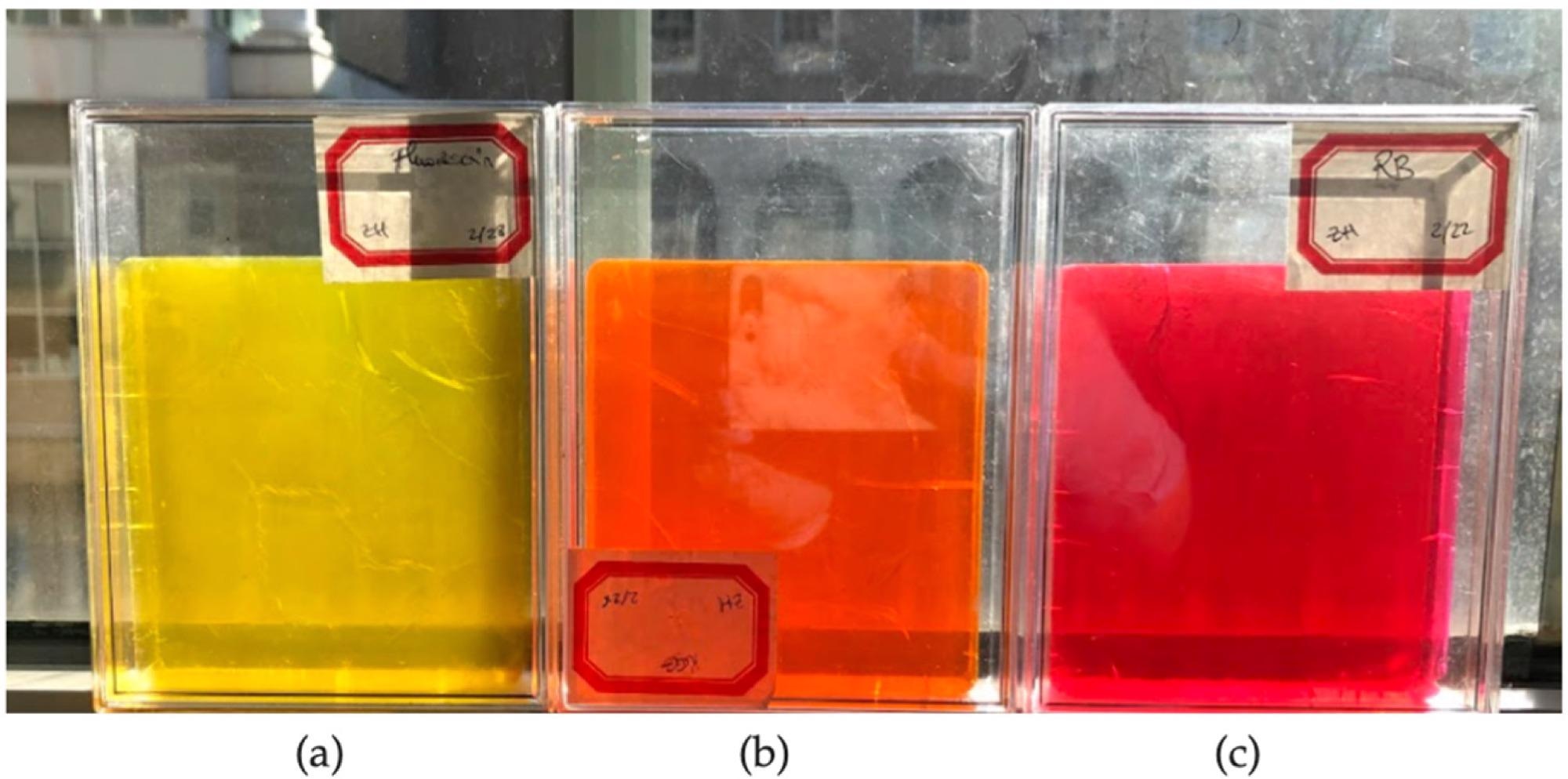

Images of 10 × 10 × 1.5 cm silica aerogels made with (a) Fluorescein; (b) Rhodamine 6G; and (c) Rhodamine B. Image Credit: Carroll, M.K et al., Sustainability

The Paper

The research published online in Sustainability has investigated several approaches for improving the aesthetics of glazing systems that use monolithic aerogels. Approaches including modifying the silica precursor recipe to improve optical clarity and using molds to vary the thickness of monolithic aerogel layers have been discussed in the study. Thinner layers are preferred in glazing system design as they possess shorter optical path lengths, resulting in less optical scatter.

The paper also describes an approach that masks some of the imperfections in monolithic aerogels using dyes, which makes them more visually appealing. This process uses laser etching of the aerogel surfaces and produces colored materials. The authors have explored rapid supercritical extraction, which can introduce color into monolithic aerogels without the risk of it leaching or being washed out to create aesthetically pleasing products.

The authors have described three prototype glazing units that incorporate monolithic silica gel and include one or more improvement methods tailored to individual applications. The prototype glazing units are constructed to give the appearance of a visually appealing multi-pane window, with different colors, hues, and surface etching designs and the masking of seams between monoliths.

Finally, the authors have recognized that there is a trade-off between thermal insulation and optical performance. They have stated that their ongoing work includes incorporating gas layers into the design to retain both thermal insulation and improve optical performance. They have also noted that evacuation, which has not been explored in the study, could further improve the thermal performance of future designs.

Further Reading

Carroll, M.K et al. (2022) Aesthetic Aerogel Window Design for Sustainable Buildings [online] Sustainability 14(5) 2887 | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/5/2887

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.