By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 22 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 22 2022In an article recently published in the open-access journal Materials, researchers discussed the development of construction materials using wastewater and its potential applications in the circular economy for the mass production of bricks.

Study: Development of Construction Material Using Wastewater: An Application of Circular Economy for Mass Production of Bricks. Image Credit: Poh Smith/Shutterstock.com

Background

To make burnt clay bricks, a mix of water and clayey soil is needed. People from all over the world and throughout history have favored stone, timber, and mudbrick as basic building materials. Clay bricks were used in ceilings more commonly than stone because they are lighter and quicker to prepare, and they allow for easier row alignment and thickness control. Clay bricks' architectural applications as well as their chemical and mechanical properties have been previously explored. However, only a few studies go into great depth on how bricks are made.

![Water management cycle [20].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_58596_1647945468045441.jpg)

Water management cycle. Image Credit: Ghafoor, S et al., Materials

One of the most important components in construction materials is water. During the production of burnt clay bricks, billions of gallons of clean water are wasted. Similarly, the squandering of clean water is a worldwide problem. Typically, potable water is utilized in the construction process; however, wastewater might be used instead. Previously, wastewater had only been used in the production of concrete, and only olive oil mill effluent had been studied for clay brick production.

About the Study

In this study, the authors discussed the development of burnt clay bricks by using wastewater and compared them to clay bricks made with groundwater using the traditional procedure. According to the American Society for Testing and Materials, all burnt clay brick specimens were subjected to destructive (i.e., compressive strength (CS)) and non-destructive (i.e., ultrasonic pulse velocity (UPV)) testing (ASTM) testing. Physical (i.e., dimension) and durability (i.e., water absorption, efflorescence, and so on) testing were also carried out.

The team used wastewater to make bricks with similar or superior strength in comparison to groundwater-fired clay bricks. Both destructive and non-destructive tests were done and assessed as part of the experimental inquiry. The impact of wastewater on the strength and development of burnt clay bricks was demonstrated.

The authors used domestic wastewater, the world's largest source of wastewater, for the mass manufacture of clay bricks. The potential of this process to run concurrently with the circular economy idea was assessed. The impact of replacing groundwater with wastewater was also illustrated. Regression analysis was used to explore the link between destructive and non-destructive testing outcomes.

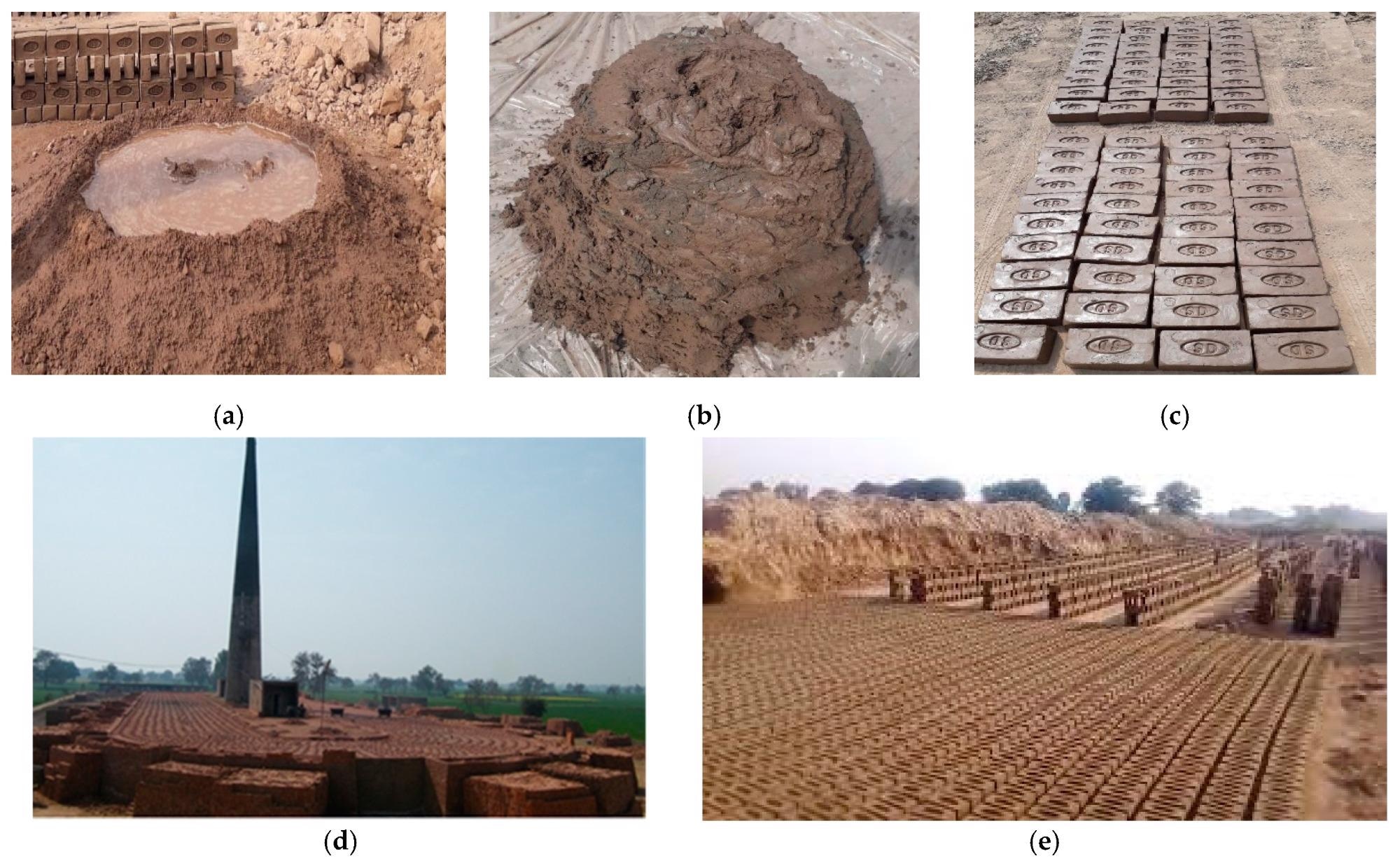

Burnt fired clay manufacturing: (a) Wet mixing and voids filling of clay. (b) Clay lump. (c) Sun drying of demolding specimens. (d) Fired in standard Hoffmann kiln. (e) Mass production of clay bricks. Image Credit: Ghafoor, S et al., Materials

Observations

The addition of various types of waterways, such as groundwater and wastewater, resulted in the development of sustainable and eco-friendly brick material. The outcomes from wastewater bricks were 19% better than those from ground surface water bricks. The UPV findings showed that mixing and preparing burned clay bricks with wastewater facilitated the production of structural and long-lasting construction materials. All of the estimated UPV values were between 3500 and 4100 m/s. Groundwater bricks had a compressive strength of about 11.50 MPa. Only around 17% of the water was absorbed by all of the prepared bricks.

Physical and durability analyses demonstrated the efficacy of wastewater brick manufacture. The water absorption of the bricks prepared from wastewater was 12%, which was in accordance with the ASTM C-62 standards. The R2 of the equation generated using the proposed model was 0.71.

All the prepared brick types satisfied the standard requirements for physical and durability properties. In comparison to groundwater-fired clay bricks, the testing results of wastewater bricks were 15–25% higher.

The results demonstrated the successful manufacture of baked clay bricks using groundwater and wastewater which proved that wastewater could be used to replace groundwater. It was also determined that these bricks can be utilized for boundary walls, flooring, and other non-structural aspects.

![Ultrasonic pulse velocity working flow diagram [43].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_58596_16479454910566347.jpg)

Ultrasonic pulse velocity working flow diagram. Image Credit: Ghafoor, S et al., Materials

Conclusions

In conclusion, this study elucidated that wastewater can be successfully used for the mass production of bricks in order to meet circular economy aims. It was observed that a million gallons of subsurface water could be saved by manufacturing bricks with wastewater.

The results demonstrated that to achieve circular economy aims, a substantial amount of wastewater could be utilized to make bricks, and pure water could be saved. The authors believe that this research will aid in the development of low-cost bricks as well as in the conservation of pure water. They also emphasized that the proposed strategy is also beneficial to long-term development, which is a top priority for the entire planet.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Ghafoor, S., Hameed, A., Shah, S.A.R., et al. Development of Construction Material Using Wastewater: An Application of Circular Economy for Mass Production of Bricks. Materials 15(6) 2256 (2022). https://www.mdpi.com/1996-1944/15/6/2256