In the never-ending quest to store maximum energy into batteries without compromising their volume or weight, solid-state batteries stand out as a promising technology.

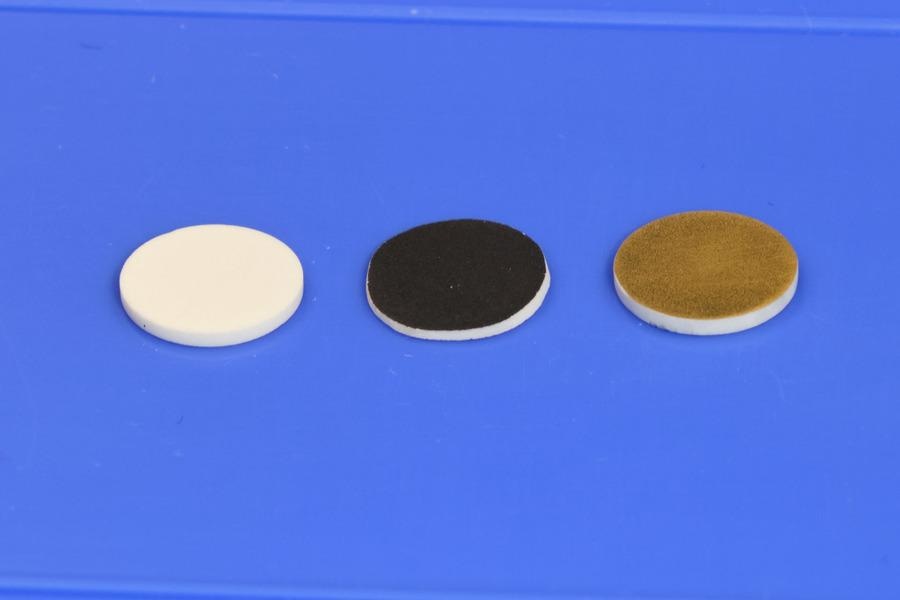

These discs were used for testing the researchers’ processing method for solid-electrolyte batteries. On the left, a sample of the solid electrolyte itself, a material known as LLPO. At center, the same material coated with the cathode material used in their tests. At right, the LLPO material with a coating of gold is used to facilitate measuring its electrical properties. Image Credit: Pjotrs Žguns.

These discs were used for testing the researchers’ processing method for solid-electrolyte batteries. On the left, a sample of the solid electrolyte itself, a material known as LLPO. At center, the same material coated with the cathode material used in their tests. At right, the LLPO material with a coating of gold is used to facilitate measuring its electrical properties. Image Credit: Pjotrs Žguns.

In these batteries, the standard liquid electrolyte that transports charges to and fro between the electrodes is substituted with a solid electrolyte layer. Such batteries could not only provide twice as much energy for their size but could also almost entirely remove the fire hazard associated with present-day lithium-ion batteries.

But there has been one setback regarding solid-state batteries: Instabilities found at the boundary between the solid electrolyte layer and the two electrodes on either side can greatly reduce the lifespan of such batteries. Few studies have used exclusive coatings to enhance the bonding between the layers, but this adds the expense of additional coating steps in the fabrication process.

Now, a group of scientists at MIT and Brookhaven National Laboratory has formulated a way of realizing results that equal or exceed the durability of the coated surfaces, but with no requirement for any coatings.

The new technique requires removing any carbon dioxide found during a critical manufacturing step, known as sintering, where the battery materials are heated to form bonding between the cathode and electrolyte layers, which are composed of ceramic compounds.

Although the quantity of carbon dioxide present is vanishingly small in air, measured in parts per million, its effects can be dramatic and damaging. Performing the sintering step in pure oxygen forms bonds that match the performance of the superior coated surfaces, without that additional cost of the coating, the scientists explain.

The findings have been reported in the journal Advanced Energy Materials, in an article by MIT doctoral student Younggyu Kim, professor of nuclear science and engineering and of materials science and engineering Bilge Yildiz, and Iradikanari Waluyo and Adrian Hunt at Brookhaven National Laboratory.

Solid-state batteries have been desirable for different reasons for a long time. The key motivating points for solid batteries are they are safer and have higher energy density.

Bilge Yildiz, Professor of Nuclear Science and Engineering and Materials Science and Engineering, MIT

According to Yildiz, solid-state batteries have not been able to reach mass commercialization because of two factors: the lower conductivity of the solid electrolyte, and the interface instability problems.

The conductivity problem has been effectively handled, and reasonably high-conductivity materials have already been verified, according to Yildiz. But surpassing the instabilities that appear at the interface has been quite challenging.

These instabilities can happen during both the production and the electrochemical operation of such batteries, but for the time being, the scientists are concentrating on the manufacturing, and particularly the sintering process.

Sintering is necessary because if the ceramic layers are just pressed onto each other, the contact between them is far from suitable; there are several gaps, and the electrical resistance across the interface is high.

Sintering, which is typically performed at temperatures of 1,000 °C or above for ceramic materials, causes atoms from each material to move into the other to develop bonds. The team’s experiments revealed that at temperatures anywhere over a few hundred degrees, damaging reactions occur that raise the resistance at the interface — but only if carbon dioxide is present, even in minute amounts.

They showed that avoiding carbon dioxide, and especially sustaining a pure oxygen atmosphere during sintering, could form excellent bonding at temperatures up to 700 degrees, with none of the damaging compounds created.

The performance of the cathode-electrolyte interface made using this technique, Yildiz says, was “comparable to the best interface resistances we have seen in the literature,” but those were all accomplished using the additional step of applying coatings. “We are finding that you can avoid that additional fabrication step, which is typically expensive.”

The potential benefits in energy density that solid-state batteries offer result from the fact that they allow the use of pure lithium metal as one of the electrodes, which is a lot lighter than the presently used electrodes composed of lithium-infused graphite.

The researchers are currently exploring the next segment of the performance of such batteries, which is how these bonds hold up in the long term during battery cycling. In the meantime, the new results could possibly be applied rapidly to battery production, she says.

“What we are proposing is a relatively simple process in the fabrication of the cells. It doesn't add much energy penalty to the fabrication. So, we believe that it can be adopted relatively easily into the fabrication process,” and the additional costs, they have calculated, should be insignificant.

Large companies such as Toyota are already involved in commercializing early models of solid-state lithium-ion batteries, and these new findings could rapidly help such companies enhance the economics and resilience of the technology.

The study was supported by the U.S. Army Research Office through MIT’s Institute for Soldier Nanotechnologies. The team made use of the facilities supported by the National Science Foundation and facilities at Brookhaven National Laboratory supported by the Department of Energy.

Journal Reference:

Kim, Y., et al. (2022) Avoiding CO2 Improves Thermal Stability at the Interface of Li7La3Zr2O12 Electrolyte with Layered Oxide Cathodes. Advanced Energy Materials. doi.org/10.1002/aenm.202102741.