A group of researchers from Johns Hopkins University has developed a shock-absorbing material that protects like a metal but is lighter, tougher and reusable. Helmets, body armor and vehicle and aircraft equipment could all potentially benefit from the new foam-like substance.

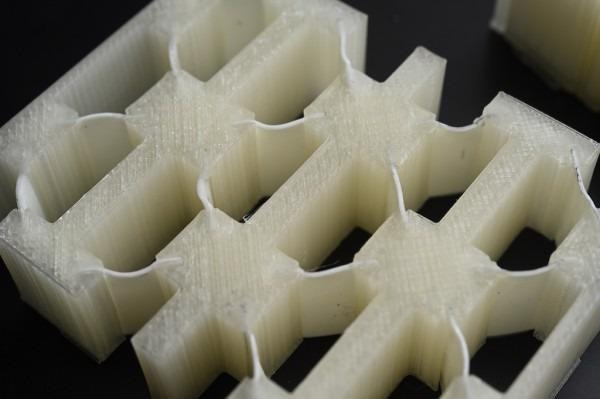

Johns Hopkins researchers studied the energy-absorbing capability of liquid crystal elastomers. Image Credit: Johns Hopkins University.

Johns Hopkins researchers studied the energy-absorbing capability of liquid crystal elastomers. Image Credit: Johns Hopkins University.

We are excited about our findings on the extreme energy absorption capability of the new material. The material offers more protection from a wide range of impacts, but being lighter could reduce fuel consumption and the environmental impact of vehicles while being more comfortable for protective gear wearers.

Sung Hoon Kang, Study Senior Author and Assistant Professor, Mechanical Engineering, Johns Hopkins University

Kang, who is also a fellow at the Hopkins Extreme Materials Institute, intended to develop a material that would absorb even more energy than present automobile bumpers and helmet padding. Kang discovered that the standard materials utilized for these life-saving devices do not operate well at fast speeds and are not always reusable.

With high energy-absorbing liquid crystal elastomers (LCEs), which have mostly been employed in actuators and robotics, the research team was able to increase strength while lowering weight.

Objects weighing 4–15 pounds were struck at speeds of up to 22 miles per hour during studies to evaluate the material’s impact resistance. Due to the limitations of the testing equipment, the tests were restricted to 22 miles per hour, but the team is sure that the padding could safely absorb much higher impacts.

Kang and his colleagues are considering partnering with a helmet manufacturer to develop, build and test next-generation helmets for athletes and the military.

The study was published in the Advanced Materials journal.

The Johns Hopkins group also included Lichen Fang, a former graduate student; Thao (Vicky) Nguyen, a professor of mechanical engineering; Beijun Shen, a graduate student; Seung-Yeol Jeon, a former postdoctoral researcher at the Hopkins Extreme Materials Institute; and Zeyu Zhu, a former graduate student; and Nicholas A. Traugutt, and Christopher M. Yakacki, both from the University of Colorado Denver.

The study was funded in part by the Army Research Office (Grant Number W911NF-17-1-0165) and the Johns Hopkins University Whiting School of Engineering Start-Up Fund.

Drop tower test

Liquid crystal elastomer structure tested in drop tester machine. Video Credit: Johns Hopkins University.

Journal Reference:

Jeo, S.-Y., et al. (2022) Synergistic Energy Absorption Mechanisms of Architected Liquid Crystal Elastomers. Advanced Materials. doi.org/10.1002/adma.202200272.