By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 8 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 8 2022In an article recently published in the open-access journal Materials, researchers discussed the incorporation of sludge water in high-temperature steam cured green and high-performance concrete based on an early age performance analysis.

Study: Early-Age Performance Analysis of Sludge Water Incorporation in High-Temperature Steam Cured Green High-Performance Concrete. Image Credit: JonShore/Shutterstock.com

Background

In recent decades, the concrete construction sector has experienced tremendous growth, which is likely to continue to grow in the future. However, the expeditiously growing concrete construction industry has imposed a significant environmental burden.

To solve the problem related to the vast amount of water required by the developing concrete construction industry, especially given the world's increasing scarcity of freshwater resources, an appropriate freshwater substitute for the concrete building is in high demand. The discharge of sludge water into neighboring natural water bodies is not beneficial to the long-term growth of waterworks and will harm the water environment and ecology.

Cement-based materials have a lot of potential for immobilizing harmful ions inside the specimen. Using them to dispose of sludge water from the water production procedure is an appropriate way to not only alleviate the crisis of freshwater but also solve the sludge water disposal problem due to its extremely toxic properties. For decades, high-performance concrete with exceptional mechanical qualities and long durability has been proposed to improve the performance of cement-based materials.

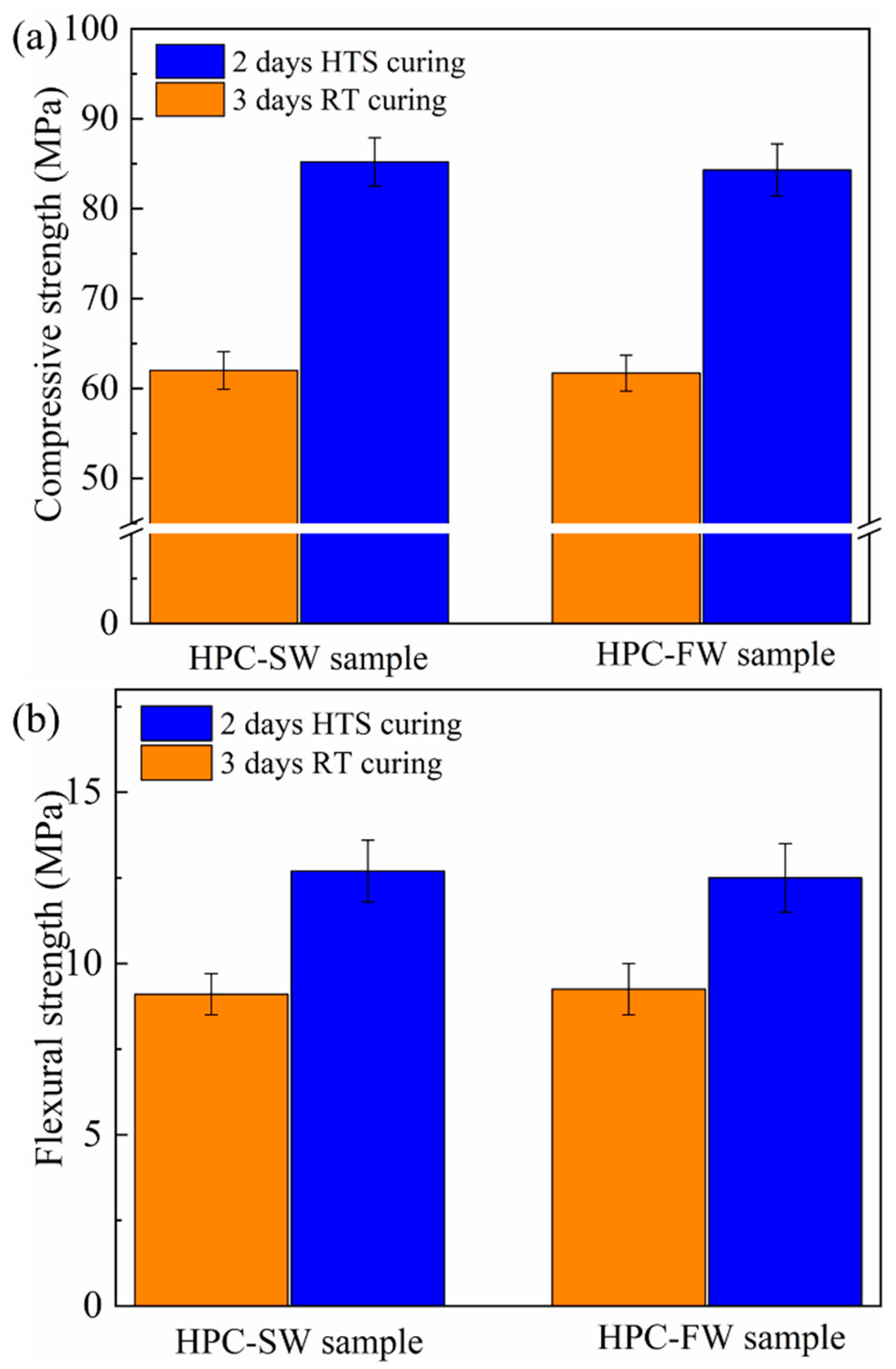

Mechanical properties of HPC-FW and HPC-SW specimens cured by different curing methods: (a) compressive strength and (b) flexural strength. Image Credit: Qi, B et al., Materials

About the Study

In the present study, the authors reported the utility of sludge water (SW) containing sufficient sulfate ions (SO42-) as a replacement of freshwater (FW) in the preparation of green high-performance concrete (GHPC). A thorough examination was carried out to assess the early-age performance of GHPC specimens mixed with SW (GHPC-SW).

To prepare GHPC-SW specimens, high-temperature steam curing (HTS) was utilized. This work demonstrated the resource-saving and environmentally responsible use of SW in the concrete building industry. The study also showed how sludge water could completely replace freshwater in the preparation of high-performance concrete for steam curing at high temperatures.

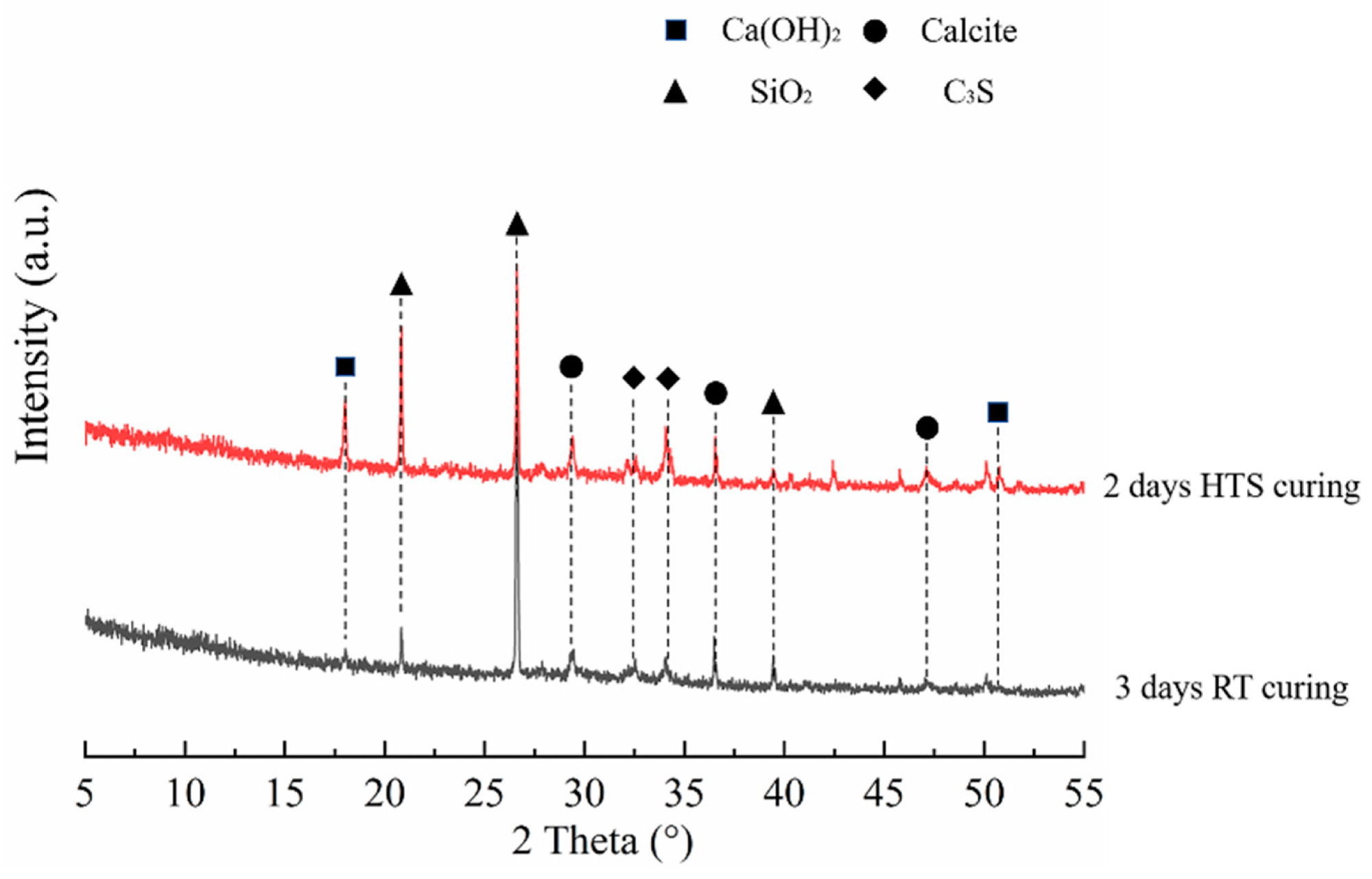

Furthermore, X-ray diffraction (XRD) and thermogravimetric (TG) measurements were carried out to show that HTS curing improved the hydration degree of GHPC-SW specimens significantly. The impact of high-temperature steam curing on the immobilization of damaged ions in sludge water was determined in order to improve the specimen's performance for using sludge water in cement-based products.

To determine the influence of sludge water addition on specimen strength development, the mechanical characteristics of specimens with various curing procedures and different types of mixing water were measured. Various microscopic investigations such as XRD, TG, and mercury intrusion porosimetry (MIP) were performed to study the microstructure evolution of the specimens containing sludge water cured using various curing procedures.

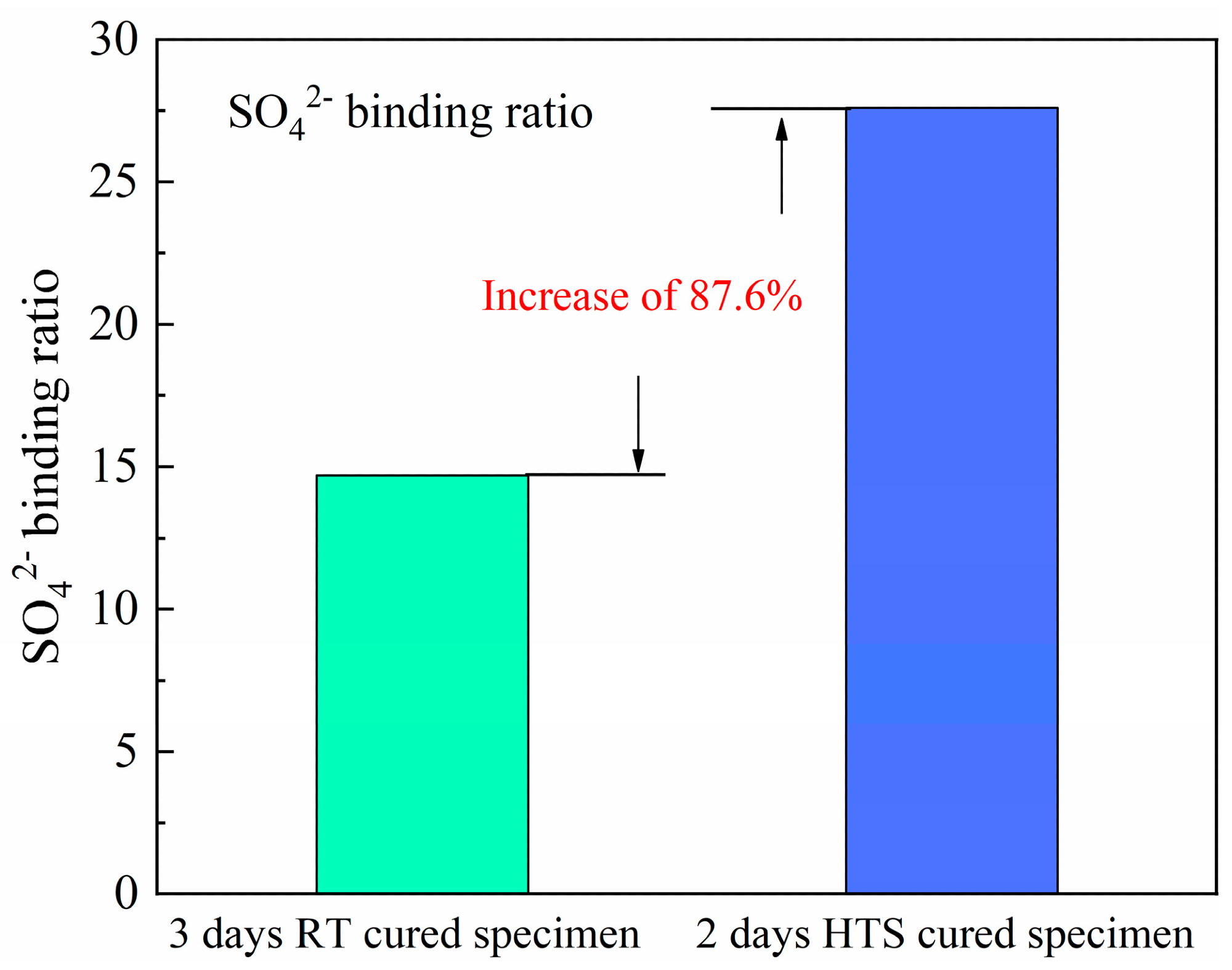

Additionally, the hazardous SO42- ion content present inside the specimen was tested to see how high-temperature steam curing affected the specimen's ion binding ratio. The impact of various curing regimes on HPC-SW specimens was thoroughly investigated.

XRD patterns of HPC-SW specimens cured by HTS curing and SC. Image Credit: Qi, B et al., Materials

Observations

In the MIP analysis, the specimens treated by HTS curing had a more refined pore structure with less hazardous pores. The results showed that the compressive strength of the GHPC-SW specimen cured by HTS for two days was 85.2 MPa, which was 34% greater than the compressive strength of the GHPC-SW specimen cured by normal curing for 3 days. The mechanical property results showed that the addition of SW had no negative impact on the strength formation of HPC specimens.

Moreover, the specimen cured by SC curing had a compressive strength of 62 MPa, and the HTS-cured HPC-FW specimen had a compressive strength of up to 84.3 MPa. The flexural strength of the HPC-SW specimen cured by HTS curing was 12.7 MPa, which was also equal to the 12.5 MPa flexural strength of the HTS cured HPC-FW specimen. The HPC-SW and HPC-FW specimens treated by SC curing had flexural strengths of 9.1 MPa and 9.25 MPa, respectively.

The SO42- binding ratio of specimens cured by SC was 14.7 and the SO42- binding ratio of the HTS treated specimen was 27.6% which represented an increase of 87.6% above the SO42- binding ratio of specimens cured by SC. The integration of SW had no negative impact on the mechanical characteristics of HPC specimens, and the mechanical properties of HPC specimens were unaffected by the addition of SW.

SO42− binding ratios of HPC−SW specimens cured by different curing regimes. Image Credit: Qi, B et al., Materials

Conclusions

In conclusion, this study elucidated the potential of sludge water as a replacement for fresh water in HPC specimens. The flexural strength of HPC specimens followed the same development pattern as the compressive strength. Microstructural investigations showed that HTS curing effectively increased hydration and refined the pore structure of HPC-SW specimens, indicating that the combination of HTS curing and sludge water incorporation for green concrete structure construction should be prioritized.

Overall, the results of the SO42- binding ratio emphasized that HTS curing should be prioritized for enhancing the ion immobilization effectiveness of HPC specimens. The authors believe that this will result in the safe discharge of sludge water as concrete mixing water.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Qi, B., Early-Age Performance Analysis of Sludge Water Incorporation in High-Temperature Steam Cured Green High-Performance Concrete. Materials 15(5), 1912 (2022). https://www.mdpi.com/1996-1944/15/5/1912